8

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

8.0 Adjustments

Disconnect sander from power

source before making adjustments.

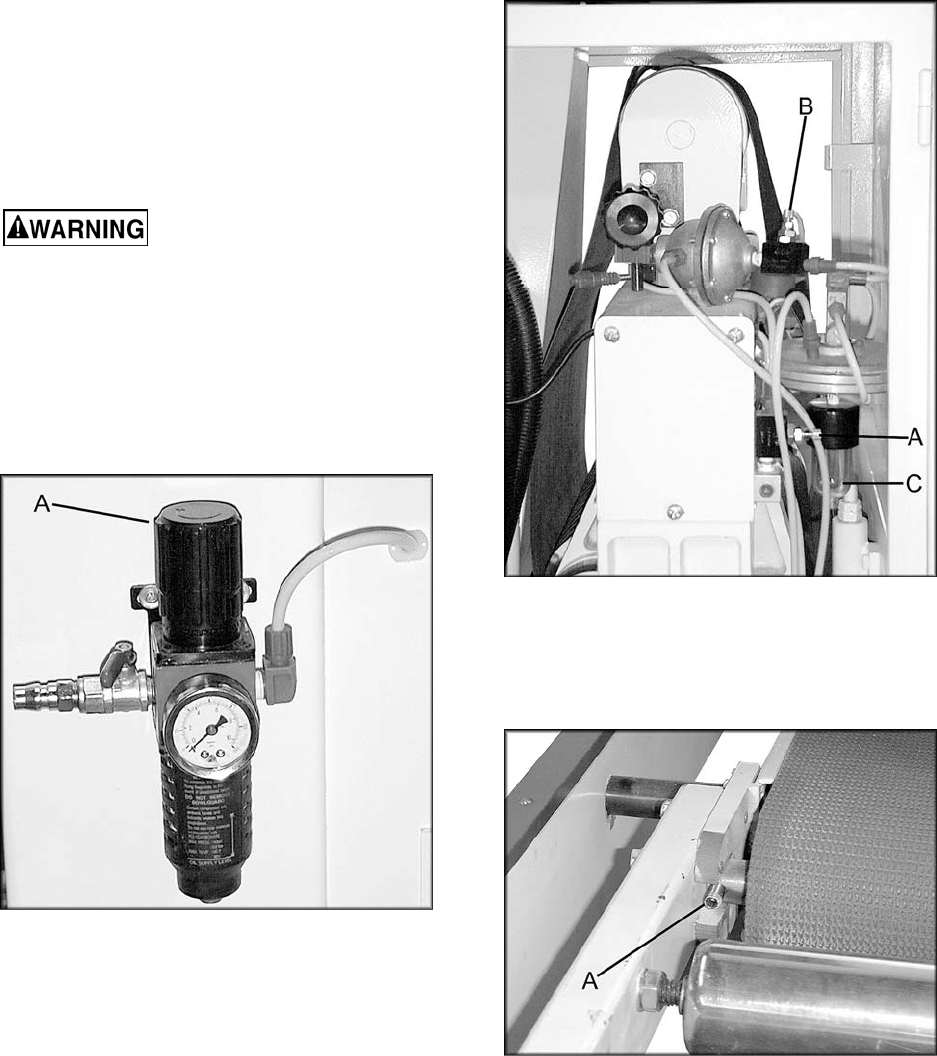

8.1 Air control

Connect the machine to an air hose. The air

pressure that flows into the filter can be adjusted

with the knob (A), Figure 2. Normal working air

pressure should be set at 75 psi, which can be

read on the pressure gauge.

Figure 2

8.2 Sanding belt tracking and

oscillation

The tracking and oscillation of your sander are pre-

adjusted at the factory. However, should

adjustment be required, do the following:

1. Adjust the air valve (A), Figure 3, to control the

tracking sensitivity.

2. The oscillation speed can be controlled by

adjusting the top air valve (B).

3. Empty the glass container (C) as needed.

NOTE: There is a limit switch at both ends of the

upper roller. If the sanding belt comes in contact

with these limit switches, the brakes will be

activated.

Figure 3

8.3 Feed belt tracking and tension

Tracking and tension for the feed belt is controlled

by two socket set screws on each side of the belt

(A) as shown in Figure 4.

Figure 4

8.4 Adjusting table parallel to

sanding surface

The table comes pre-adjusted from the factory.

Check its parallelism by running a 16" wide piece

of plywood through the sander. Use a pair of

calipers to measure the thickness remaining on

both sides.

Adjust the parallelism using the four hex. screws

(A), under the table base. See Figure 5.