9

Thermal Overload Protector

If thermal overload protector shuts motor

OFF frequently look for the following

causes.

1. Low voltage.

2. Wrong gauge wire.

3. Clogged air filter.

4. Lack of proper ventilation.

5. Unit is being used with an extension

cord.

See Troubleshooting Chart for corrective

action.

This compressor is equipped

with an automatic reset thermal

overload protector which will

shut off motor if it becomes

overheated.

!

CAUTION:

The motor must be allowed to

cool down before start-up is

possible. The motor will auto-

matically restart without warn-

ing if left plugged into electrical

outlet, and the motor is turned

on.

!

CAUTION:

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output

is measured by a pressure gauge on the

compressor

SCFM (Standard Cubic Feet per

Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume

delivered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The

combination of these figures determines

what size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Volts or Voltage

A measurement of the force of an electri-

cal current.

Amps or Amperage

A measure of the electrical force minus

the resistance on an electrical line.

Ridgid air compressors require 15 amps

for operation. Be sure the compressor

will operate on an electrical line with the

proper amps. If other appliances operate

on the same line, they will reduce the

available amps. If the amperage is not

adequate, the result will be blown fuses

or tripped circuits.

Regulator

A control that adjusts the line pressure to

the proper amount needed to operate

spray guns and air tools.

Tanks Pressure Gauge

Indicates tank pressure in psi.

Glossary of Terms

8

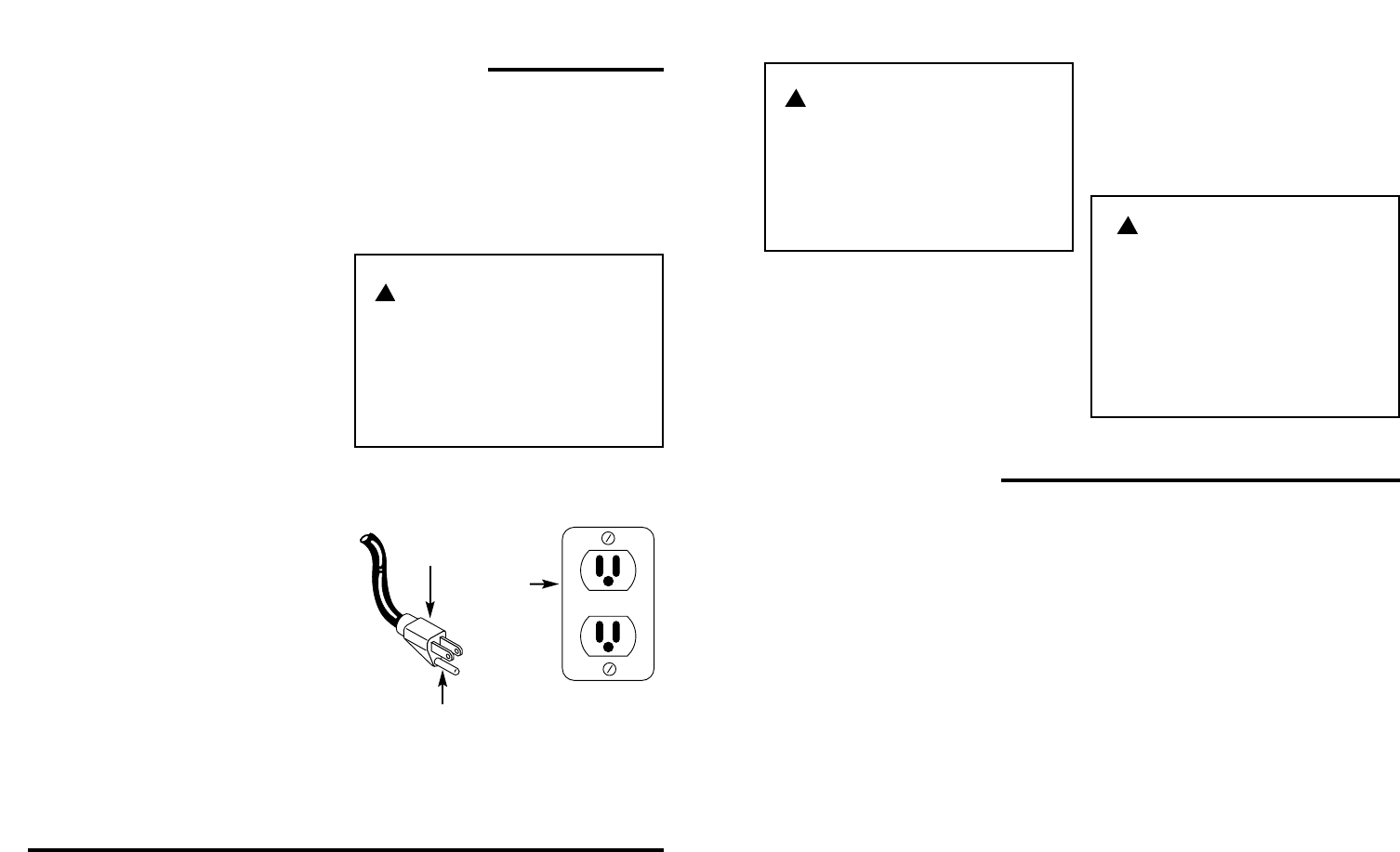

The plug supplied on your tool may not

fit into the outlet you are planning to use.

Your local electrical code may require

slightly different power cord plug connec-

tions. If these differences exist refer to

and make the proper adjustments per

you local code before your tool is

plugged in and turned on.

In the event of a malfunction or break-

down, grounding provides a path of least

resistance for electrical current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accor-

dance with all local codes and ordi-

nances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

If the grounding instructions are not com-

pletely understood, or if you are in doubt

as to whether the tool is properly ground-

ed check with a qualified electrician or

service personnel.

Motor Specifications and

Electrical Requirements (continued)

110-120 volt, 60Hz Tool Information

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

!

WARNING:

TEST

RESET

Grounding Prong

3-Prong Plug

Properly

Grounded

3-Prong

Outlet

Extension Cords

1. The air compressor should be located

where it can be directly plugged into

an outlet. An extension cord should

not be used with this unit.

2. To avoid loss of power and overheat-

ing, additional air hose must be used

to reach work area instead of exten-

sion cords.