9

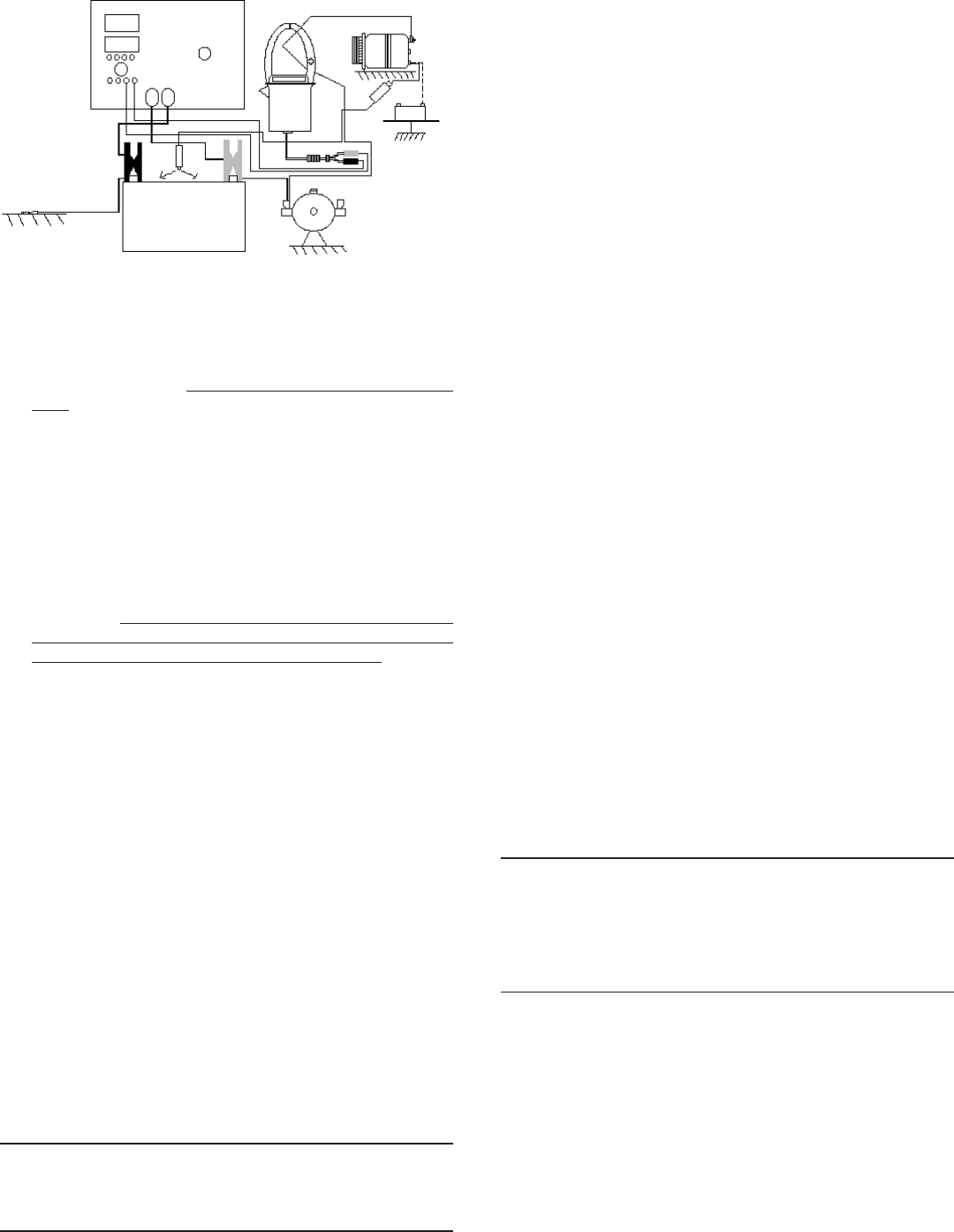

Figure 10

BLACK

SOLENOID

RELAY

BATTERY

CHASSIS

RED

+

+

-

A

B

DISCONNECT

REGULATOR

JUMPER

ALTERNATOR

OUT

FIELD

STEPS FOR EXTERNAL REGULATOR (TYPE) ALTERNA-

TOR

1. Make connections according to figure 10 above.

2. With ignition key OFF,

unplug regulator or disconnect field

wire.

3. Measure voltage at alternator field terminal. If at battery volts,

jumper the field terminal to the alternator case. If no volts,

jumper to the alternator output terminal. If there is no spark

when making this connection the field circuit is broken.

Continue to step 4.

STEPS FOR INTERNAL REGULATOR (TYPE) ALTERNATOR

1. Make connections according to figure 10 (above).

2. This test can only be done if the alternator has a terminal for

full fielding.

Be sure to have specific knowledge of the

alternator’s terminals. Grounding the wrong point can

damage some alternators or burn up jumpers. A 10 amp

(inline) fused jumper can help minimize accidental damage.

3. Apply, or prepare to apply the field excitation when the engine

is at idle. Get a helper if necessary.

Continued from step 3

4. Start the engine and slowly bring RPM to 2000. Keep battery

voltage between 12.5V and 13.5V by applying loading from

the analyzer.

Never let the voltage exceed 16 volts.

5. Remember the amps reading, and return to idle.

6. Shut off the engine, the battery load, and the alternator field.

7. Test Conclusion

a. If output was less than 90% of rating, go back to the

Output Resistance Test.

b. Otherwise if the output is okay, the problem must be in

the regulator or its wiring.

CAPABILITIES FOR 24V SYSTEM

The PST-1000 is capable of performing Battery Load tests, Starter

Draw tests, and Alternator Current Output tests on 24 volt electri-

cal circuit.

CAUTION

Working with batteries can be hazardous! Please read the

SAFETY PRECAUTIONS on the front page of the PST-1000

manual.

CIRCUIT ARRANGEMENTS

Most 24 volt circuits utilize combinations of 12 volts batteries to

provide 24 volts to the starter motor, controls and accessories. A

CHASSIS battery (or bank of batteries) is used for the engine’s

12 volt circuits, and a CRANKING battery (or bank of batteries)

is added to the circuit to provide 24 volts to the starter motor.

Occasionally you may encounter banks of six volt batteries, or

even a single 24 volt battery. Six volt batteries may be Load tested

individually or in pairs, if wired in series. NEVER attempt to Load

test a 24 volt battery with the PST-1000.

The two most common charging/starting arrangements are the

TRANSFORMER-RECTIFIER, used on most newer engines, and

the SERIES-PARALLEL switch.

Always refer to the engine manufacturer’s instructions prior to

conducting any tests, as some engines may have components

and circuit arrangements that are not included in these examples.

TRANSFORMER RECTIFIER

In a TRANSFORMER-RECTIFIER circuit, the CRANKING bat-

tery is always wired in series with the CHASSIS battery. The

TRANSFORMER-RECTIFIER alternator provides two separate

voltage outputs. A high current 12 volt output charges the CHAS-

SIS battery, and a low current 24 volt output charges the CRANK-

ING battery. The TRANSFORMER-RECTIFIER regulates the

charging voltage to both batteries automatically.

SERIES PARALLEL SWITCH

While charging, the CHASSIS battery and CRANKING battery

are switched in parallel. During cranking, the SERIES-PARAL-

LEL switch connects the CRANKING battery in series with the

CHASSIS battery, providing 24 volts to the starter motor.

The following procedures and diagrams apply to circuits with a

negative ground, a CHASSIS battery, a CRANKING battery, and

either a TRANSFORMER-RECTIFIER alternator or a SERIES-

PARALLEL switch.

BATTERY LOAD TEST

Batteries wired in series may be Load tested without disconnect-

ing cables. Those wired in parallel MUST be disconnected prior

to Load testing. Failure to do so will result in loading more than

one battery at a time and will yield inaccurate results. Perform

Load tests described earlier in the PST-1000 manual.

CAUTION

Always be sure that the Load is OFF before connecting the

analyzer’s Load cables to a battery.

To prevent damage to the SERIES-PARALLEL switch by high

current flow, batteries must be disconnected from the cir-

cuit prior to Load testing.

STARTER DRAW TEST

This test measures the amount of current drawn by the starter

motor during cranking. The procedures apply to both TRANS-

FORMER-RECTIFIER and SERIES-PARALLEL circuits. To pre-

vent the engine from starting, disable the ignition or fuel supply,

as recommended by the engine’s manufacturer.

TEST PROCEDURES

1. Connect the analyzer’s Load cables across any 12 volt

battery.

2. Make sure all lights and accessories are off and vehicle doors

are closed