36

®

BRUSH REPLACEMENT

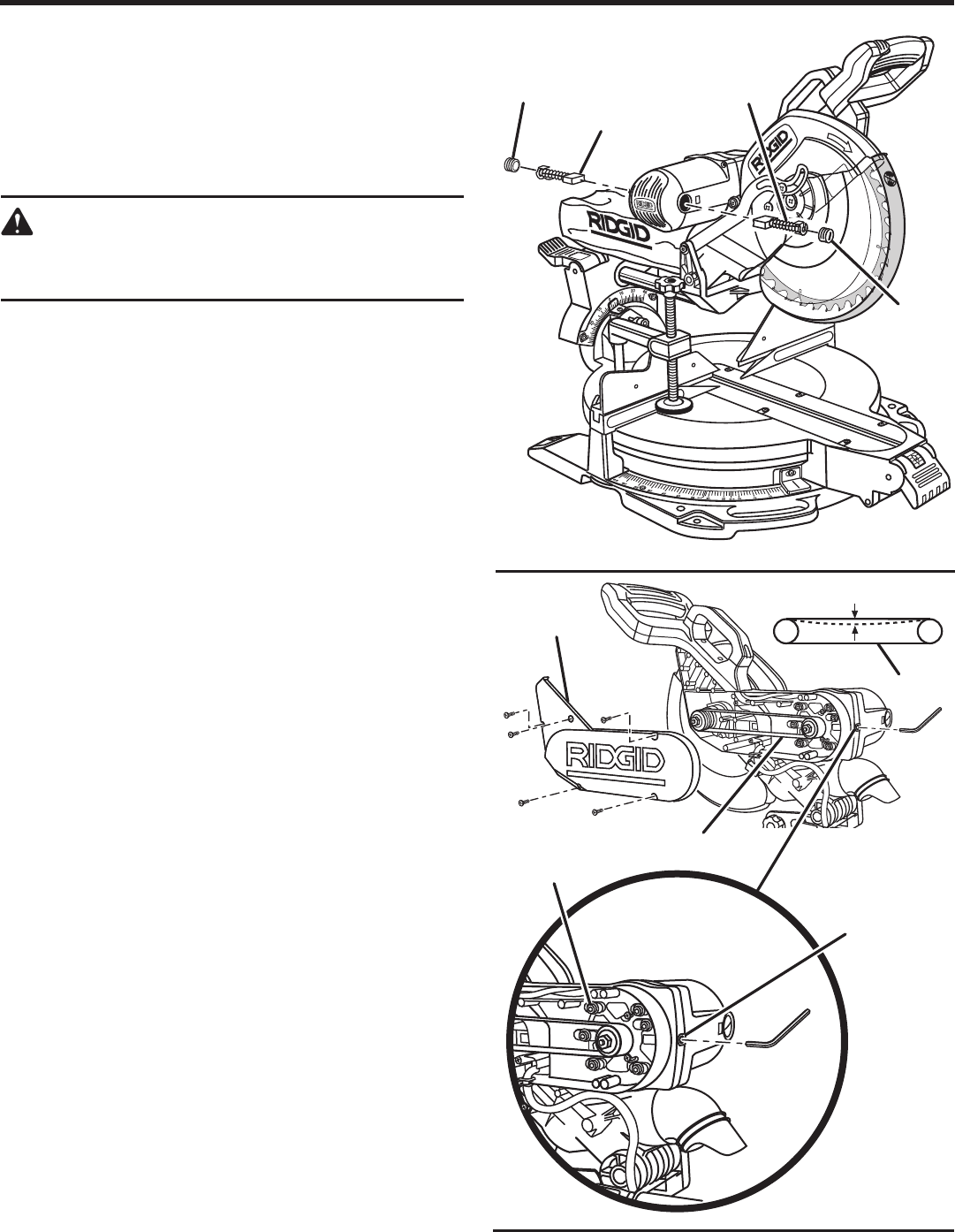

See Figure 50.

The saw has externally accessible brush assemblies that

should be periodically checked for wear.

Proceed as follows when replacement is required:

Unplug the saw.

WARNING:

Failure to unplug the saw could result in accidental

starting causing serious injury.

Remove brush cap with a screwdriver. Brush assembly is

spring loaded and will pop out when you remove brush

cap.

Remove brush assembly.

Check for wear. Replace both brushes when either has less

than 1/4 in. length of carbon remaining. Do not replace

one side without replacing the other.

Reassemble using new brush assemblies. Make sure

curvature of brush matches curvature of motor and that

brush moves freely in brush tube.

Make sure brush cap is oriented correctly (straight) and

replace.

Tighten brush cap securely. Do not overtighten.

MOTOR BELT TENSION

See Figure 51.

The motor belt tension was adjusted at the factory but should

still be checked periodically.

To check belt tension:

Using a phillips screwdriver, remove the screws holding

the belt cover. Lift off the cover.

Check belt tension by squeezing the belt. Using light

pressure, the belt should deflect approximately 1/4 in.

To adjust belt tension:

Loosen, but don’t remove, the six motor mount screws.

Increase the belt tension by turning the adjusting socket

head set screw clockwise. Decrease the belt tension by

turning the set screw counterclockwise.

NOTE: Excessive belt tension will cause the motor to fail

prematurely.

Securely tighten the six motor mount screws.

Replace the belt cover and tighten securely using

screws.

MAINTENANCE

BRUSH

CAP

Fig. 50

BRUSH

CAP

BRUSH

ASSEMBLY

BRUSH

ASSEMBLY

Fig. 51

ADJUSTING

SOCKET HEAD

SCREW

BELT COVER

MOTOR MOUNT

SCREWS

BELT

1/4 in.

BELT