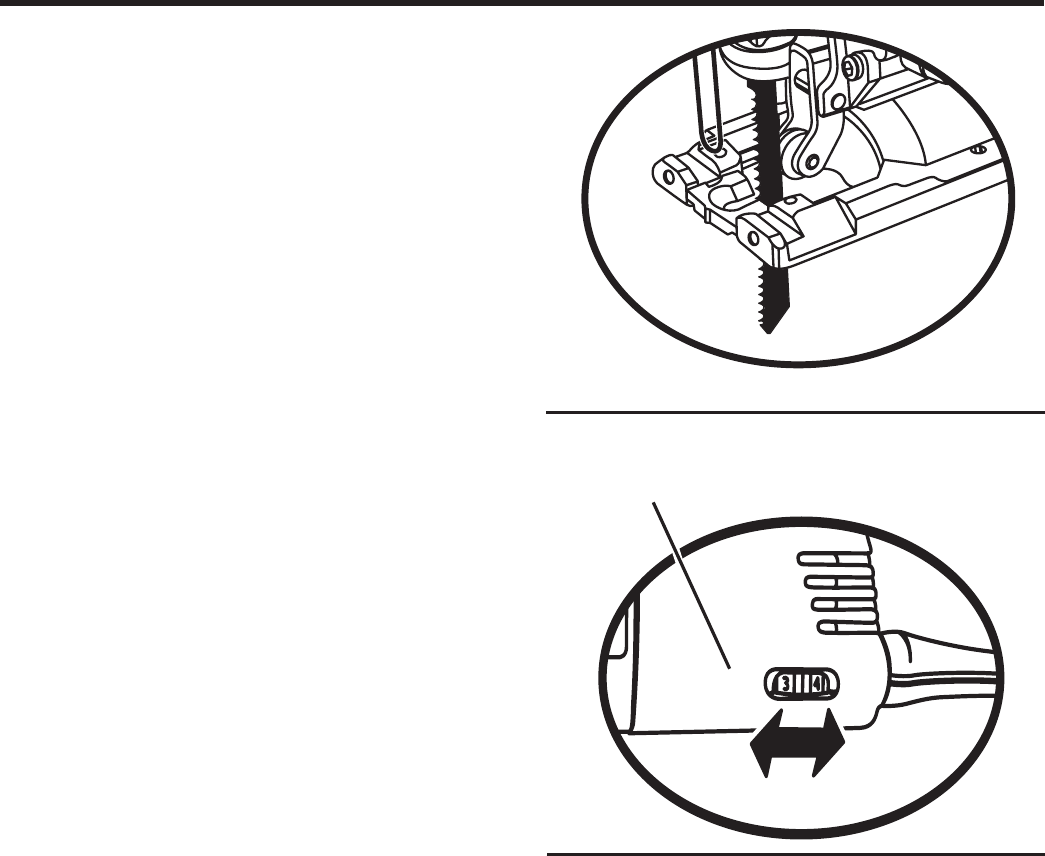

10

11

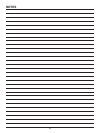

Fig. 5

OPERATION

Splinter-Free Cutting

See Figure 4.

This saw has a splinter guard to permit splinter-free cutting.

It is especially useful when cutting plywood. This feature

should only be used when making straight cuts or circle

cuts. It is not for bevel cutting or plunge cutting.

Note: The non-orbital setting also helps reduce splintering

when cutting plywood.

Variable Speed

See Figure 5.

The saw has a variable speed control selector designed to

allow operator control and adjustment of speed and power

limits. The speed and power of your saw can be increased

or decreased by rotating the variable speed control selector

in the direction of the arrows shown in gure 5.

Note: Hold the saw in normal operating position and turn

the variable speed control selector to the higher numbers

to increase speed and power. Turn to the lower numbers

to decrease speed and power.

If you desire to lock the switch on at a given speed, depress

the switch trigger, push in and hold the lock-on button, and

release the switch trigger. Next, adjust the variable speed

control selector until the desired speed is reached.

Note: If you desire not to use the variable speed control

selector, turn it to Setting 6. This will allow the speed of

the saw to be controlled by the amount of switch trigger

depression.

Avoid running your saw at low speeds for extended periods

of time. Running at low speeds under constant usage may

cause your saw to become overheated. If this occurs, cool

your saw by running it without a load and at full speed.

The following guidelines may be used in determining cor-

rect speed for various applications:

LOW speed (Settings 1 and 2) is ideal when minimum speed

and power is required, for example, starting cuts.

MEDIUM speed (Settings 3 and 4) is suitable for cutting

hard metals, plastics, and laminates.

HIGH speed (Settings 5 and 6) produces best results when

maximum power is required, for example, cutting wood.

Soft metals such as aluminum, brass, and copper may

also require high speeds.

VARIABLE SPEED

CONTROL SELECTOR

Fig.4