2 - 7

(1) It is best to use only a small amount of adhesive on the tip of the ferrule. If

too much is used, sometimes it cannot be removed within the standard 30

seconds of hand polishing used to remove the adhesive.

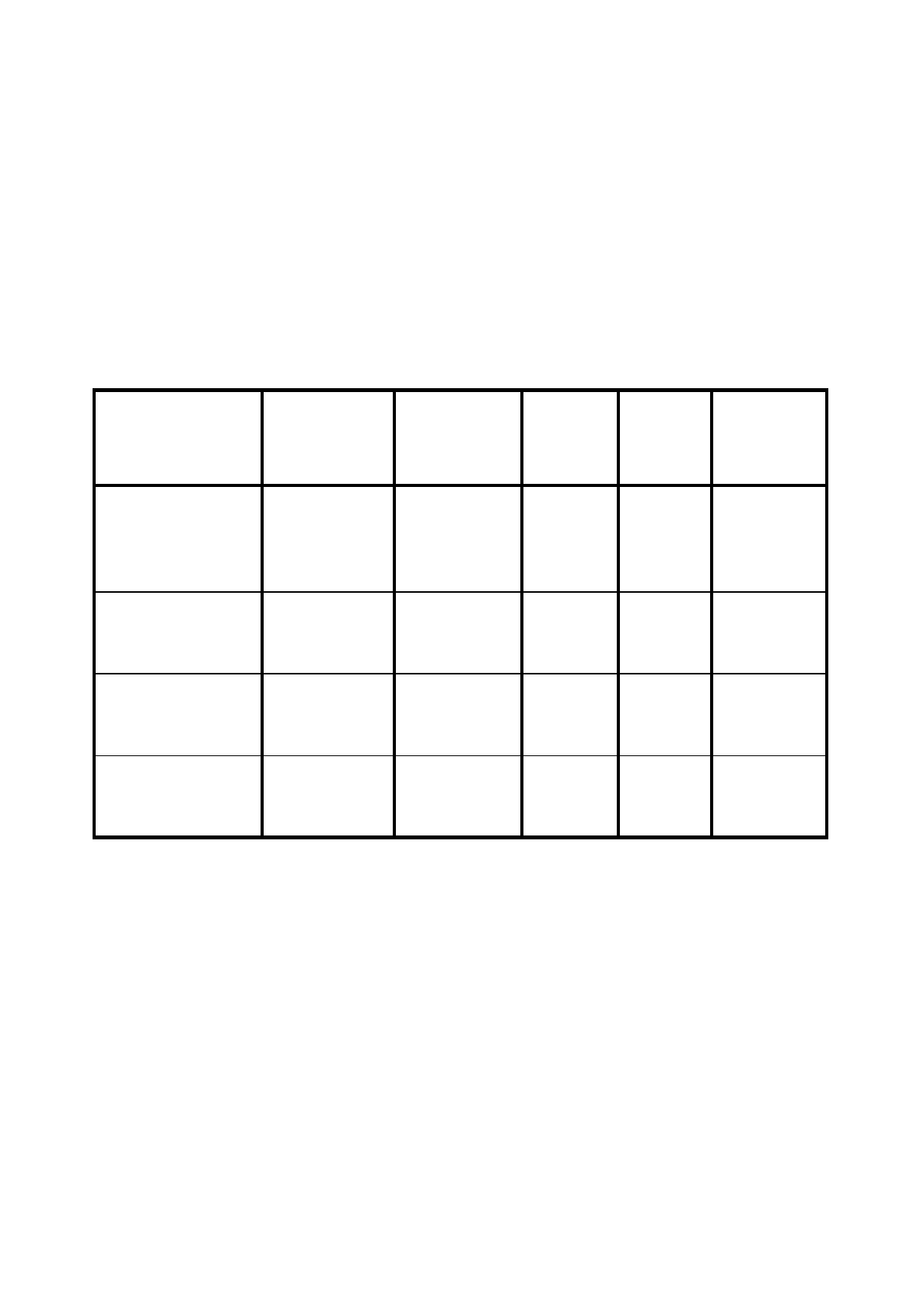

(2) The polishing film, polishing fluid, and polishing conditions used in each of

the polishing steps are listed in Table 2-1. Refer to the details for each of

the polishing steps in the corresponding sections.

Table 2-1 Polishing Media and Conditions

Polishing Step

Polishing

Film

Polishing

Fluid

Thrust

1

(Std.)

Polishin

g Time

(Std.)

Polishing

Film Life

Adhesive removal

(hand polishing)

abrasive

paper

(KJW100100)

none approx.

1 to 2 kg

(2.2 to

4.4 lbs)

30 sec. dispose of

every time

(max. 12

ferrules)

Grinding

(1st polishing)

green label

(KJW100200)

water Point 1 1 min.

30 sec.

10 times

(max. 120

ferrules)

Polishing

(2nd polishing)

yellow label

(KJW100300)

water Point 2 1 min.

30 sec.

10 times

(max. 120

ferrules)

Finishing

(3rd polishing)

white label

(KJW100400)

Polishing

fluid

(KJA100100)

Point 2 1 min. 10 times

(max. 120

ferrules)

1 The polishing thrust (pressure) varies according to the number of ferrules mounted in the holding

jig. Refer to section 3.3 for setting the thrust.

(3) Mount the ferrules in the holding jig evenly according to the explanation

given in section 4.1. When the ferrules are mounted incorrectly, the

ferrules can slip and the tips of the ferrules may not be polished correctly.

When mounting less than 12 ferrules in the holding jig, make sure they are

arranged in a balanced pattern, according to the explanation given in

section 4.1. An unbalanced arrangement of ferrules in the holding jig may

not be polished evenly.