10

3. Place the Amp Probe around the starter cable.

4. Connect the external volts positive lead to the positive terminal

of the starter.

5. Connect the external volts negative lead to the starter ground.

6. Set the Volts Selector to External Volts ±199.9 volt range.

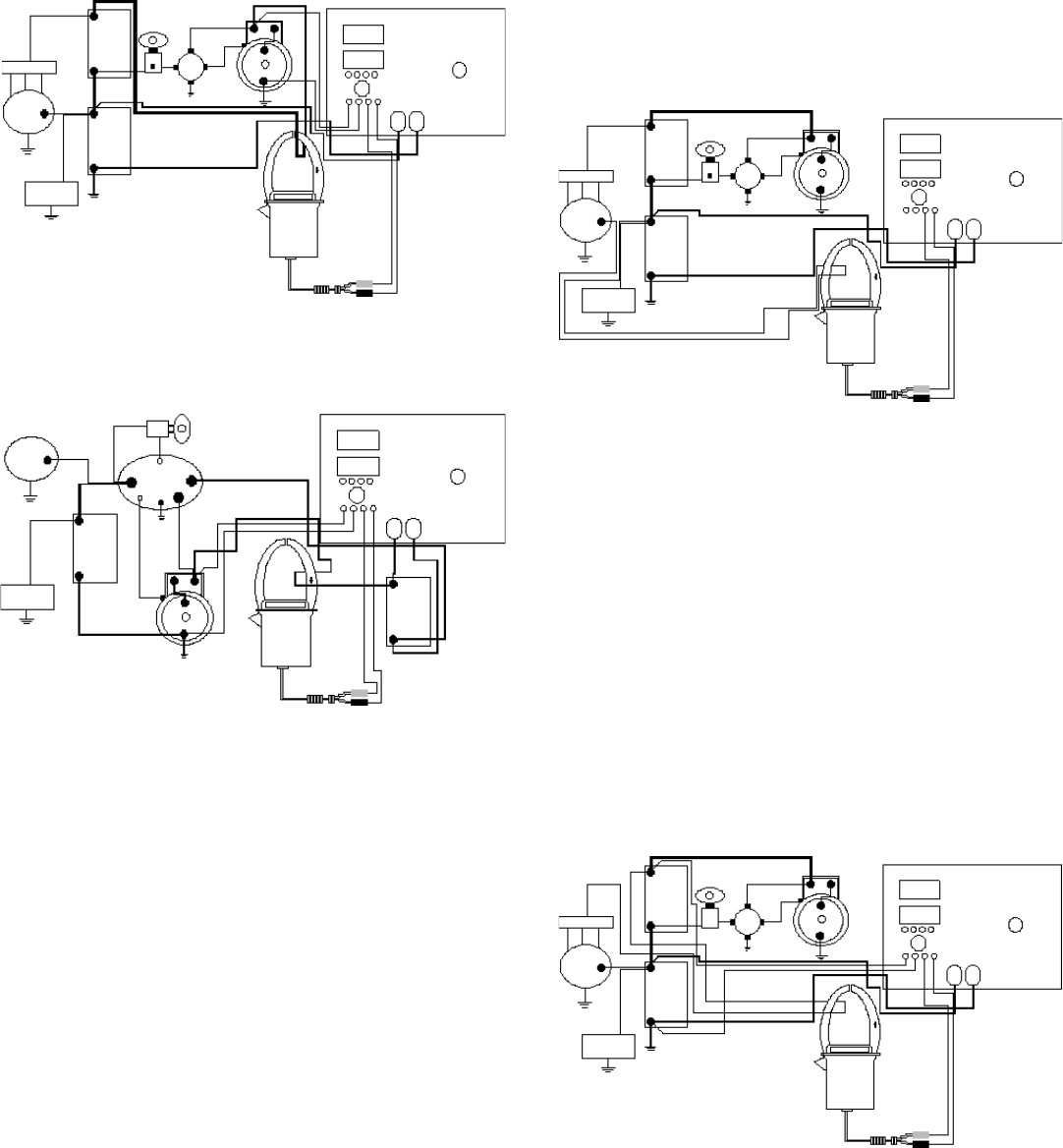

Figure 11

Transformer Rectifier Starter Draw Test

STARTER

CHASSIS

BATTERY

CRANKING

BATTERY

ALT

TR

+

+

-

+

-

12V LOADS

MAG

SW

S

+ 24V

+ 12V

Figure 12

Series-Parallel Switch Starter Draw Test

STARTER

CHASSIS

BATTERY

SWITCH

ALT

+

+

-

12V LOADS

CRANKING

BATTERY

+

-

SERIES

PARALLEL

SWITCH

Crank the engine for 15 seconds, and note the cranking amper-

age reading. Also, watch to see that the starter voltage stays

above 19.2 volts. Never crank the engine longer than 30 sec-

onds. Wait at least two minutes for the starter to cool, if the test

is to be repeated.

In some medium-duty applications, where there are two banks of

CRANKING batteries, it may be necessary to connect the Amp

Probe around both wires at once to read total current draw. If the

wires are too far apart for the Amp Probe, simply measure the

draw in each wire and add the results.

TEST CONCLUSIONS

The circuit is good if cranking speed was satisfactory and battery

voltage at the starter stayed above 19.2 volts. Slow cranking speed

is often caused by poor connections in the cranking circuit. Refer

to the PST-1000 manual for troubleshooting information. In a 24

volt circuit, acceptable voltage drops are twice those for 12 volt

circuits. If testing of the magnetic switch, solenoid, and other

components reveal no problems, the starter should be replaced.

ALTERNATOR OUTPUT CURRENT TEST

TRANSFORMER RECTIFIER

There are two separate output wires. A 12 volt, high current out-

put feeding the CHASSIS battery and a 24 volt, low current out-

put, feeding the CRANKING battery. (See diagram below).

TEST PROCEDURE

12 Volt Output

1. Connect the Analyzer’s load cables across the CHASSIS

battery.

2. Place the Amp Probe around the 12 volt output wire.

Figure 13

Transformer-Rectifier Alternator Output Test-12V

STARTER

CHASSIS

BATTERY

CRANKING

BATTERY

ALT

TR

+

+

-

+

-

12V LOADS

MAG

SW

S

+ 24V

+ 12V

3. Set the Volts Selector to Battery Volts.

4. Run the engine at about 2000 RPM.

5. Turn the Load ON and increase until the battery voltage is

between 12.5 and 13.5 volts while reading the output

amperage.

6. Turn the Load OFF and reduce RPM.

TEST CONCLUSIONS

1. If the Diode/Stator lamp stayed on during the output test,

replace the alternator.

2. If the amperage abruptly decreased during the test, check

for a loose belt.

3. If output was less than 90% of rating, see PST-1000 manual

for output resistance test procedures.

Figure 14

Transformer-Rectifier Alternator Output Test-24V

STARTER

CHASSIS

BATTERY

CRANKING

BATTERY

ALT

TR

+

+

-

+

-

12V LOADS

MAG

SW

S

+ 24V

+ 12V