19

Periodically:

1. The carriage is designed to move smoothly

along the guide tubes. If the guide tubes

become caked with dust, the carriage may

not slide evenly or become stuck.

Occasionally clean the guide tubes with a

damp cloth and apply a dry lubricant such

as a spray silicone.

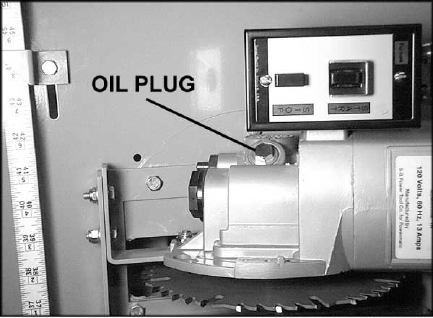

2. Rotate the motor to horizontal position and

check the motor oil level at the plug. Figure

22 shows the location of the oil plug. If low,

fill with SAE 70 or 80 gear oil to proper level.

The gear oil should be changed at least

once a year, or more frequently if the panel

saw receives heavy use.

Every six months:

1. Examine the motor brushes, and replace as

necessary.

2. Inspect and clean gears, spindles, bearings,

housing, etc.

3. Inspect switch, cord, armature, etc.

4. Test to ensure proper mechanical and

electrical performance.

Figure 22