-60-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

OPERATION

Note: In the next step, use the chuck key to rock

the spindle back and forth to help mesh the

gears as you make adjustments.

3. For a metric thread pitch of 2.5mm, use the

configuration string of characters to the

right of the selected thread pitch (LCR3Z) to

position the threading controls as follows:

L Move the gearbox range lever to the low

position.

C Point the left gearbox lever to the C.

R Point the middle gearbox lever to the R.

3 Position the bottom gearbox lever in the

3 slot.

Z Point the right gearbox lever to Z.

The lathe is now setup to cut a 2.5mm thread

pitch.

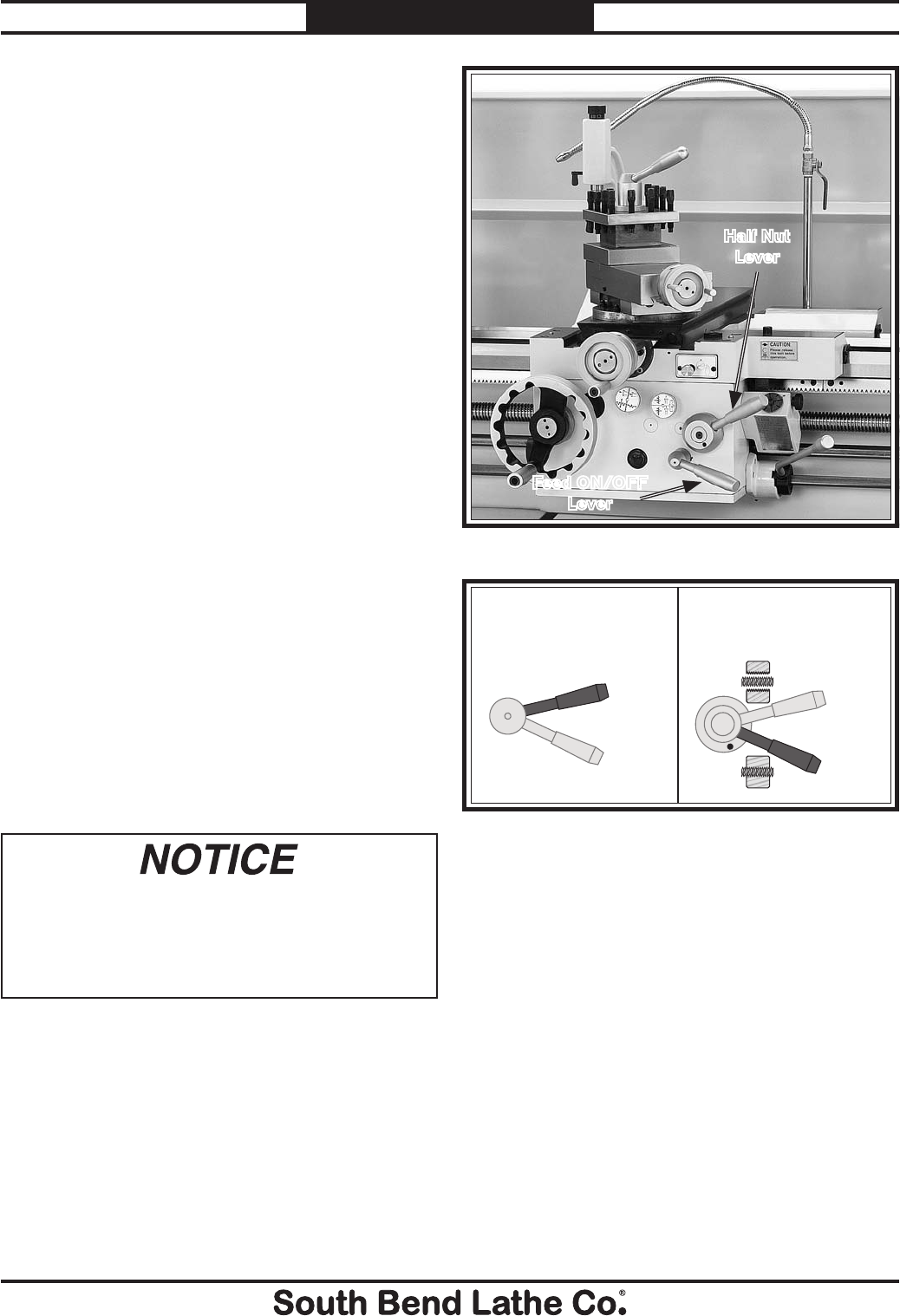

Apron Controls

The half nut lever engages the apron with

the leadscrew which moves the carriage and

cutting tool along the length of the workpiece for

threading operations (see Figures 78–79).

Important: Make sure the feed control lever

is in the disengaged (middle) position before

attempting to engage the half nut.

Engaged

Disengaged

Engaged

Disengaged

Half Nut Lever

and Half Nut

Feed ON/OFF

Lever

Figure 79. Feed ON/OFF lever and half nut positions

for threading.

Attempting to engage the half nut while the

cross slide or carriage is engaged with the

feed rod could cause severe damage to the

lathe. Never attempt to engage the half nut

while the feed control lever is engaged.

Figure 78. Carriage controls.

Feed ON/OFF

Lever

Half Nut

Lever