13

1

2

D

r

l

l

i

P

r

e

s

s

O

N

R

E

M

O

V

E

T

O

L

O

C

K

ADJUSTMENTS

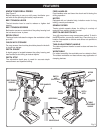

Fig. 14

BELT TENSION

LEVER

CHANGING SPEEDS

See Figure 14.

WARNING:

Before performing any adjustment, make sure the drill

press is unplugged from the power supply and the switch

is in the OFF position. Failure to heed this warning could

result in serious personal injury.

The spindle speed is determined by the location of the belts

on the pulleys inside the head assembly. The speed chart

located on the cover inside the head assembly shows the

recommended speed and pulley configuration for each drilling

operation. To change the pulley configuration, refer to figure

14 and proceed as follows:

■ Loosen the two belt tension screws located on each side of

the head assembly.

■ Push the belt tension lever to release belt tension and to

loosen the belts.

OPERATION

WARNING:

Before attempting to use your drill press familiarize

yourself with all operating features and safety

requirements.

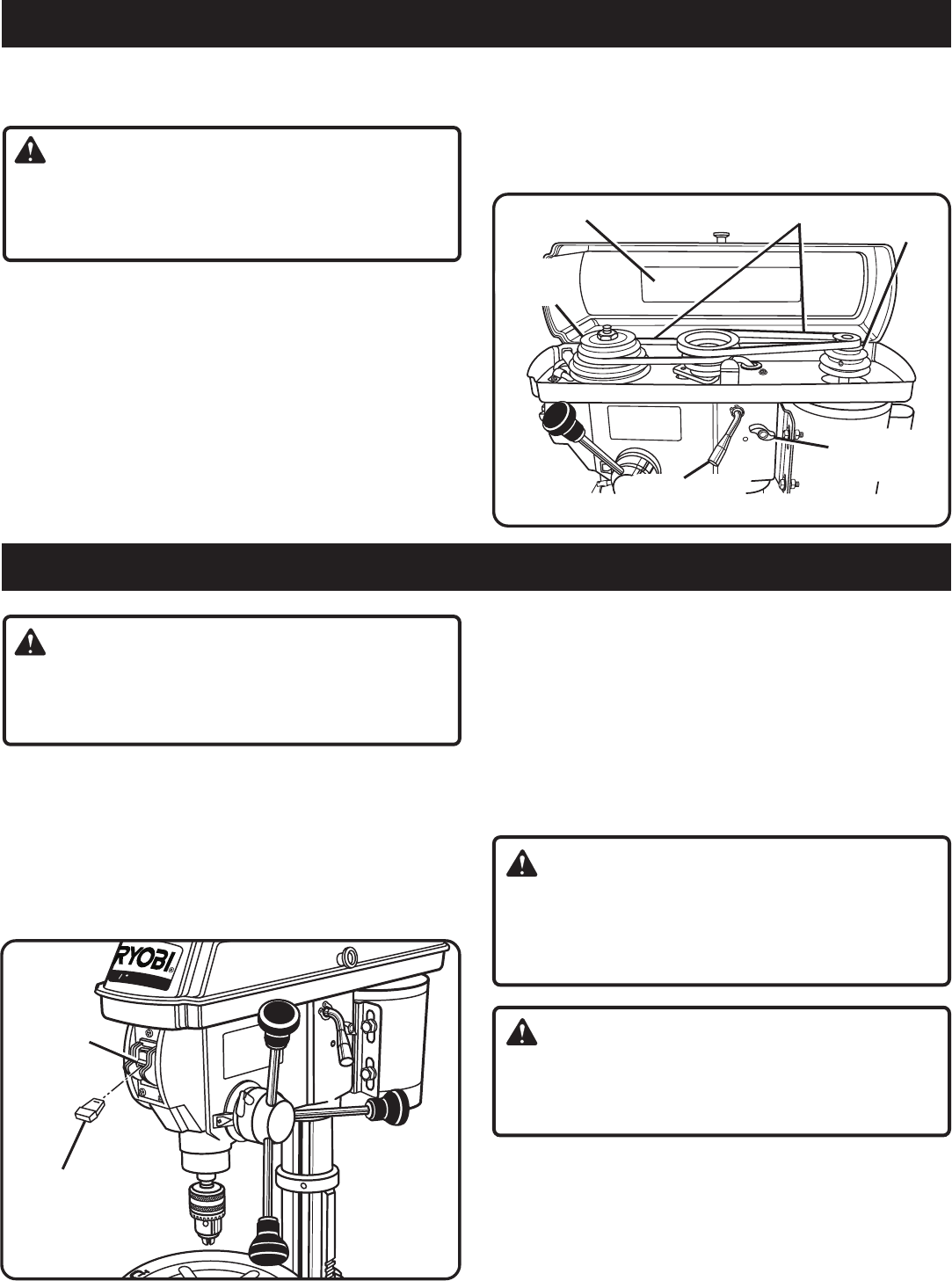

LOCKING THE SWITCH

See Figure 15.

■ Place the switch in the OFF position.

■ Wait until the drill press has come to a full and complete

stop.

■ Remove the switch key from the switch assembly. Store

key in safe place.

SWITCH KEY

SWITCH

Fig. 15

SELF-EJECTING CHUCK KEY

The self-ejecting chuck key ensures that the chuck key is

removed from the chuck BEFORE the drill press is turned

on.

In order to loosen or tighten the chuck using the chuck key,

push the key into the chuck hole. Rotate the key clockwise

to tighten the chuck, counterclockwise to loosen the chuck.

When you are finished with the chuck key, always replace it

in the chuck key storage located on the head assembly.

WARNING:

Use only the self-ejecting chuck key provided. Always

remove chuck key and store in the on-board chuck key

storage. Failure to heed this warning could result in

serious personal injury.

WARNING:

Always remember to remove the chuck key from the table

surface before turning on the drill press. Failure to heed

this warning could result in serious personal injury.

TABLE ROTATION

When drilling large objects it may be necessary to swing the

table out of the way. Simply loosen the table lock lever, rotate

the table, and retighten table lock lever.

Note: When using the base as a work surface, the workpiece

must be clamped securely to the base.

BELT TENSION

SCREWS

MOTOR

PULLEY

SPEED CHART

BELTS

SPINDLE

PULLEY

■ Open the head assembly cover and reposition the belt

according to the speed chart. Close the cover.

■ Push the belt tension lever firmly back into position

assuring drive belt is tight. While holding tension on the

motor, retighten the two belt tension knobs securely.