17

OPERATION

TELESCOPING TOOL HANGER WITH CLAMP

ON BASE

See Figure 11.

The telescoping tool hanger provides a convenient place to

hang the rotary tool while the flex shaft is in use.

To clamp the base to a worktable:

Turn the clamp screw counterclockwise to open the

clamping area.

Place clamp over edge of worktable.

Turn the clamp screw clockwise until the clamp is

secure.

To attach the tool hanger to the base:

Turn the lower part of the tool hanger clockwise to

unlock.

Pull the tool hanger up to lengthen or push the tool hanger

down to shorten its height.

Turn the lower part of the tool hanger counterclockwise

to lock into place.

Screw the tool hanger into the top of the clamp.

NOTE: When using the flex shaft, hang the rotary tool from

the tool hanger hook using the hook located on the back of

the rotary tool.

CAUTION:

To prevent damage to the spindle or spindle lock, always

allow motor to come to a complete stop before engaging

the spindle lock.

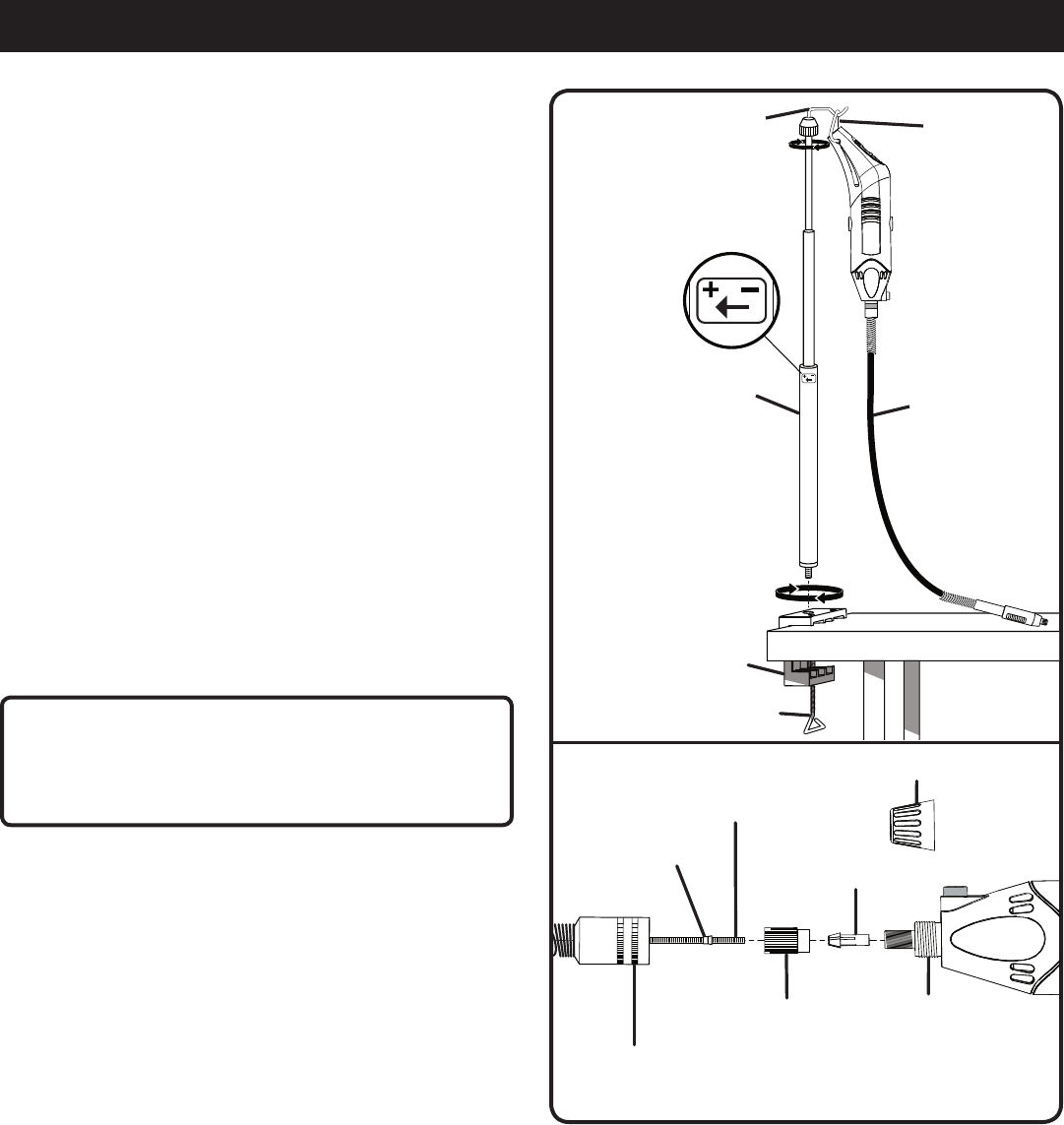

OPERATING THE FLEX SHAFT

See Figures 12 - 14.

The 1/8 in. collet must be inserted into the rotary tool before

the flex shaft can be installed.

To install the flex shaft:

Unplug the rotary tool.

Loosen collet sleeve by turning counterclockwise and

remove.

Press and hold the spindle lock, and rotate the shaft by

hand until the spindle lock engages the shaft, preventing

further rotation.

With the spindle lock engaged, use the collet wrench to

loosen the collet nut, if necessary.

Remove collet nut and collet.

Insert the 1/8 in. collet.

Replace the collet nut and tighten loosely.

Fig. 12

Fig. 11

CUP END OF

FLEX SHAFT

COLLET SLEEVE

CLAMP SCREW

CLAMP-ON BASE

TOOL HANGER

FLEX SHAFT

ROTARY TOOL

HOOK

TOOL HANGER

HOOK

COLLET

NUT

DRIVE

SHAFT

1/8 in.

COLLET

ROTARY

TOOL HEAD

COLLAR

Insert drive shaft into collet nut until the collar meets the

collet nut.

Tighten the collet nut completely, keeping collar in contact

with collet nut.

Insert cup end of flex shaft onto rotary tool head. Turn

clockwise to tighten.