STORAGE

Beforeyoustorethe air compressor,make sureyou do

the foflowlng:

1, Reviewthe'Maintsr_n_e" section onthe precaeding

pages and perform maintenan;e as necessary, Be

sure to drainw=terfromthe air la_k.

2. Protectthe etectficaJcord and air hosefromdamage

(such s8 _:>etOgsteppedon or _n over).Wind them

looselyamUr_l_the compressorhandle,

Store _heaircompressorin a cleanand dry IocaUon.

PR0.u .

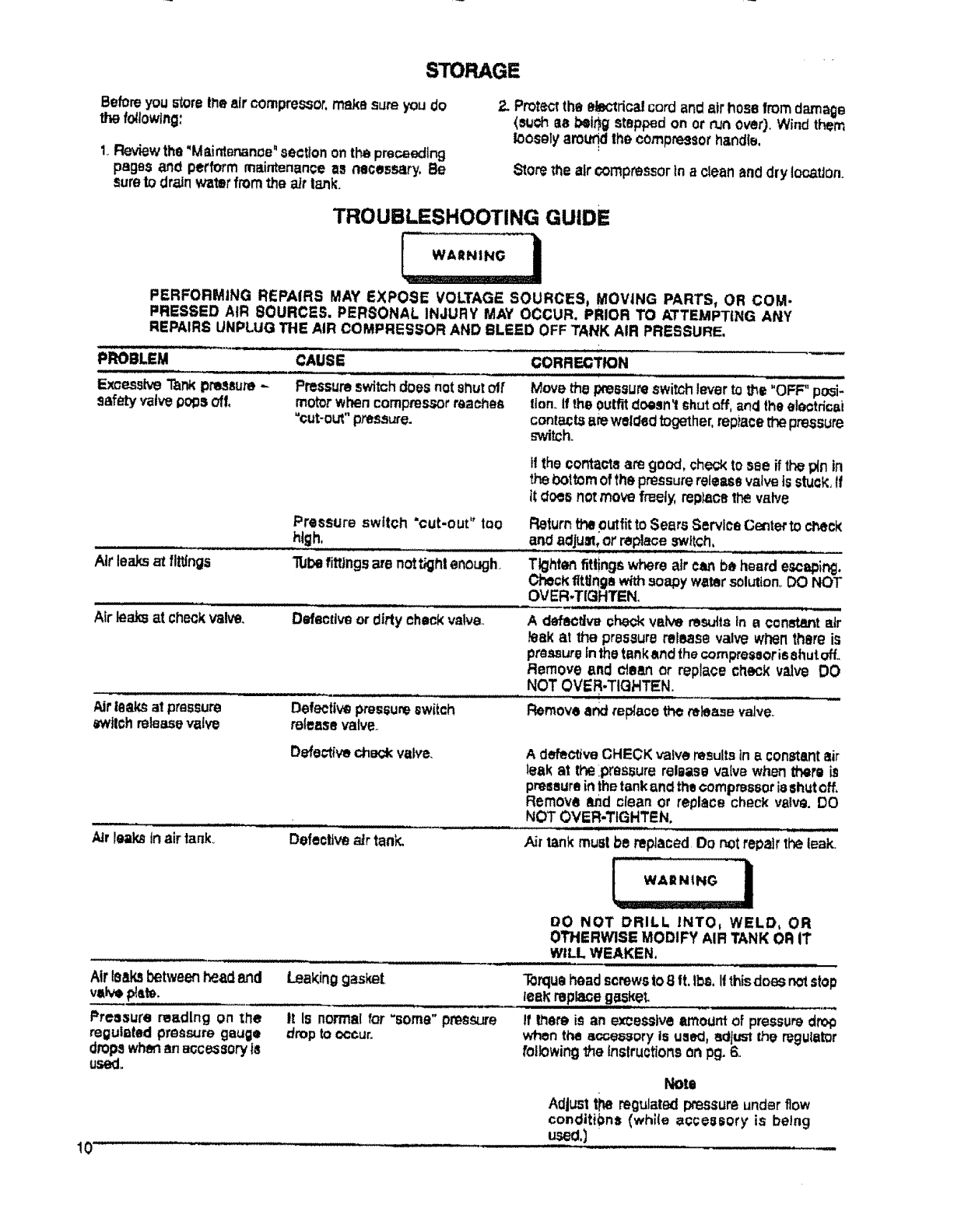

TROUBLESHOOTING GUIDE

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES_ MOVING PARTS, OR COM-

PRESSED AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY

REPAIRS UNPLUG THE AIR COMPRESSOR AND BLEED OFF TANK AIR PRESSURE.

...... cause............................CORR T .

Pressureswitchdoesnot shut olt" Move the pressureswitohleverto_e "OFF'I Po_i-

motor when compressorreaches lion. if the OUtfitdoesn1 shut off, an_lthe eleotricai

"cut-oUt"pressure, conlactsarewelc_edtogether,replacethepressure

switch.

Ex_essk,e _r_ pressure

safety valve Pol_soff,

Air leaks at fittings

Air leaks at checkvalve.

Airl@ak,_at pressure

_ltoh releasevalve

Defective pressure_witch

rolease valve.

II the contactsam good, checkto see if thepinin

thebottomofthe pressure relays valvetsstucK,if

it does not move freely,apace the vetve

Pressure switch "cut-out" tao Returnttleputfitto Sears ServleeCente_to check

high, anti aclju=,or replace switch,

ui, , .i. ,., , ...............................

Tubafiffingsare not_ht enough. Tightenfittingswl_re air can be he_a_esCaping_-_

Ohec!_fittings withsoapywater solution,,DO NOT

OVER-TIGHTEN,

Defectiveor dirty check valve. A defective check valve resultsIn a constant air

reel<at the pressure release valve when there is

pressureInthetankand the com_esaor isshutoff.

Remove and clean or replace check valve DO

NOT OVER-TIGHTEN.

Remove end replace the releasevalve..

Defectivech_;k v=lve,

Airleak_ inair tank_ Dofecttve air tank,

Air leaks betweenhead and

va_ #_te.

Pre=_ure reading on _he

regulated pressure gauge drop to occur°

dropswhen _n a_c_sory Is

used.

A defective CHECK valve resultsin e constant_ir

leak at t_ pressure relgase valve when there i_

pressurein thetank_nc_thecompressor isshut off.

Remove and clean or replace check valve. DO

NOT OVER-TiGHTEN,

AJrtank must be replaced Do notrepair tt_:leakl

i w.,.,.o....I

DO NOT DRILL INTO_ WELD, OR

OTHERWISE MODIFY AIR TANK OR tT

WILL WEAKEN,

Leakinggasket. Torquehead screwsto 8 It, Ibs, Itthisdoes notstop

leak replace gasket

m

It IS normal for "some" pressure If t_ere is an excessive amountof pressure drop

when the _essory is usecl,adjust _heregulator

following 1heinstructionson pg. 6.,

Note

Adjust tt_eregulated pressure under flow

conditibns (while a_cessory is being

use_,)

0 ..........