All lubricated compressor pumps dis-

charge some condensed water and oil

with the compressed air. Install appropri-

ate water/oil removal equipment and con-

trols as necessary for the intended appli-

cation.

1110

Operating Your Air Compressor

Before starting the compressor,

thoroughly read all component

instruction manuals, especially

the engine manual.

NOTICE

Failure to install appropriate

water/oil removal equipment

may result in damage to

machinery or workpiece.

NOTICE

Drain liquid from tank daily.

NOTICE

Do not attach air tools to open

end of the hose until start-up is

completed and unit checks OK.

!

CAUTION

Moisture in Compressed Air

Moisture in compressed air will form into

droplets as it comes from an air compres-

sor pump. When humidity is high or when

a compressor is in continuous use for an

extended period of time, this moisture will

collect in the tank. When using a paint

spray or sandblast gun, this water will be

carried from the tank through the hose,

and out of the gun as droplets mixed with

the spray material.

IMPORTANT: This condensation will

cause water spots in a paint job, especial-

ly when spraying other than water based

paints. If sandblasting, it will cause the

sand to cake and clog the gun, rendering

it ineffective.

A filter in the air line, located as near to the

gun as possible, will help eliminate this

moisture.

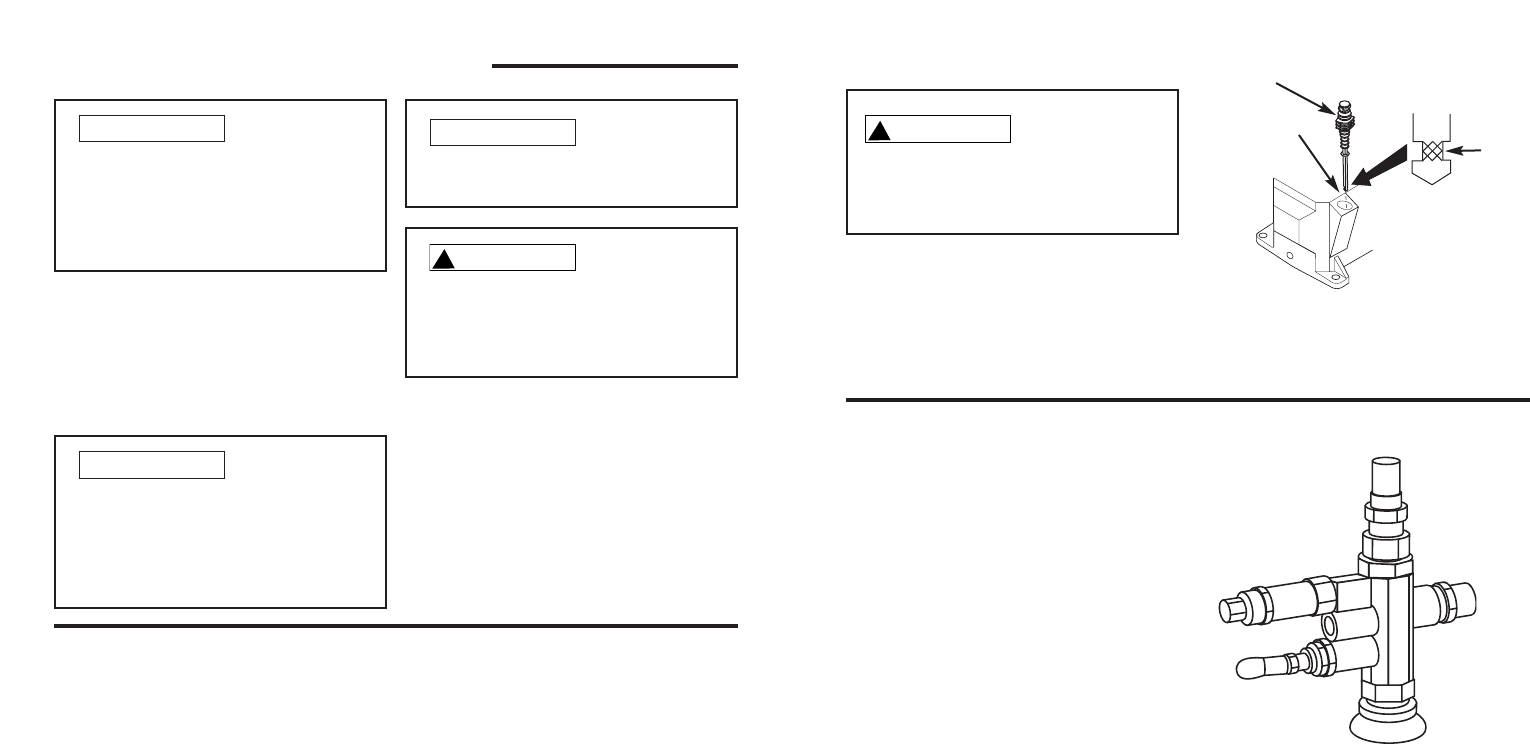

Remove the dipstick/ breather and fill

pump with 12 ounces of oil. Use single vis-

cosity, ISO 100 (SAE 30), non-detergent

compressor oil; or Mobil 1

®

5W30 or

10W30 synthetic oil may also be used.

Proper oil fill is illustrated in Figure 5.

THIS UNIT CONTAINS NO OIL!

Follow lubrication instructions

before operating compressor.

!

CAUTION

Lubrication

Dipstick

Add Oil

Fill

Line

Max

Low

Figure 5

1. Fill engine with oil and gasoline per

instructions furnished with engine.

2. Remove the compressor dipstick

breather and fill pump to the proper oil

level.

3. Turn regulator knob counterclockwise

to open air flow.

4. Turn manual unloader lever up to a

horizontal position to allow the com-

pressor pump to run without com-

pressing air. (See Figure 6).

Start-Up

Figure 6 - Manual Lever Unloaded Position