-90-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

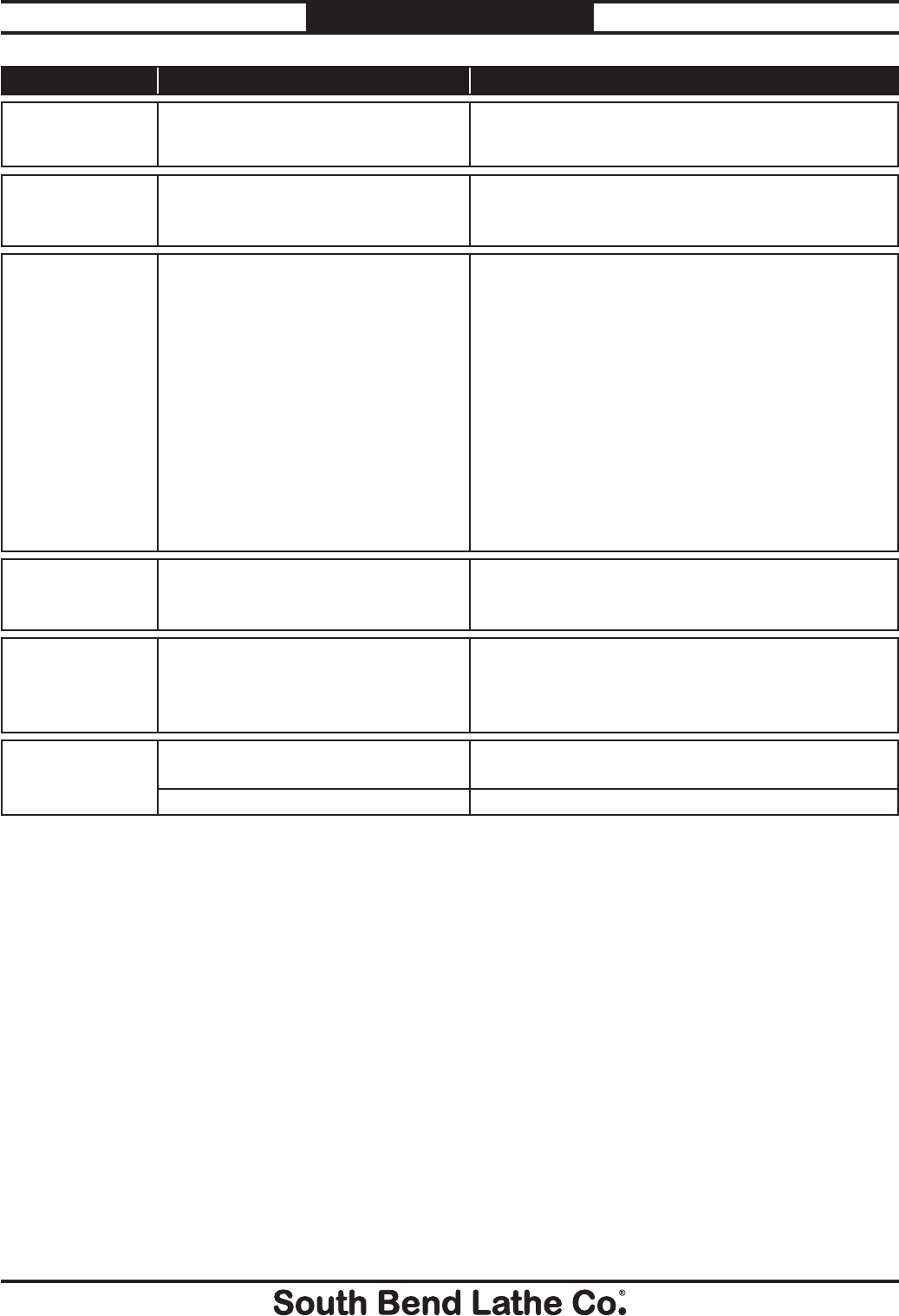

TROUBLESHOOTING

Gear change levers

will not shift into

position.

1.

Gears not aligned inside headstock.

1.

Rotate spindle by hand with light pressure on the

lever until gear falls into place.

Spindle clutch

takes more than

3–4 seconds to

engage.

1.

Spindle clutch mechanism is too

loose.

1.

Adjust spindle clutch (see Page 81).

Difficulty engaging

spindle lever.

1.

(When new) Spindle clutch needs

break-in time.

1.

Use moderate pressure to engage spindle lever until

it is broken-in.

2.

Spindle clutch is too tight.

2.

Adjust spindle clutch (see Page 81).

Carriage will not

feed or is hard to

move.

1.

Gears are not all engaged.

1.

Adjust gear levers.

2.

Carriage lock is tightened down.

2.

Check to make sure the carriage lock bolt is fully

released.

3.

Loose screw on the feed handle.

3.

Tighten.

4.

Chips have loaded up on bedways.

4.

Frequently clean away chips that load up during

turning operations.

5.

Bedways are dry and in need of

lubrication.

5.

Lubricate bedways and handles.

6.

Micrometer stop is interfering.

6.

Check micrometer stop position and adjust it as

necessary (see Page 52).

7.

Gibs are too tight.

7.

Loosen gib screw(s) slightly (see Page 78).

8.

Gears or shear pin broken.

8.

Replace gears or shear pin (see Page 84).

Symptom Possible Cause Possible Solution

Workpiece is

tapered.

1.

Spindle and tailstock centerlines

are not properly aligned with each

other.

1.

Realign the tailstock to the headstock spindle bore

centerline (see Page 45).

Chuck jaws will

not move or do not

move easily.

1.

Chips lodged in the jaws or scroll

plate.

1.

Remove jaws, clean and lubricate scroll plate, then

replace jaws.