3

3. Insert the gearbox into the coupling assembly.

4. Tip up the field and slide the gearbox/armature

assembly into location.

5. Reseat the field and make sure the armature spins

freely.

6. Remainder of assembly is the reverse of the removal

procedure above.

MOTOR COUPLING REMOVAL / INSTALLA-

TION

Removal

1. Remove the chuck as described above.

2. Remove the top housing half and gearbox as de-

scribed above.

3. Remove the armature from the tool as described

above.

4. The coupling is press fit onto the knurled end of the

motor shaft. Remove the coupling using an arbor

press or other suitable press. With the armature

pointed upward, the coupling should be held from the

bottom side and the armature pressed down.

Installation

1. Install a light film of moly based grease to the inside

of the coupling both in the large and small diameter

bores.

2. Remainder of the installation is the reverse of the

removal instruction above.

NOTE: It is very important that the coupling be lined up

properly during installation. Failure to install the

coupling straight will result in tool vibration.

MOTOR REMOVAL / INSTALLATION

Removal

1. Remove the chuck as described above.

2. Remove the top housing half and gearbox as de-

scribed above.

3. Remove the armature from the tool.

4. Disconnect the black and white lead wires from the

field and remove it. The thicker black jumper wire

should not be disconnected

NOTE: During disassembly, take note of wire routing so

the wires can be routed the same way upon reassembly.

Also take note of the way the two dowel pins on the fan

end of the field engage the lower housing.

Installation

1. Installation is the reverse of the removal instruction

above.

SWITCH REMOVAL / INSTALLATION

Removal

1. Remove the chuck as described above.

2. Remove the top housing half as described above.

3. Remove the reversing shuttle from the top of the

switch.

4. Disconnect the 4 leads from the reversing module

(top portion) of the switch. These should slide straight

up and disengage.

5. Loosen the two Phillips head machine screws on the

side of the switch and remove the power cord wires.

6. The red brush wire installed in the bottom of the

switch can be removed by pushing a small diameter

pin in the wire opening. This will open the wire trap

and the wire can be pulled out.

NOTE: Again, take note of the wire routing before disas-

sembly so they can be properly routed upon reassembly.

Installation

1. Installation is the reverse of the removal instruction

above.

CAUTION: It is extremely important that the wires that

terminate in the reversing module of the switch be properly

installed. When properly installed, the top of the terminals

will be about flush with the top of the switch. Proper

installation ensures adequate spacing between the switch

terminals, which are live, and the gearbox, which is metal

and has a conductive path to the chuck. Ensure that the

spacing between the switch terminals and gearbox is

adequate before reassembling the top housing half.

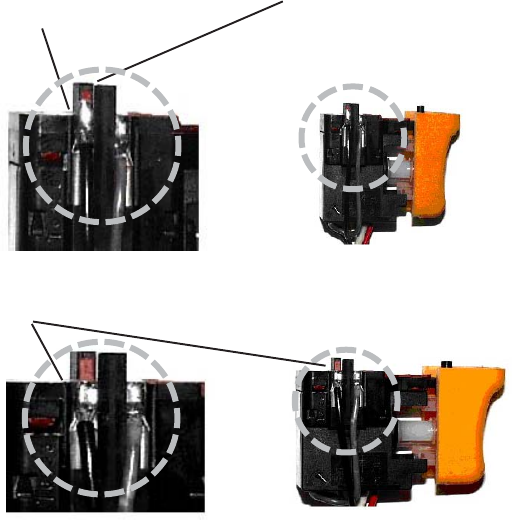

Improper Switch Wire Assembly

Terminals may not extend

beyond the top surface of

the switch.

100% inspect to see that the

terminal is pushed down all the

way and that there are no

excessive lumps of solder.

When properly installed, the terminals on the switch wires are

fllush with the top of the switch as shown in the pictures above.

Proper Switch Wire Assembly

100% inspect for proper connection.