For Machines Mfg. Since 3/11 Turn-Nado

®

Gearhead Lathes

-83-

SERVICE

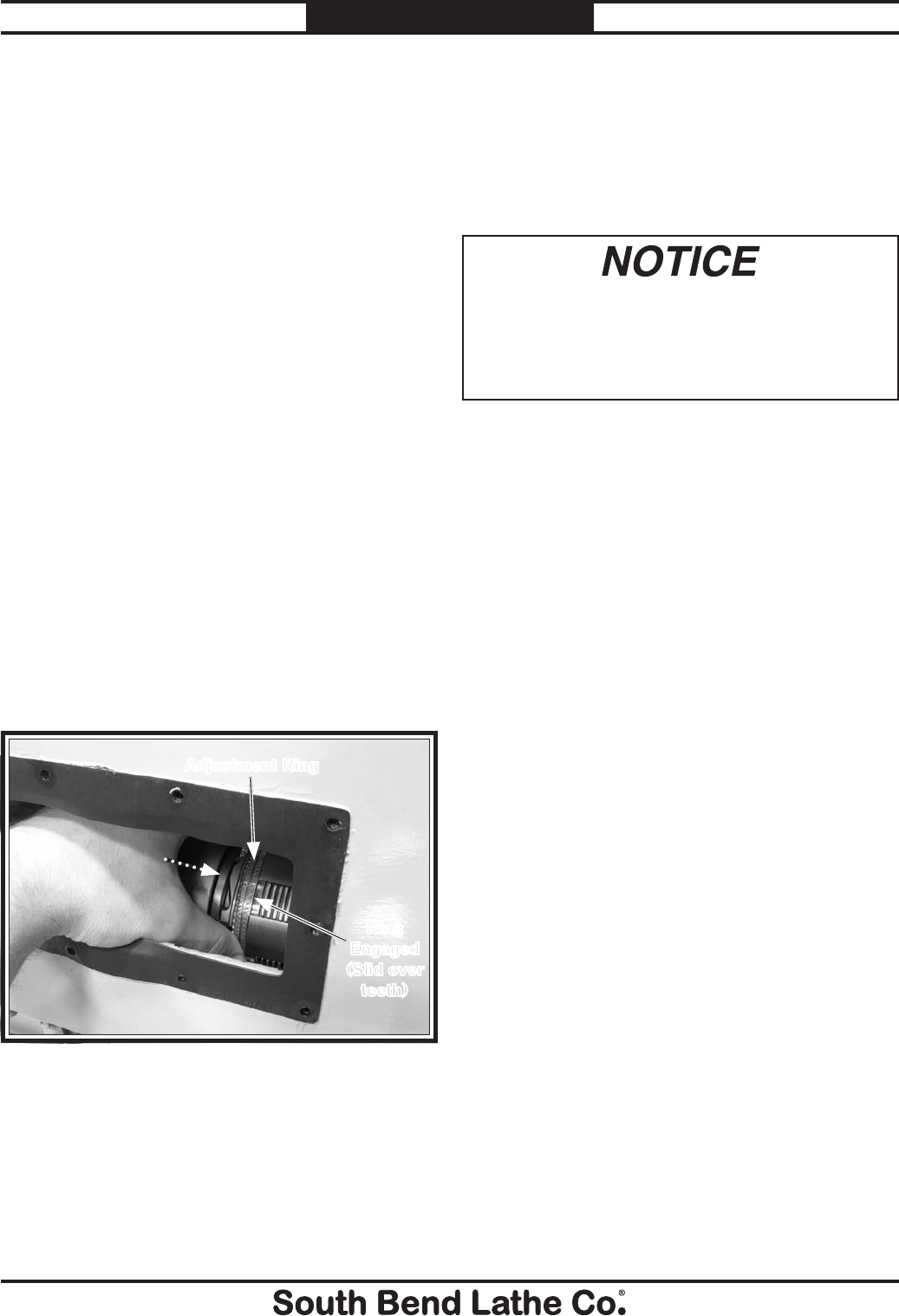

8. Loosen the appropriate adjustment ring one

notch, then remove your hand from inside

the headstock. Have an assistant try to

engage the troublesome lever position while

you manually rotate the input pulley on the

headstock. DO NOT rotate the pulley while

your hands are inside the headstock.

Tip: When rotating the adjustment ring, hold

the adjustment ring stationary and rotate the

input pulley to make the adjustment.

Continue loosening and testing until the

lever engages the troublesome position.

When you are satisfied with the loosened

setting, slide the adjustment ring towards

its clutch assembly to lock it in position (see

Figure 126). Skip to Step 10.

Figure 126. Engaging adjustment ring (reverse side

shown).

Adjustment Ring

Ring

Engaged

(Slid over

teeth)

10. Replace the clutch access cover, pivot the

electrical cabinet back into position and

secure it with the fasteners removed in Step

3. If you removed the chuck guard safety

switch or work lamp, replace them.

11. Re-connect the lathe to power, then check

the function of the lathe. Test on the highest

speed setting allowed for the chuck being

used. Use a 3-jaw chuck with no workpiece

mounted. The spindle should take no more

than 3–4 seconds to reach full speed. Repeat

the clutch adjustment procedure as needed.

9. Tighten the adjustment ring one notch, then

slide the adjustment ring towards its clutch

assembly to lock it in position.

Tip: When rotating the adjustment ring, hold

the adjustment ring stationary and rotate the

input pulley to make the adjustment.

Do not attempt to over-tighten the clutch

to reduce spin-up time. 3-4 seconds is the

normal time required for the spindle to reach

full speed. Overtightening the clutch may

result in damage and improper lathe function.