Page 7

FEATURES

WARNING:

Your detail biscuit joiner should never be connected to power supply when you are assembling parts, making

adjustments, assembling or removing blades, cleaning or when not in use. Disconnecting your detail biscuit joiner will

prevent accidental starting that could cause serious personal injury.

Fig. 1

Your detail biscuit joiner has been designed for making fast,

accurate, and simple plunge cuts in wood, etc. so that

biscuits can be used to join two or more boards together.

When used properly and only for what it is intended, this

versatile tool will give you years of trouble-free performance.

It is professionally engineered, but its ease of operation

allows the amateur to produce beautiful and precise work.

SWITCH

To turn your biscuit joiner ON, depress the switch trigger.

Release switch trigger to turn your biscuit joiner OFF.

MOTOR

Your biscuit joiner has a powerful motor with sufficient power

to handle tough cutting jobs. It develops a no load speed of

19,000 RPM.

BLADE

Your biscuit joiner has a 1-1/2 in. (38 mm) 6 tooth blade for

cutting biscuit slots.

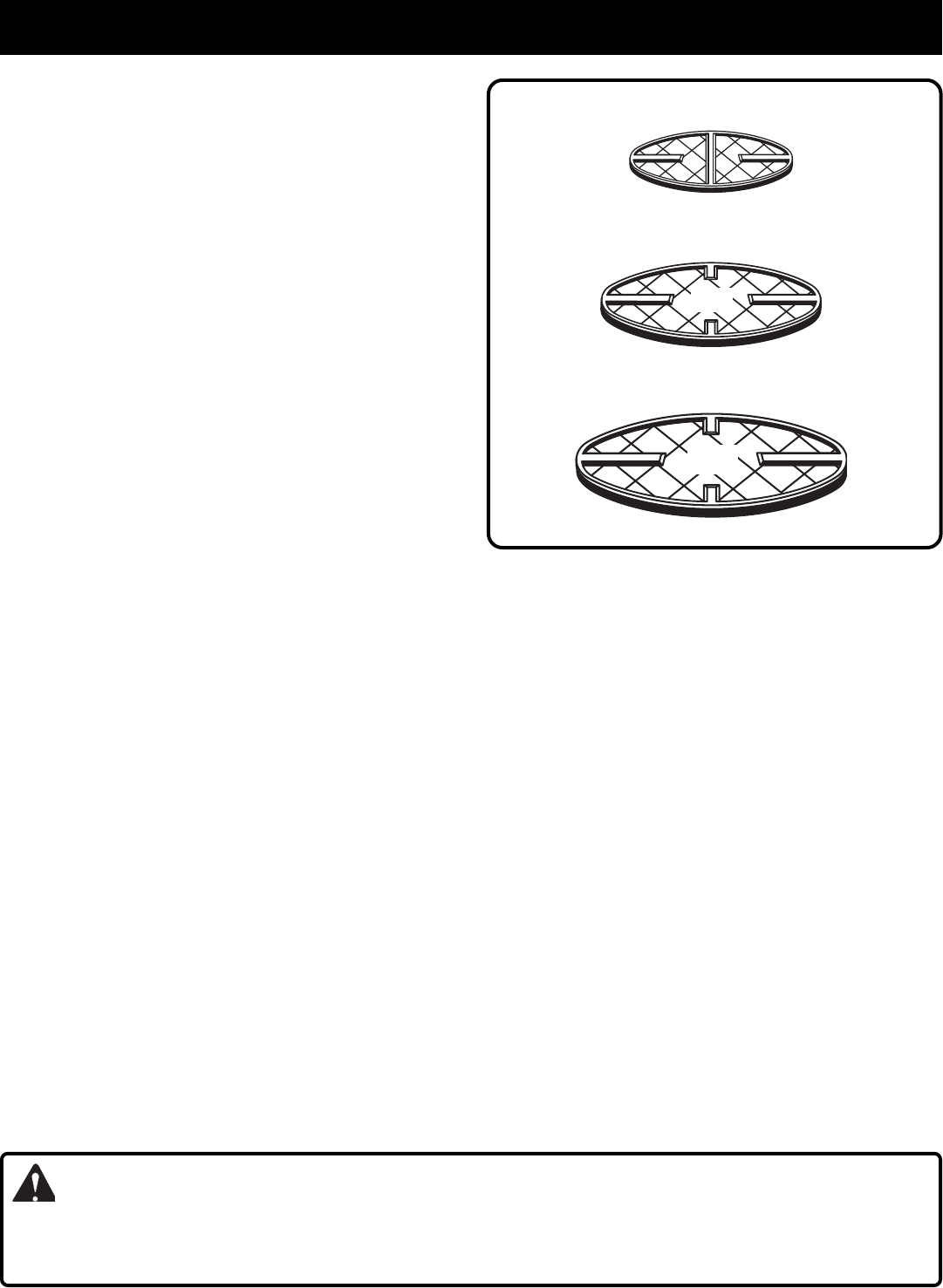

BISCUITS

See Figure 1.

Biscuits are available in three standard sizes:

#R1 (7/32 in. x 5/8 in.)

#R2 (9/32 in. x 3/4 in.)

#R3 (1/2 in. x 1 in.)

NOTE: Store biscuits in a dry place because they swell

rapidly upon contact with water-based woodworking glues.

REVERSIBLE FENCE FOR 45° AND 90° CUTS

Your biscuit joiner has a reversible fence. By loosening the

height adjustment knobs, the fence can be removed through

key hole slots. Once removed, it can be rotated 180° changing

the angle of cut from 90° to 45° or vice versa. The height of

the fence at 90° can be set between 0 to 3/4 in. from the

center of the blade. The height of the fence at 45° can be set

between 5/16 in. to 13/16 in. from the center of the blade.

The fence should always be used to guide and balance your

biscuit joiner, providing ease of operation and maintaining

safe control.

NONSKID BACKING PAD

The fence on your biscuit joiner is padded with a nonskid

backing pad to hold it stationary against the workpiece. It

helps prevent skidding when making cuts. It also prevents

marring of the workpiece from biscuit joiner when cutting.

INDICATOR MARKS

Centerline and line of cut indicator marks have been provided

on your biscuit joiner.

See Figure 2.

APPLICATIONS

(Use only for the purpose listed below)

■ Cutting precise mating oval slots in hardwood, softwood,

plywood, particle board, etc. for spline joinery applications.

ELECTRICAL CONNECTION

Your biscuit joiner has a precision built electric motor. It

should be connected to a power supply that is 120 volts,

60 Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If your biscuit joiner does not operate when plugged into an

outlet, double-check the power supply.

DEPTH ADJUSTMENT KNOB

A spring loaded depth adjustment knob makes it possible to

make proper settings for three standard size biscuits. Fine

adjustments to the cutting depth can be made with a knurled

adjustment knob and jam nut located behind the depth

adjustment knob. Once the correct depth setting has been

made for one biscuit size, the other two depth settings will be

automatically set.

3

2

#R1 = 7/32 in. x 5/8 in.

#R2 = 9/32 in. x 3/4 in.

#R3 = 1/2 in. x 1 in.

O

A

b

p