-6-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

INTRODUCTION

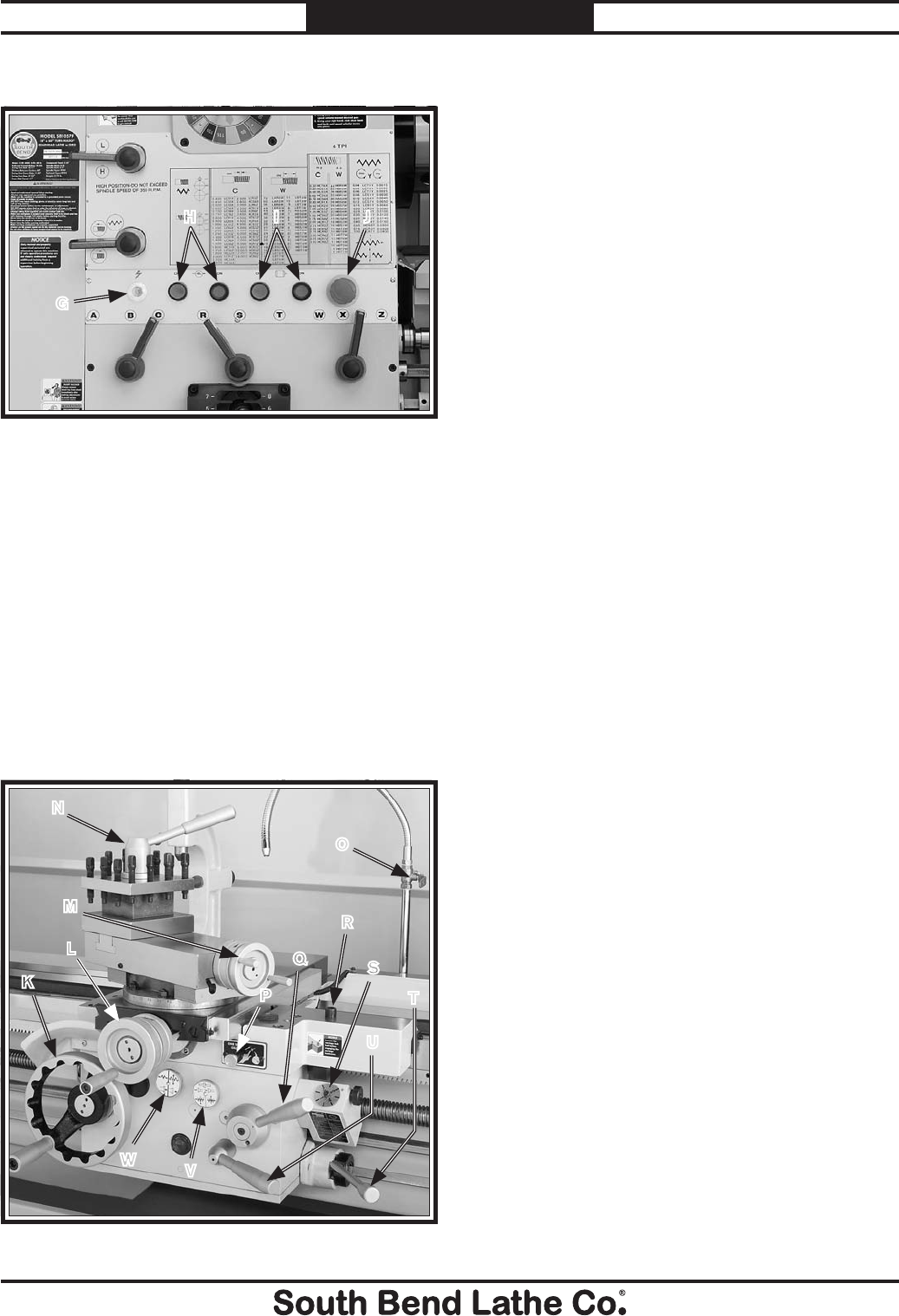

Control Panel

G. Power Light: Illuminates when lathe controls

are receiving power.

H. Coolant Pump OFF & ON Buttons: Control

the coolant pump motor.

I. Spindle Motor OFF & ON Buttons: Controls

the spindle motor.

J. STOP Button: Stops all machine functions.

Twist clockwise to reset.

Carriage

K. Carriage Handwheel: Moves the carriage

along the bed. Can be disengaged during

power feed operations to prevent an

entanglement hazard.

L. Cross Slide Handwheel: Moves the cross

slide toward and away from the workpiece.

M. Compound Rest Handwheel: Moves the tool

toward and away from the workpiece at the

preset angle of the compound rest.

N. 4-Way Tool Post: Mounts up to four cutting

tools at once that can be individually indexed

to the workpiece.

O. Coolant Flow Control Lever: Controls the

flow of coolant from the nozzle.

P. One-Shot Oiler: Draws oil from the apron

reservoir to lubricate the carriage ways

through various oil ports.

Q . Half Nut Lever: Engages/disengages the half

nut for threading operations.

R. Carriage Lock: Secures the carriage in place

when the carriage should not move.

S. Thread Dial and Chart: Dial indicates when

to engage the half nut during threading

operations. Chart indicates on which thread

dial reading to engage the half nut for

specific inch thread pitches.

T. Spindle Lever: Starts, stops and reverses

direction of spindle rotation.

U. Feed ON/OFF Lever: Engages/disengages

power feed.

V. Apron Feed Direction Knob: Changes

direction of carriage or the cross slide feed

without having to stop the lathe and move

the headstock feed direction lever.

W. Feed Selection Knob: Selects the carriage or

cross slide for power feed.

K

M

Figure 5. Carriage controls.

L

N

R

S

O

P

Q

U

V

W

T

Figure 4. Control panel.

G

H I J