5

B.

DAILY OPERATIONS MAINTENANCE CHECKS:

1. Battery

A. Check for corroded and loose terminals. A white powder substance will be present if there is any existing

corrosion.

B. Check for loose battery tie-downs.

C. Visually inspect for any cracks or damage to the casing.

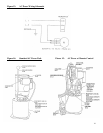

2. Charger

A. Inspect wire connections.

B. Check power cord for nicks/damage.

C. Check charger for proper mounting.

3. Hydraulic System

A. Inspect pump and cylinder for oil leaks.

B. Check hydraulic oil level. Unscrew breather plug on power unit with forks platform fluid will be ½ - ¾ of an

inch from opening all the way down.

C. Check hydraulic fittings and hoses.

4. Frame Assembly

A. Check floor lock.

B. Check placement of safety screen.

C. Check chain roller assembly.

D. Check for any worn or damaged parts.

SECTION 5

MAINTENANCE

A.

INSTRUCTIONS:

• Grease wheels and casters at least once a month to maintain easy roll of lift.

• Use only Hydraulic Oil (or #10 Motor Oil) in the hydraulic system. NEVER USE HYDRAULIC BRAKE FLUID.

• Do not overload your lift.

B.

MONTHLY MAINTENANCE CHECKS:

1. Battery

A. Clean terminals.