13

MAINTENANCE

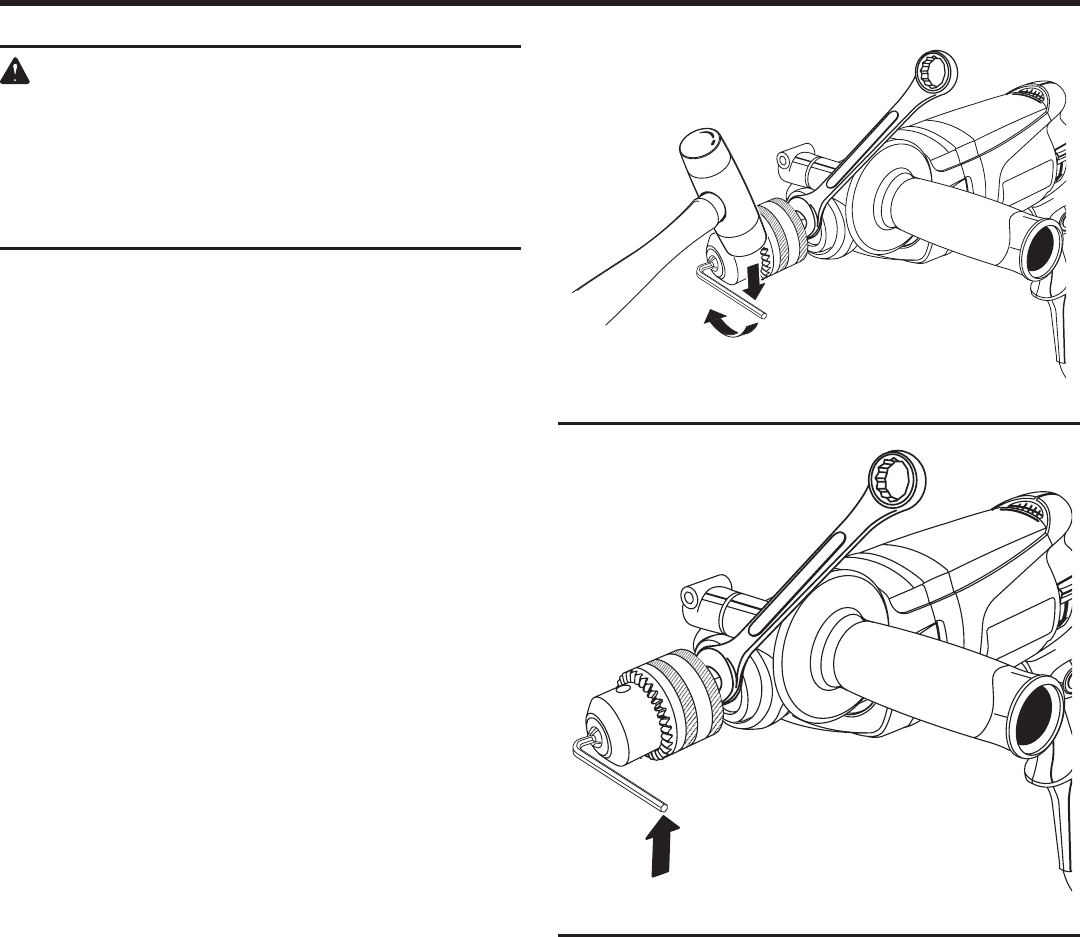

Fig. 9

CHUCK REMOVAL

See Figure 9 - 10.

The chuck must be removed in order to use some

accessories. To remove:

n Unplug the drill.

n Open chuck jaws using the provided chuck key.

n Insert a 5/16 inch (8 mm) or larger hex key wrench into the

chuck of the drill and tighten the chuck jaws securely.

n Place an open-end wrench directly behind the chuck;

hold to prevent movement of the spindle.

n Tap the hex key wrench sharply with a mallet in a

clockwise direction. This will loosen the screw in the

chuck for easy removal.

n Open chuck jaws and remove hex key. Remove the chuck

screw by turning it in a clockwise direction.

NOTE: The screw has left hand threads.

n Insert hex key wrench in the chuck and tighten chuck

jaws securely.

n Tap sharply with a mallet in a counterclockwise direction.

This will loosen chuck on the spindle. It can now be

unscrewed by hand.

TO RETIGHTEN A LOOSE CHUCK

See Figure 9.

The chuck may become loose on the spindle and develop a

wobble when using the drill. Periodically check chuck screw

for tightness. A loose screw may cause the chuck jaws to

bind and prevent them from closing. To tighten, follow these

steps:

n Unplug the drill.

n Open the chuck jaws.

n Insert the hex key wrench into the chuck and tighten the

chuck jaws securely. Tap the hex key sharply with a mallet

in a clockwise direction. This will tighten the chuck on the

spindle.

n Place an open-end wrench directly behind the chuck;

hold to prevent movement of the spindle.

n Open the chuck jaws and remove the hex key wrench.

n Tighten the chuck screw.

NOTE: The chuck screw has left hand threads.

WARNING:

This tool should never be connected to a power

supply when you are assembling parts, making

adjustments, cleaning, performing maintenance, or

when the tool is not in use. Disconnecting the tool

will prevent accidental starting that could cause

serious injury.

Fig. 10