❲

19

❳

8. Maintenance

MA1

every every every

25 50 100

system/compornent procedure before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see

■ADJUSTING

replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.17)

if necessary

clean and readjust

GAP: .025in(0.6~0.7mm)

spark plug ✔

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

replace if

cutting parts ✔

something's wrong

debris guard make sure to attach ✔

gear case / cutter case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

E

N

G

I

N

E

S

H

A

F

T

■ MAINTENANCE CHART

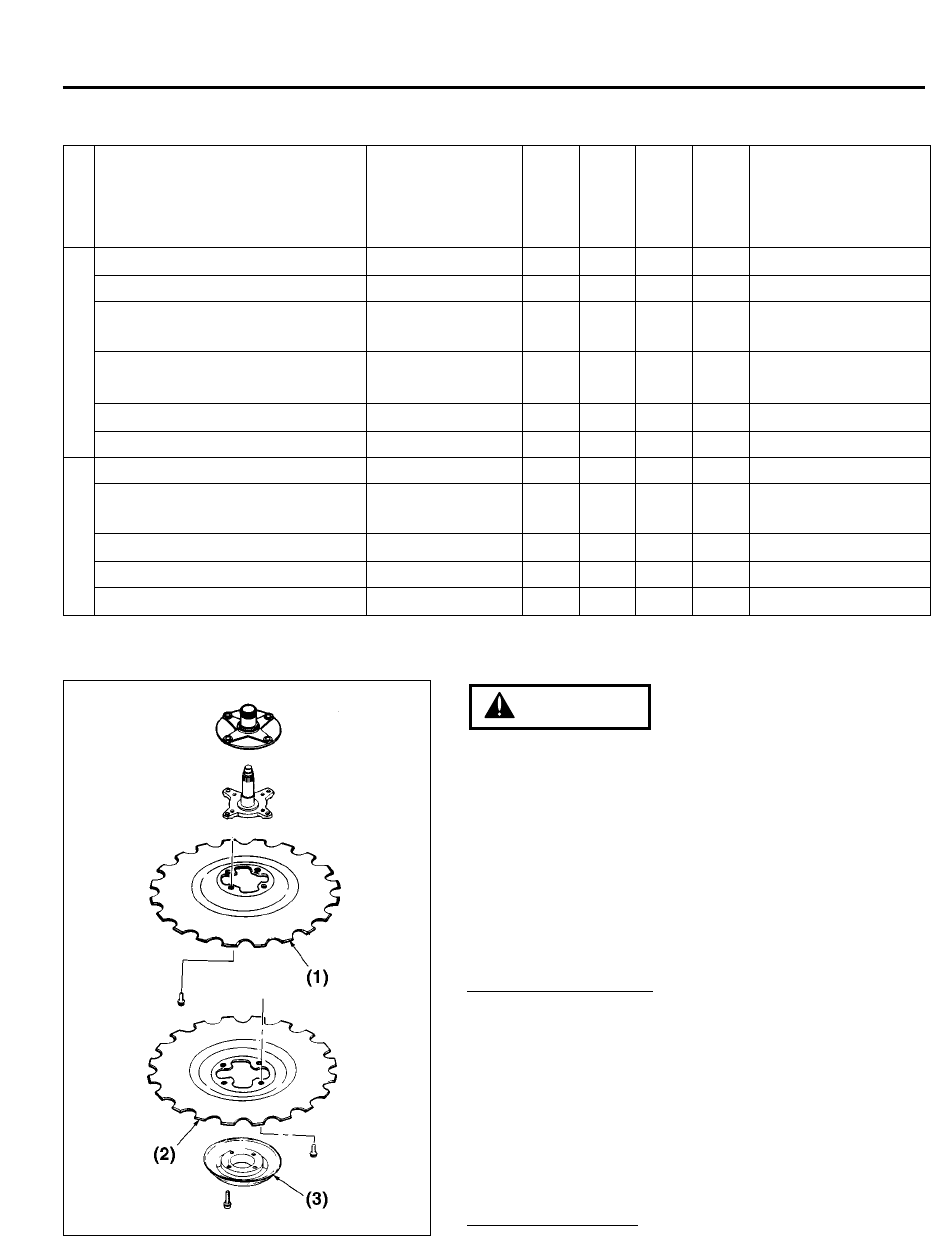

■ BLADE MAINTENANCE

Use protective gloves whenever inspecting,

removing, sharpening, and installing the blade.

• Wipe off dust and dirt attached to the blade, and

oil it after every use.

• As the extent of wear differs by each cutter

depending on use conditions, rotate the blade

position at intervals.

To Remove Blades: (MA1)

1. Turn over the machine and remove the bottom

cover by removing the four cross-slotted screws.

2. Loosen the four socket screws and remove the

lower blade.

3. Loosen the four socket screws and remove the

upper blade.

(1) Upper blade (2) Lower blade (3) Bottom cover

To Install Blades:

The upper and lower blades are interchangeable.

When fastening the blade mounting screws, torque

them uniformly (Torque: 100 to 130 in-lbs)(Torque:

11.3 ~ 14.8 N.m.).

WARNING