34

Troubleshooting Guide

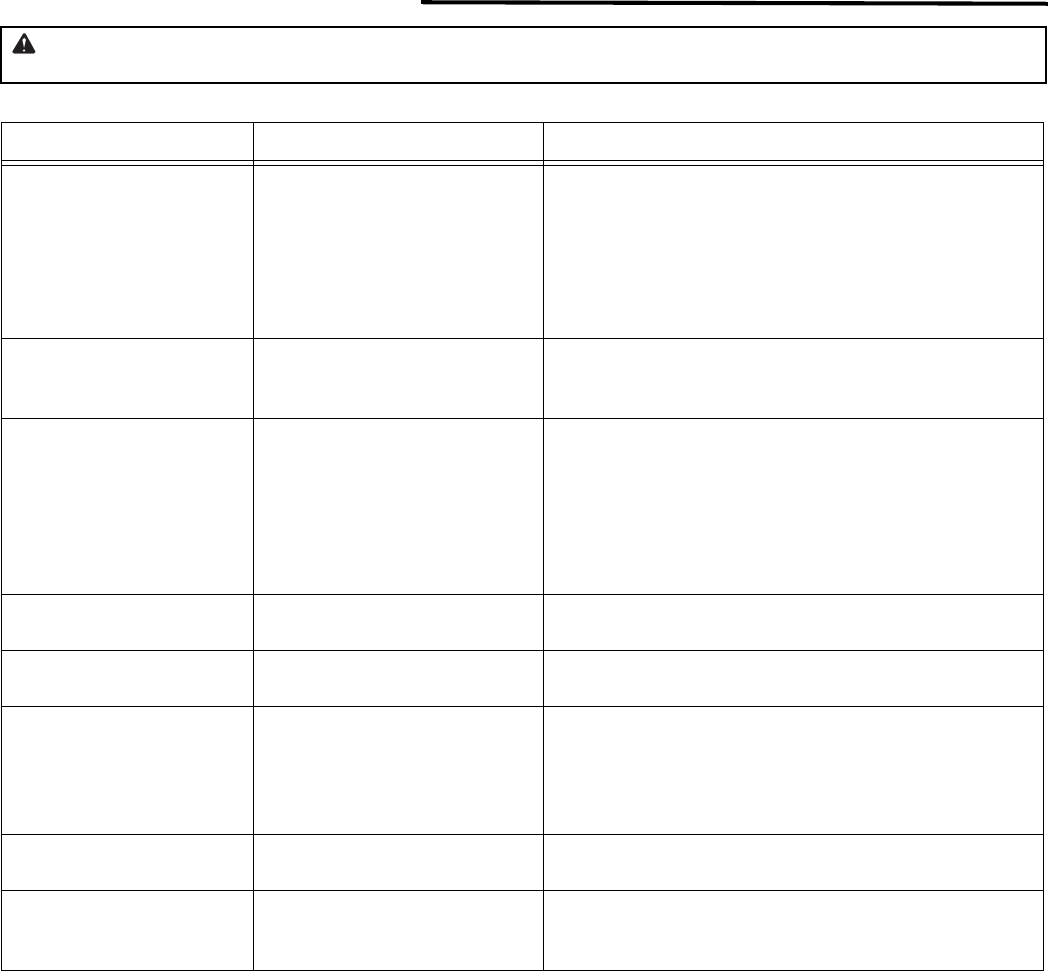

WARNING: For your own safety, turn switch “OFF” and remove plug from power source outlet before trouble-

shooting your jointer/planer.

General

Trouble Probable Cause Remedy

Motor will not run 1. Defective On-Off switch

Defective capacitor

Defective motor

2. Low line voltage

3. Belt tension too high

1. Consult an Authorized Service Center. Any attempt

to repair this electrical device may create a hazard

unless repair is done by a qualified service techni-

cian. Repair service is available at your nearest

Authorized Service Center.

2. See “Troubleshooting (Motor)” section.

3. Adjust belt tension

Wood strikes outfeed

table after passing over

cutterhead

Outfeed table improperly

adjusted above cutter blades

Readjust table, see “Outfeed Table Adjustment” sec-

tion

Ripples on planed sur-

face

Kickbacks

1. One blade set higher than

other

2. Feeding wood too fast

3. Cutting blades are set too

high above outfeed table,

or they are not leveled with

outfeed table

1. Readjust blades, see “Maintenance” section

2. Feed wood slower

3. Readjust blades, see “Maintenance” section

Planed surface not

straight

Outfeed table out of adjust-

ment

Readjust table, see “Outfeed Table Adjustment” sec-

tion

Excessive gouging at end

of cut

Outfeed table set too low Readjust table, see “Outfeed Table Adjustment” sec-

tion

45°, 90° and 135° cuts

inaccurate

1. Fence stops not adjusted

properly

2. Fence bottom not even with

outfeed table due to wood

chips under fence

1. Readjust fence stops, see “Alignment” section

2. Clean wood chips from underside of fence

Infeed or outfeed table

loose

1. Loose gib 1. Tighten gibs

Cutter guard does not

function properly

1. Return spring broken, or

spring needs adjustment

1. Consult an Authorized Service Center immediately

if broken.

2. Adjust spring.