19

Note: These screws are accessible through

openings on the floating clamp block (B)

located diagonally on either side of the lock

handle (A). They secure the fixed clamp

block (C) to the riving knife extension plate (F).

Loosening these screws (E) will allow the fixed

clamp block (C) to slide back and forth on the

extension plate (F).

3. Slide the fixed clamp block (F) toward or away

from the saw blade as required.

4. Tighten the socket head button screws (E).

5. Reinsert the riving knife; tighten the lock handle

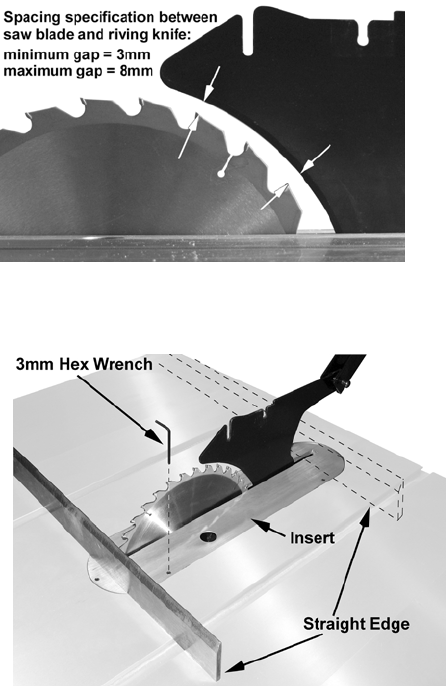

(A, Fig. 18) and check that the saw blade/knife

gap is between 3 - 8mm (Figure 20).

Note: Attempt to make the gaps as even as

possible.

Insert Adjustment

Adjust the setscrews in the insert with a 3mm hex

wrench (Figure 21) to ensure that the insert is

stable and flush with the table top.

Arbor and Arbor Bearing Removal

The saw arbor is press fit in the saw raising arm

housing. If the arbor needs to be removed for

bearing replacement, it should be done by a

qualified service technician. Call your customer

service representative at the phone number on the

front cover.

Figure 20

Figure 21