For Machines Mfg. Since 3/11 Turn-Nado

®

Gearhead Lathes

-69-

MAINTENANCE

4. Staying well away from the V-belts, re-

connect the lathe to power and press the

spindle motor ON button—DO NOT start

spindle rotation!

This will pump oil from the tank into the

bucket.

5. When oil stops flowing out of the supply

hose, immediately press the spindle motor

OFF button and disconnect the lathe from

power.

6. Place the low-profile catch pan under the

drain plug shown in Figure 98, then remove

the drain plug and let the remaining oil flow

from the tank.

Figure 98. Headstock oil drain plug.

Drain

Plug

7. Re-install the drain plug and re-connect the

oil supply hose to the headstock connection.

Note: Use pipe tape or sealant to ensure the

connections do not leak.

8. Clean away any spilled oil with shop rags

and mineral spirits.

9. Dispose or recycle the old oil according to

federal, state, and local requirements.

10. Add oil as previously instructed, then re-

install the end gear cover and side access

panel before re-connecting the lathe to

power.

Quick-Change Gearbox

Oil Type ......Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount ............................................ 3.2 Quarts

Check/Add Frequency ....................................Daily

Change Frequency ...................................Annually

Checking Oil Level

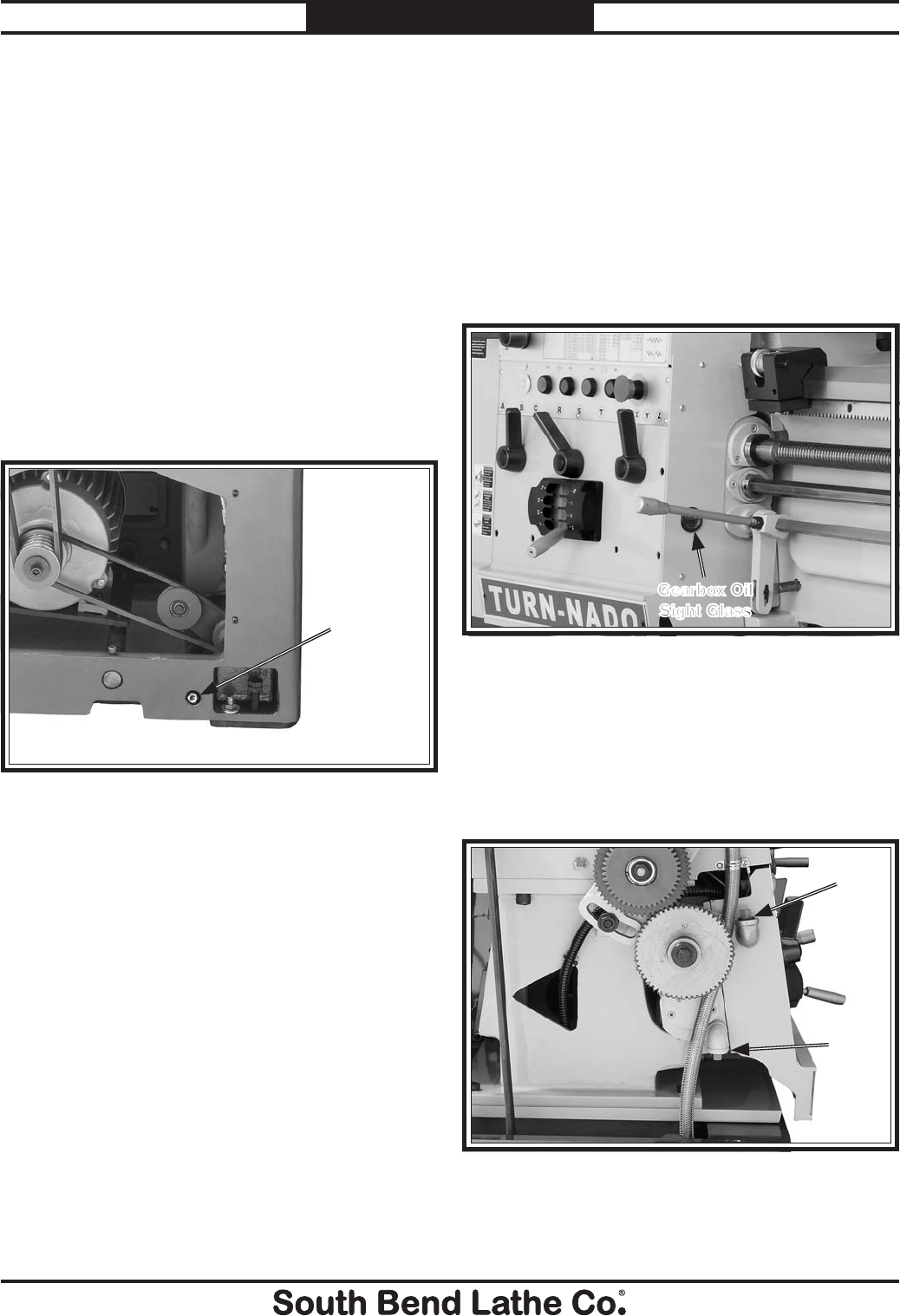

The quick-change gearbox has the proper amount

of oil when the sight glass shown in Figure 99 is

halfway full.

Adding Oil

Remove the quick-change gearbox fill plug (see

Figure 100), then add oil until the level is

approximately halfway in the gearbox oil sight

glass.

Figure 99. Location of quick-change gearbox oil sight

glass.

Gearbox Oil

Sight Glass

Figure 100. Locations of the quick-change gearbox fill

and drain plugs.

Fill

Plug

Drain

Plug