26

Alignments (continued)

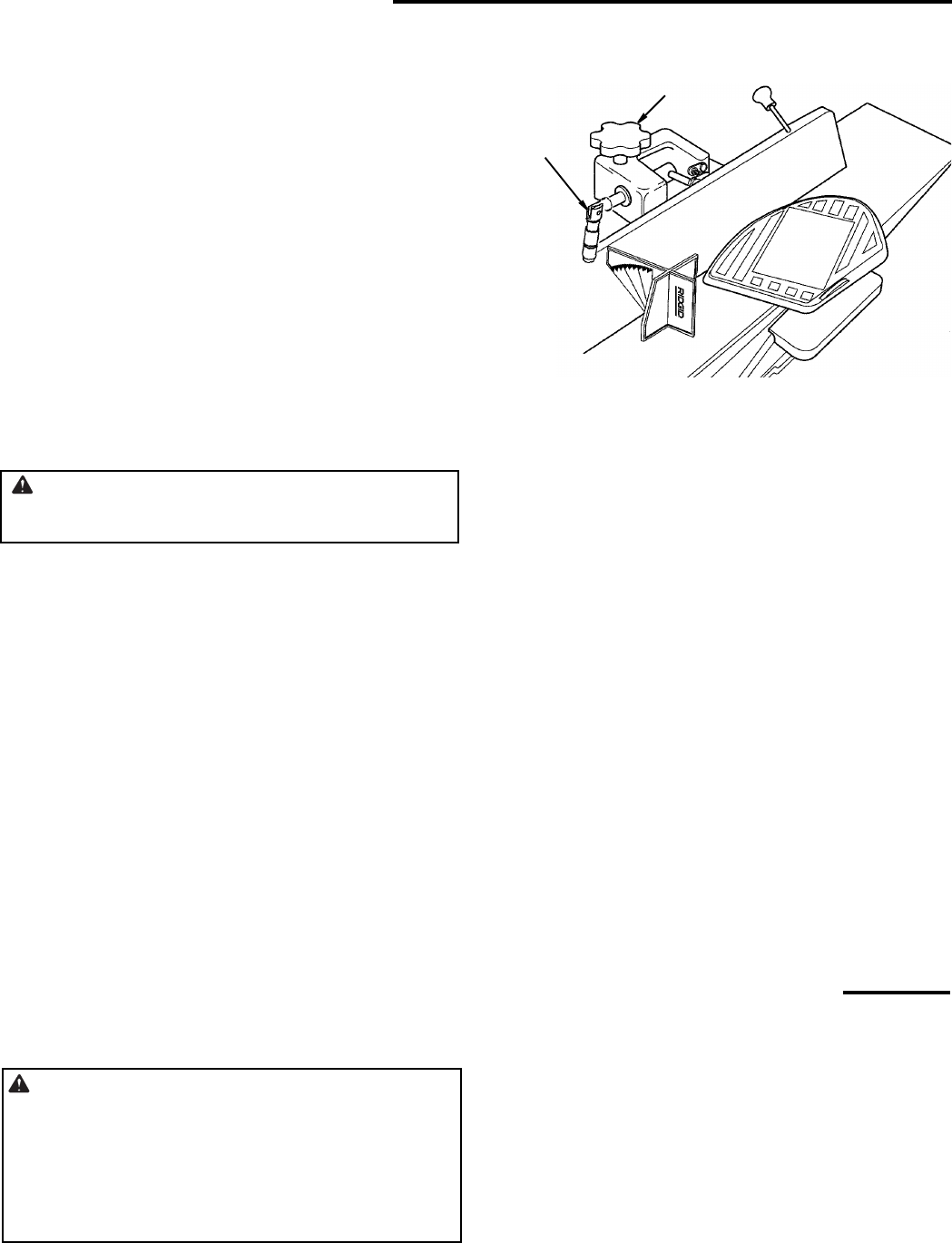

To set the fence to 90° simply pivot the fence slightly for-

ward of 90°, flip the 90° stop bar into place and pivot the

fence back until it contacts the 90° stop and lock into

place. The fence may need to be repositioned, using the

slide lock knob, over the cutterhead to provide adequate

cutting width.

The bevel stops are set at the factory, but may have

fallen out of alignment while in transit. To check for

squareness, place the included angle gauge on the out-

feed table and check fence while locked in the 90° posi-

tion.

To ensure accuracy and repeatability of the stops,

the bottom of the outfeed side of the fence should

rest firmly against the outfeed table and against the

head of the stop screw. Make sure that the infeed table

does not interfere with the accuracy of measurement.

The infeed table should be lowered to a depth of at least

1/16". Using the stops, check the fence for accuracy. If

the fence is not square to the outfeed table, at 90°, 45°

or 135° perform the following procedure:

WARNING: To reduce the risk of injury from acci-

dental start, make sure switch is “OFF” and plug is not

connected to power source outlet.

90° Bevel Stop Adjustment

1. Loosen bevel lock handle.

2. Make sure fence is tight against the stop and check the

angle using the included angle gauge.

3. Loosen the jam nut on the 90° stop screw.

4. Using the angle gauge, square the fence to the out-

feed table and tighten the bevel lock handle.

5. Turn the stop screw so it touches the stop. Tighten the

jam nut.

6. Loosen the bevel lock handle.

7. Move the fence to any angle and then return it to the

index. Check for accuracy with angle adjustment

gauge.

45° Bevel stop adjustment.

1. Loosen bevel lock handle.

2. Pivot the fence to the 45° stop and check with the

angle gauge.

3. If any adjustment is neccesary loosen the jam nut on

the 45° stop screw.

4. Set the fence to 45° using the angle gauge and lock

the bevel lock handle.

5. Turn the stop screw so it touches the stop. Tighten the

jam nut.

6. Loosen the bevel lock handle and move the fence to

any angle and back to 45°. Check for accuracy with

the angle gauge.

135° Bevel stop adjustment

1. Loosen bevel lock handle.

2. Flip the 90° stop bar out of the way and move the

fence until it contacts the 135° stop. Check with the

angle gauge.

3. If any adjustment is necessary loosen the jam nut on

the 135° stop screw.

4. Using the angle gauge, set the fence at 135° to the

outfeed table and tighten the bevel lock handle.

5. Turn the stop screw so it touches the stop. Tighten the

jam nut.

6. Loosen the bevel lock handle and move the fence to

any angle and back to 135°. Check for accuracy with

the angle gauge.

Safety Instructions for Basic Jointer/Planer Operation

Before Each Use

Inspect your jointer/planer.

WARNING: The 2-1/2 inch jointer/planer pulley and

the 3-1/2 inch motor pulley furnished will run the cutter

head at about 5000 RPM when used with a 3450 RPM

motor. Use of different types of pulleys or motors will

change this speed and could cause jamming, binding,

kickback, thrown blades or other dangers. To prevent

serious personal injury do not change original motor or

pulleys.

• To reduce the risk of injury from accidental starting,

always turn switch off, remove switch key and unplug

jointer/planer before installing or removing any blade,

accessory or attachment or making any adjustments.

• If any part is missing, bent or broken in any way, or any

electrical part does not work properly, turn the jointer/

planer off and unplug the jointer/planer.

• Replace damaged or missing parts before using the

jointer/planer again.

• Make sure the cutter head turns in the right direction.

The top should move toward the infeed table. Call an

Authorized Service Center for help if the cutter head

turns the wrong way.

• Keep Jointer/Planer interior, free of wood chips and

B

evel Lock

Handle

Fence Slide

Lock Knob