Page 17

45˚

30˚

15˚

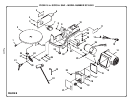

CHOICE OF BLADE AND SPEED

The scroll saw accepts a wide variety of blade widths and thicknesses for cutting wood and other fibrous materials. Your saw

uses 5 inch long blades of either the pin end or the plain end style. The blade width and thickness and the number of teeth

per inch to use are determined by the type of material and the size of the radius being cut. A full selection of scroll saw blades

are available at your local Ryobi dealer.

Note: As a general rule, always select narrow blades for intricate curve cutting, and wide blades for straight and large curve

cutting.

BEFORE EACH USE:

■ INSPECT YOUR SAW. Disconnect the saw. To avoid

injury from accidental starting, turn the switch OFF and

unplug the saw before changing the setup or removing

covers, guards, or blade.

■ INSPECT YOUR WORKPIECE. Make sure there are no

nails or foreign objects in the workpiece to be cut.

■ USE EXTRA CAUTION WITH LARGE, VERY SMALL,

OR AWKWARD WORKPIECES.

• Never use this tool to cut pieces too small to hold by

hand.

Speed or

Teeth/Inch Width Thickness Strokes Per Material Cut

Minute

• Always use extra supports (tables, saw horses, blocks,

etc.) for any workpiece large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table

extension, or as additional support for a workpiece or to

help feed, support, or pull the workpiece.

• When cutting an irregularly shaped workpiece, plan

your work so it will not pinch the blade. A piece of

molding, for example, must lay flat or be held by a fixture

or jig that will not let it twist, rock, or slip while being cut.

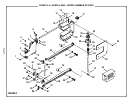

Fig. 21

STACK CUTTING

See Figure 21.

After becoming well acquainted with your saw through

practice and experience, you may wish to try stack cutting.

Stack cutting may be used when several identical shapes

need to be cut. Several pieces of wood may be stacked on

top and secured to each other before cutting. The wood

pieces may be joined together by placing double sided tape

between each piece or by wrapping masking tape around the

corners or ends of the stacked wood. You must attach the

stacked pieces of wood to each other so they will move on the

table as a single piece of material.

WARNING:

To avoid possible serious personal injury, do not cut more

than one loose piece of material at a time.

10 .110 in. .020 in. 1200-1550 Popular size for cutting hard and soft

woods 3/16 in. up to 2 in. Plastics, paper,

felt, bone, etc.

15 .110 in. .020 in. 600-1200 Wood, plastics, extremely thin cuts on

materials 3/32 in. to 1/2 in. thick.

18 .095 in. .010 in. 400-600 For tight radius work in thin materials

3/32 in. to 1/8 in. wood, veneer, bone,

fiber, ivory, plastic, etc.

WOOD

PIECES

TAPE

OPERATION