23

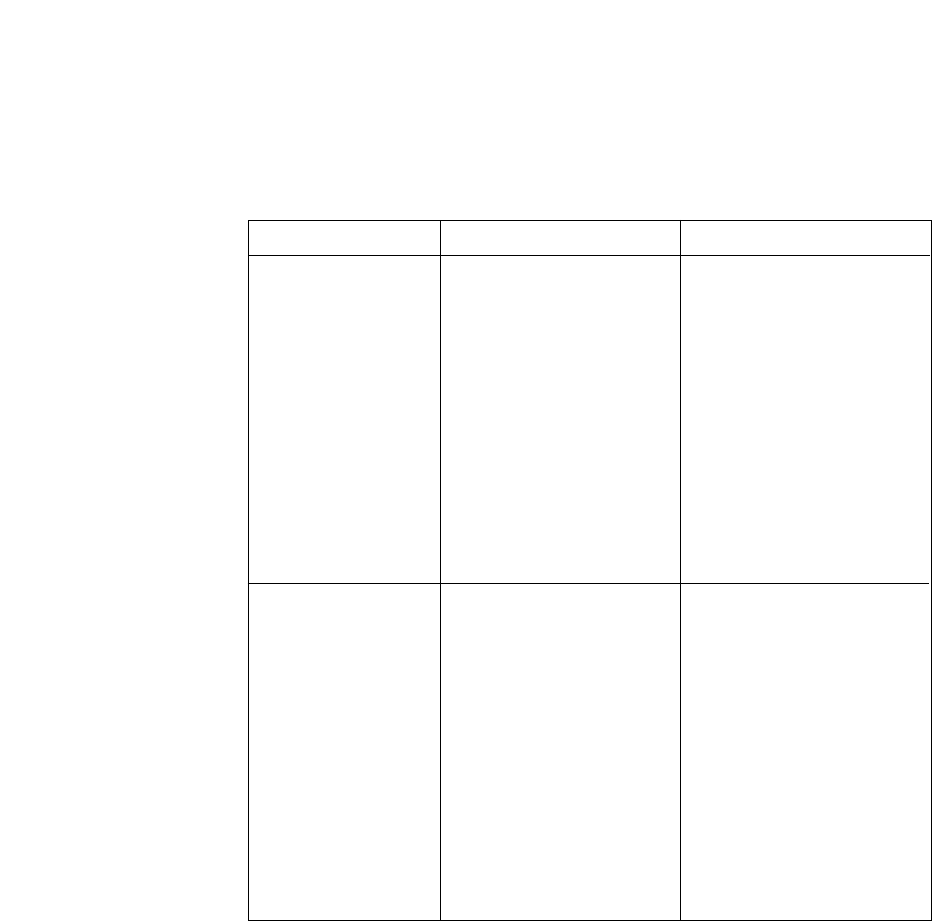

TROUBLE PROBABLE CAUSE REMEDY

Excessive belt wear

Oil in the discharge

air

1. Pulley out of alignment

2. Belt too loose or too tight

3. Belt slipping

4. Pulley wobbles

1. Worn piston rings

2. Compressor air intake

restricted

3. Restricted breather

4. Excessive oil in compres-

sor

5. Wrong oil viscosity

6. Connecting rod out of

alignment

1. Realign motor pulley with

compressor pulley

2. Adjust tension (See Drive

Belt Section)

3. Adjust tension or replace

belt (See Drive Belt

Section)

4. Check for worn crankshaft,

keyway or pulley bore

resulting from running the

compressor or motor with

loose pulleys. Check for

bent pulleys or bent crank-

shaft

1. Replace with new rings

2. Clean filter. Check for other

restrictions in the intake

system

3. Clean and check breather

for free operation

4. Drain down to full level

5. Use SAE 30 (ISO 100)

non-detergent compressor

oil, Mobil 1 5W30 or Mobil

1 10W30 (See page 14).

6. Replace rod