• Raise the cut-off saw from the kerf of the work-

piece prior to releasing the trigger switch. Less like-

ly for saw blade to bind.

Description, Specifications and

Standard Equipment

Description

The RIDGID 614 Dry Cut Saw is designed to cut ferrous

and non-ferrous pipe and irregular materials such as the

following:

• Gas pipe, lining tube, electrical pipe and conduit

and PVC pipe.

• Steel angle, channel and bar

• Aluminum frame, curtain rail and a variety of interi-

or decoration material

A two-lever vise clamps the workpiece and allows an

angle cut from 45º to 90º. The motor operates on a

115 volt, single phase, 50-60 Hertz, AC current.

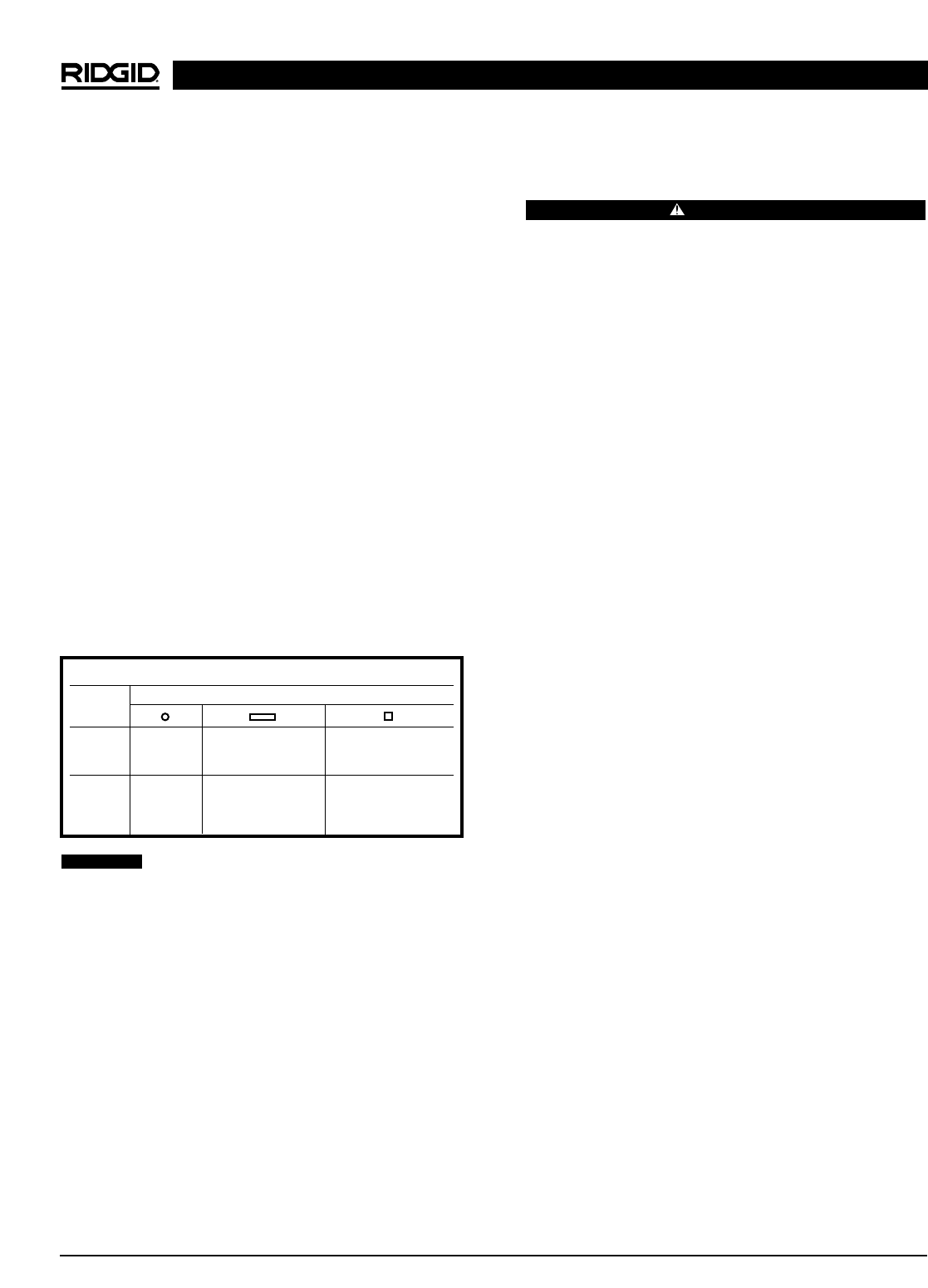

Specifications

Cutting Capacity:

Cutting of larger shapes not recommended.

Motor:

Type............................Universal

Volts............................115AC, 50-60Hz

Amps...........................15 Amps

No Load Speed...........1300 RPM

Blade Size .....................14″ x .087″ x 1″

Weight ...........................49 lbs.

Standard Equipment

• Dry Cut Saw

• 14″ Blade (Installed)

• Two (2) Allen Wrenches

Ridge Tool Company

4

Inspect Dry Cut Saw

WARNING

To prevent serious injury, inspect your Dry Cut

Saw on a regular basis. The following inspection

procedures should be performed before each use

of the tool:

1. Inspect the power cord and plug for damage. If the

grounding prong is missing or the cord is damaged,

do not use the tool until the cord has been replaced.

2. Make sure the switches turn the tool ON and OFF. If

broken, do not use until they are replaced.

NOTE! Switch Action (Figure 4)

There is a LOCK-OFF switch button on the handle. To

start the tool, first depress the LOCK-OFF switch button

and then pull the trigger. The trigger will not work before

the LOCK-OFF switch button is depressed.

3. Inspect the saw for any broken, missing, misaligned

or binding parts as well as any conditions which may

affect the safe and normal operation of the tool. If any

of these conditions are present, do not use the tool

until the problem has been repaired. Do not use dull

or damaged blades.

4. Make sure all guards are in place and in working

order.

5. Clean any oil, grease or dirt from the handles. This

reduces the risk of injury due to the tool slipping

from your grip.

6. Use only accessories recommended for your tool.

Accessories used for other tools may be hazardous

when used on this saw and lead to serious injury.

7. Inspect the cutting edges of your saw blade. If nec-

essary, replace prior to using. Dull or damaged cutting

edges can lead to injury, tool breakage or exces-

sive heat build-up in the workpiece and the tool.

Check that the speed rating of the saw blade is at

least 1300 RPM.

8. Clean metal shavings and other debris from the chip

tray located at the rear of the saw (Figure 1).

614 Dry Cut Saw

Model 614 Capacity Chart

Cutting Workpiece Geometry

Angle

90˚ Cuts 5″ 3

3

/

4

″ x 7″ 4

1

/

2

″ x 4

1

/

2

″

130mm 95mm x 180mm 115mm x 115mm

45˚ Cuts 4″ 3

1

/

2

″ x 4″ 3

1

/

2

″ x 3

1

/

2

″

100mm 90mm x 100mm 90mm x 90mm

CAUTION