7

6.0 Setup and assembly

Remove the sander from its crate and inspect for

damage to ensure all parts are intact. Any damage

should be reported to your distributor and shipping

agent immediately upon discovery.

Before proceeding with installation, read your

instruction manual thoroughly. Familiarize yourself

with correct set-up, maintenance and safety

procedures.

6.1 Shipping contents

1 WideBeltSander

1 InfeedRollerAssemb ly

1 OutfeedRollerAssemb ly

1 SideSupport

1 SandingBelt

1 Toolbox,containingoilgun,doorlatches,and

drawbar(forthegraphitepad)

6.2 Installation

If using a forklift, run the forks between the upper

cabinet and the conveyor belt. Level the machine

and bolt it to the floor with high quality anchor bolts

through the mounting holes located on the four

corners of the base.

Remove the protective coating from the rollers with

a soft cloth moistened with a good commercial

solvent. DO NOT USE acetone, gasoline, lacquer

thinner or any type of flammable solvent. Do not

use an abrasive pad.

6.3 Assembly

1. Attach the infeed and outfeed roller

assemblies with sixteen 5/16" x 2" hex head

screws and spring washers.

2. Mount the side support with two hex cap

screws and flat washers.

3. Insert the door latches into the slots on the

cabinet doors.

4. Assemble the sanding belt to the rollers. Make

sure the arrow on the belt matches the rotation

of the rollers.

7.0 Electrical connections

All electrical connections should

be made by a qualified electrician in compliance

with all relevant codes. Failure to comply may

result in serious injury and/or damage to the

machine and property. The machine must be

properly grounded.

1. A cable of the proper gauge should be used to

connect the sander to the power supply.

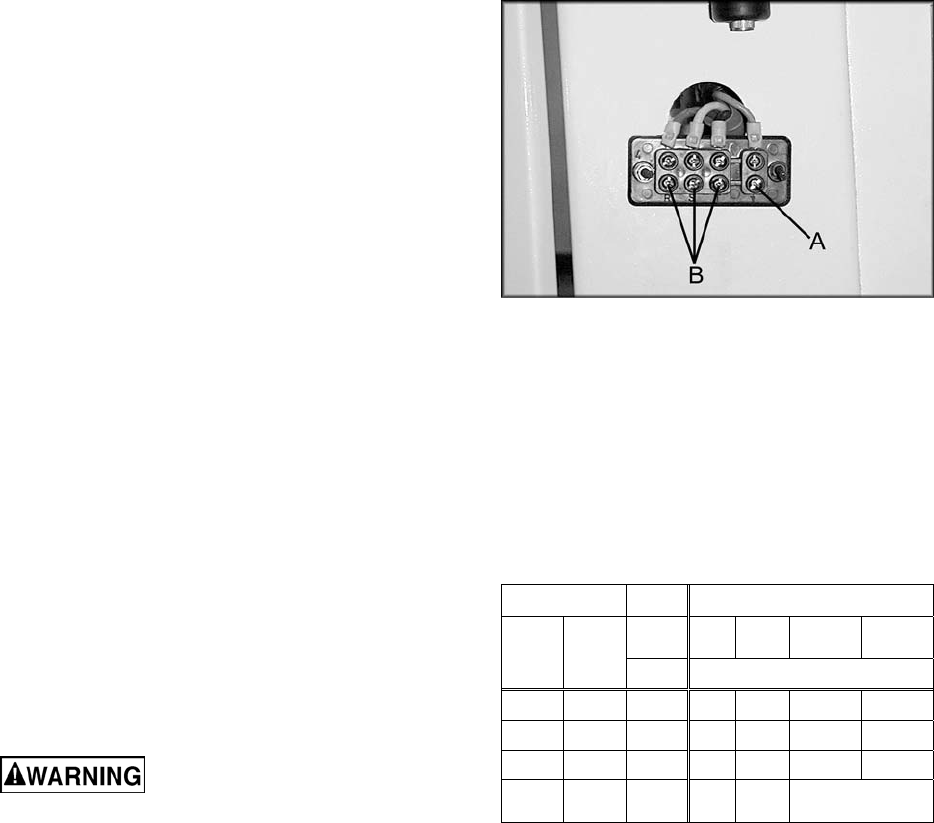

2. Remove the wiring cover and attach the

ground wire (A), Figure 1.

3. For 3 Phase: Connect the three power leads

(B) to the wiring board.

For 1 Phase: Connect the two power leads to

the wiring board.

4. This machine should be hard wired into a

dedicated circuit with a properly rated breaker

according to your local code.

5. Replace wiring cover.

6. Turn on the feed belt and verify that the belt

feeds into the machine. It if turns toward the

user, disconnect the machine from the power

source and switch only two of the power leads

(on 3 Phase machine).

Figure 1

7.1 Voltage conversion

The 3 Phase machine is pre-wired for 230V

operation. If 460V is needed, see the wiring box

cover on the reduction motor and the main motor.

BOTH motors must be switched if changing from

230V to 460V. The transformer, behind the control

panel, must also be switched from 230V to 460V.

7.2 Extension cords

Amp Rating Volts Total length of cord in feet

More

Than

Not

More

Than

120

240

25

50

50

100

100

200

150

300

AWG

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

Recommended

Extension Cord Recommendations

Table 1

USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.