98

1. Remove the air compressor from the

carton.

2. Place the compressor on a secure,

stationary work surface and look it

over carefully.

Unpacking and Checking Contents

Do not operate unit if damaged

during shipping, handling or

use. Damage may result in

bursting and cause injury or

property damage.

!

WARNING

For your own safety, never

operate unit until all assembly

steps are complete and until

you have read and understood

the entire operator’s manual.

!

WARNING

To reduce the risk of injury, if

any parts are missing, do not

attempt to assemble the air

compressor until the missing

parts are obtained and installed

correctly.

!

WARNING

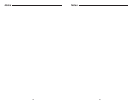

Figure 2

Getting to Know Your Air Compressor

1 Filter

2 Dipstick

3 Safety Valve

4 Regulator

5 Tank

Drain

6 Unloader

7 Beltguard

1. Air Filter.

The air filter keeps dirt and

debris from entering the compressor

pump.

2. Dipstick. The dipstick measures the

oil level in the compressor pump (See

Figure 3).

3. ASME Safety Valve. This valve auto-

matically releases air if the tank pres-

sure exceeds the preset maximum.

4. Regulator Knob. This knob controls

air pressure to an air operated tool or

paint spray gun. Turning the knob

clockwise increases air pressure at

the outlet. Turning counterclockwise

will lower air pressure at the outlet.

Fully counterclockwise will shut off

the flow of air completely (See Figure

4).

5. Tank Drain Valve. The tank drain

valve allows moisture to be removed

from the tank. Note that each tank

has its own tank drain valve.

6. Unloader. The unloader controls the

engine rpm. When loaded, the engine

will run at maximum operating speed

and air will enter the tank. When

unloaded, the engine will slow to an

idle and air will vent to atmosphere.

7. Belt Guard. The belt guard encloses

the pulleys and drive belt. It protects

the user from moving parts and

directs cooling air to the compressor

pump

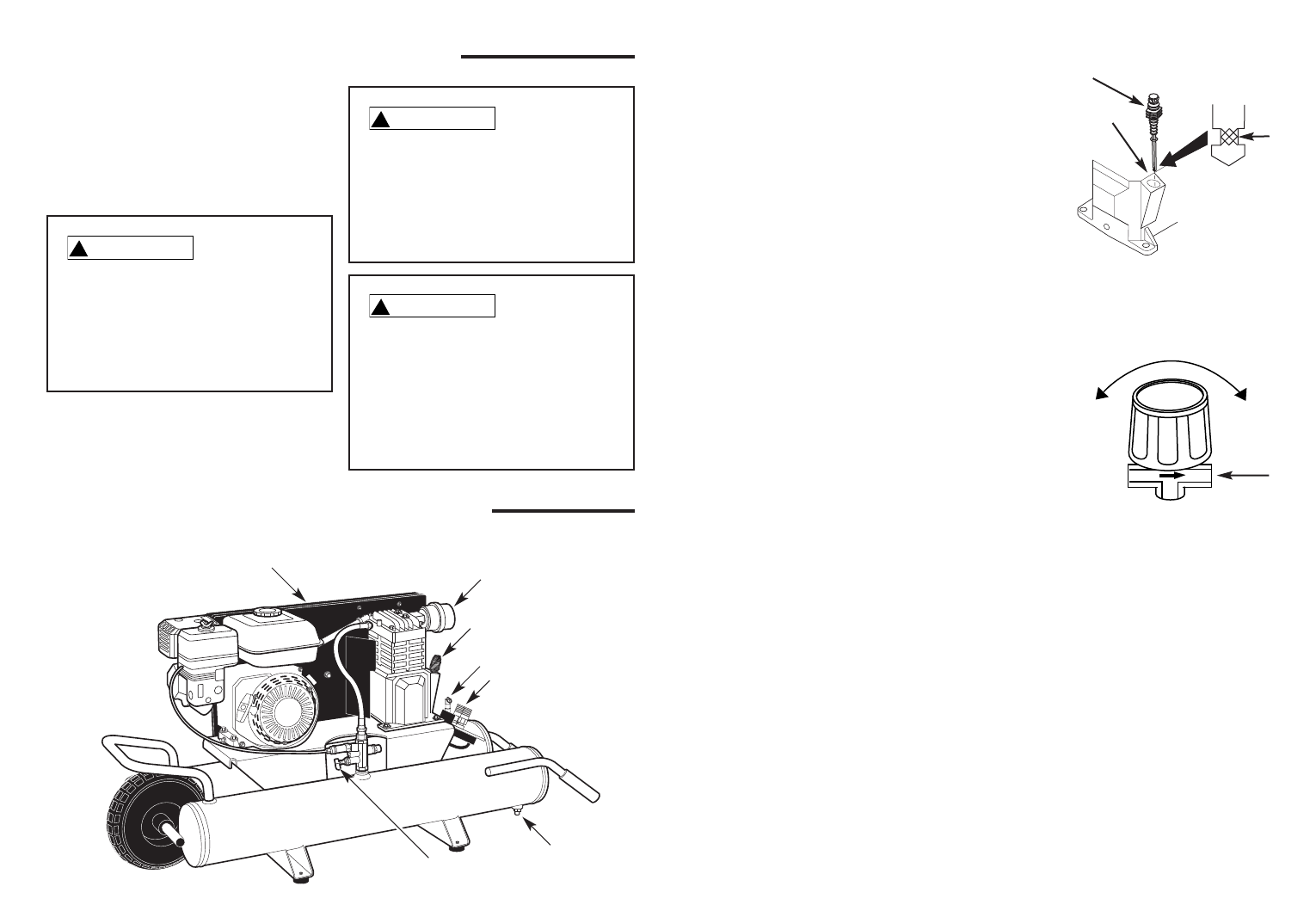

Dipstick

Add Oil

Fill

Line

Max

Low

Figure 3

Close

Open

Attach

Hose

Figure 4