15

OPERATION

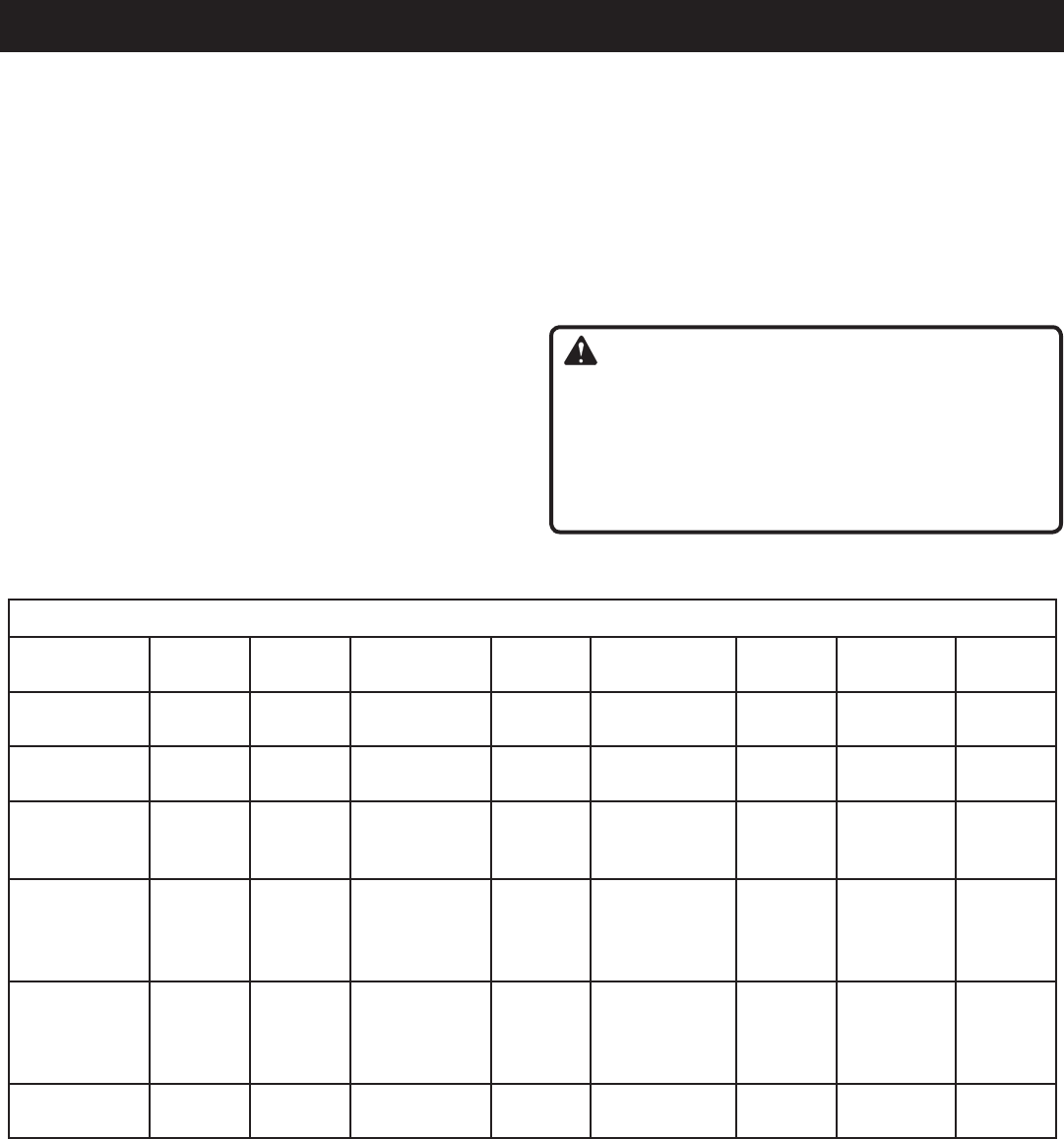

To determine the optimum operational speed for different

materials and accessories, refer to the Speed Dial Settings

table. Look this table over and become familiar with it.

The best way to determine the correct speed for work on

any material is to practice for a few minutes on a piece of

scrap, even after referring to the table. You can quickly

learn that a slower or faster speed is more effective just by

observing what happens when you make a pass or two at

different speeds.

When working with a scrap piece of plastic, start at a slow

rate of speed and increase the speed until you observe

whether the plastic is melting at the point of contact; reduce

the speed slightly to get optimum working speed without

melting the workpiece.

SPEED DIAL SETTINGS

Type of

Accessory

Soft

Wood

Hard

Wood

Laminates

Plastics

Steel

Aluminum,

Brass, Etc.

Shell/

Stone

Ceramic

Glass

Cut-off

Discs

25-30 18-30 10-18 10-18 10-30 — — —

Engraving

Cutter

25-30 25-30 15-25 25-30 10-18 — — —

Rubber

Polishing

Points

— — — 10-15 10-15 — — —

Aluminum

Oxide

Grinding

Stones

— — 10-15 — 10-18 10-18 — —

Silicon

Carbide

Grinding

Stone

— — — — 10-15 10-15 12-15 10-15

Wire

Wheels

10-15 10-15 — 10-15 10-15 10-15 — —

NOTE:

Plastic and materials that melt at low temperatures should

be cut at low speeds.

Soft wood should be cut at high speed.

Aluminum, tin, and copper, lead, and zinc alloys may be

cut at any speed, depending on the type of cutting being

done. Use paraffin or other suitable lubricant on the cutter

to prevent the cut material from adhering to the cutter

teeth.

WARNING:

Wire brushes must never be operated at speeds higher

than 15,000 RPM. Wire brushes must run at least one

minute before use. During this period, no one should

stand in front of or in line with the rotating brush. Failure

to heed this warning could result in serious personal

injury.