ASSEMBLY INSTRUCTIONS

Tools Needed for Assembly

* pipethreadsealant(not incJuded)

, an a,clJustable wrench for attaching the pressure

regulator

" a _t_0,socket or open end wrench for attaching the

wheelsand hose adaptan

" a 7/1_openand wrench for attaching the air pressure

gauges

, a _e °'he,v.Re'i"for Installing the pluginthe regulal_

, a %" open end wrenchto tightenhandlescrews

"s #2 philtipe screwdriver for attaching the control

cover

installing Wheels, Handle, Rubber Foot Strip

i WARNIN_ !

THE WHEELS AND HANDLE OO NOT PRO-

VIDE ADEQUATE CLEARANCE, $TABJLITY

OR SUPPORT FOR PULLING THE UNIT UP

AND DOWN STAIRS OR STEPS, THE UN[T

MUST I_ELtFT]_D, ORPUSHED UP A RAMP.

1. Dipthe handle grip Insoapywater and sttdeintoposi-

tionas shownon photoon page 6 orpage 12.

2, Attachthe handleto the insideofthecompressorsad-

diebyp_jshtngthe handleIn,unllitheslotinthehandle

engageswith the labs in the saddle,Pufithe handle

bsckar<l installthe two s<z_ws,one oneach sideof

the _e_ldte.Tightensecurely,

ittory be necemury to brace or support one

enU of the outfit when attaching the wheels

end the r_Jbber foot _trlp,because the air

compressor will have a tenden=y to tip.

3- Rsmove the protectivepaperstrip frOmth_ adhesive

backed rubber footstrip,Attachtherubberfootstrip to

the bottom of 1heairtitnkleg. Press firmlyinto place°

4. Attachone wheelto each sideof theair ¢omp_ssor.

Use one shoulder bott and one nut for each wheel,

Tighten securely.

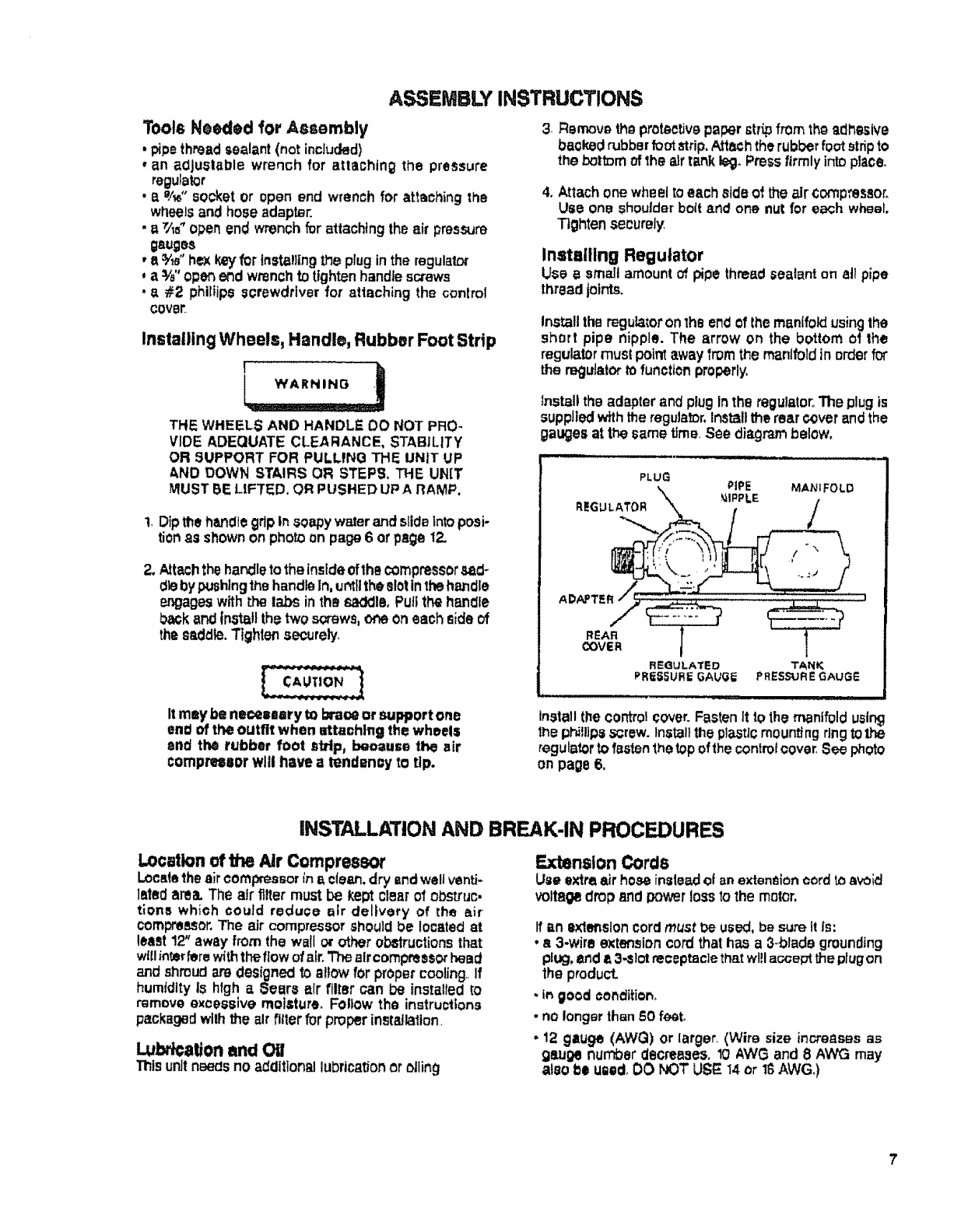

Installing Regulator

Use a small amountof,pipe thread sealant on aJipipe

thread joints.

Installthe regulatoron 1heendof lhe manifold using the

short pipe nipple. The arrow on the bottom ol the

regulatOrmust poi_ away from the manifold in order fo_

theregulatortofunctionproperly,

_nstalithe adapter and plugIn the regulator,,The plugis

supplied withthe regulator,Installthe rearcoverandthe

gauges at the same time,See diagrambelow,

R_ULATED

PRESSURE GAUG_

TANK

PRESSURE GAUGP-

tnstallthe control_over. FastenIt to the manifoldusing

the phillipsscrew.Installthe plasticmounting ringtothe

regulatortofastenthetopofthecontmtcover,See photo

on page 6.

INSTALLATION AND BREAK-IN PROCEDURES

Locationof the Air Compressor

Loca4ethe air compressorina ctean,dry endwelJventi-

lateclarea. The air filler must be kept clearo'l obstruc.

tlons which could reduce air delivery of the air

compressor.The air compressorshould be locatedat

least 12' away'fromthe wail or other obstructionsthat

wl!linterfere withtheftow of air. Theaircompressorhead

and shroudare designed to al!ow forpropercooling.,If

humidity Is high a _ears air filter can be installed iD

remove excessive moisture. Follow the instructions

packaged withthe air filter for proper installation,

LubricationandOil

Thtsunit n_eas no adcllttonal lubrication or otling

Extension Cords

Use extre,air hose insteaxJOf _nextensioncordto avoid

voltagedrop and power loss to the motor,

tf an axlet_slon cordmustt_ us'_, be sum it is:

. a 3-wire ext_._ion cord thath_ a _-,blade grounding

pll_, end !_3-_lotreceptacletigatwl!laccepttheplugon

the product,

. t_ good condition_

• no longerthan _50f_t.

.12 gtlUge (AWG) or larger. (Wire size increases as

gauge number _lecreaseso10 AWG and 8 AWG may

atso l_eused,OO NOT USt_t4 or 16AWG_)