15

Castor system adjustment

Retractable castors can be extended permitting the

saw to be moved:

1. Loosen the lock knob (A) on the side

handwheel (C).

2. Pull the handwheel out (F).

3. Turn the handwheel (C) clockwise to extend

the castors, raising the saw.

Note: Because of the weight of the machine,

both hands will be needed to turn the

handwheel. Raise the saw just enough to

permit moving to another location.

When the saw has been repositioned:

4. Retract the castors by turning the

handwheel (C) counterclockwise.

5. Push the handwheel in (F) and tighten the lock

knob (A).

Zero-Clearance Insert Setup

Under normal operations where the standard table

insert (which is provided) is used, the top edge of

the saw blade will come to rest approximately 1/8"

below the table surface when the blade height is

positioned all the way down.

In situations where a zero-clearance insert is

desired, the saw blade may be lowered further for

accommodation of inserts that have potential

clearance issues with the blade. This is done as

follows:

1. Remove the guard and pawl (Figure 9,

Items C, E).

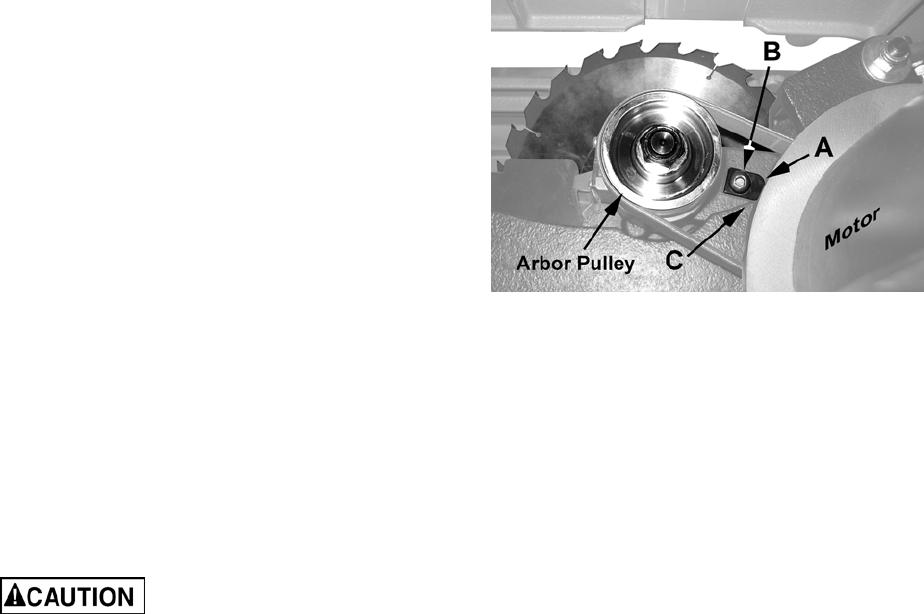

2. Open the side cover and locate the blade depth

stop (A, Fig. 12) located between the arbor

pulley and motor.

3. Using a 6mm hex wrench, loosen the locking

screw (B, Fig. 12).

4. This will allow the depth stop to swing free and

the saw blade to be adjusted lower.

5. With the height adjust handwheel (B, Fig. 11),

lower the saw blade all the way.

The zero-clearance insert can now be placed into

the table opening without contacting the saw blade.

Never use a zero-clearance

insert with the saw blade in a tilted position.

Never operate the saw without the blade guard,

riving knife and anti-kickback pawls for

operations where they can be used.

Figure 12

When the standard insert is to be used again, the

saw blade must be readjusted as follows:

6. With the height adjust handwheel (B, Fig. 11),

adjust height of the saw until the top of the saw

blade is 1/8" below the top of the table.

7. The blade depth stop (A, Fig. 12) should be

resting against the trunnion (C, Fig. 12). Verify

that this is the case; then tighten the locking

screw (B, Fig. 12).

8. Replace the standard insert, pawl and blade

guard.