19

Operation Daily Weekly

Drain Tanks ●

Check Air Filter ●

Check Safety Valve ●

Blow Dirt From Inside Motor ●

Maintenance Schedule

1. When not in use, compressor should be

stored in a cool dry place.

2. Tanks should be drained of moisture.

3. Hose should be disconnected and hung

open ends down to allow any moisture

to drain.

Storage

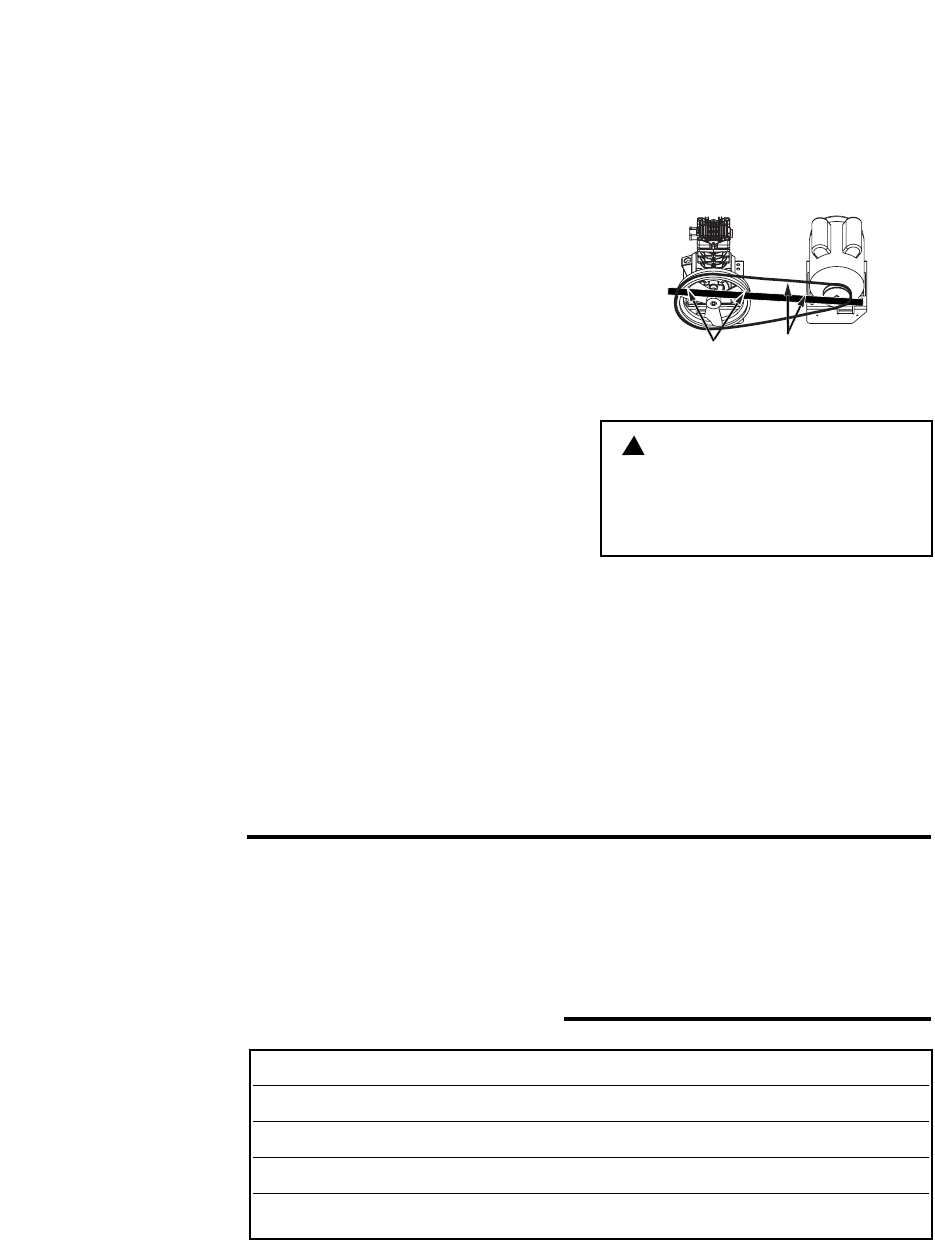

2. With a marker, mark the edge where

the motor meets the base (the edge

farthest away from the pump).

3. Remove the belt guard bolt and nut.

4. Remove the front belt guard cover.

5. Loosen the four motor mounting

bolts.

6. The belt tension will pull the motor

toward the pump. Remove the belt

from the unit and set it on the ground.

7. Using the reference mark made in

step 1, move the motor approximately

1/4" past the mark (moving it away

from the pump).

8. Use a straight edge to make sure the

motor pulley is in line with the pump

flywheel. Tighten down the two motor

bolts furthest from the pump.

9. Put the belt on the motor pulley and

carefully roll it over the pump fly-

wheel. Do this by starting the other

end of the belt over the top of the

pump flywheel and turning the fly-

wheel counterclockwise.

Touch Rim in Two

Places

Straight Edge

Parallel With Belt

10. Check belt tension. If still too loose,

loosen the front two motor bolts and

repeat steps 4-6. (When doing so,

move motor an additional 1/4" away

from pump).

11. When belt tension is good, tighten the

other two motor bolts.

12. Install the front belt guard cover.

13. Install and tighten the belt guard bolt

and nut.

When installing belt, use

caution to avoid injury to

fingers or hands.

!

CAUTION: