HG60 User Manual ◄ 13

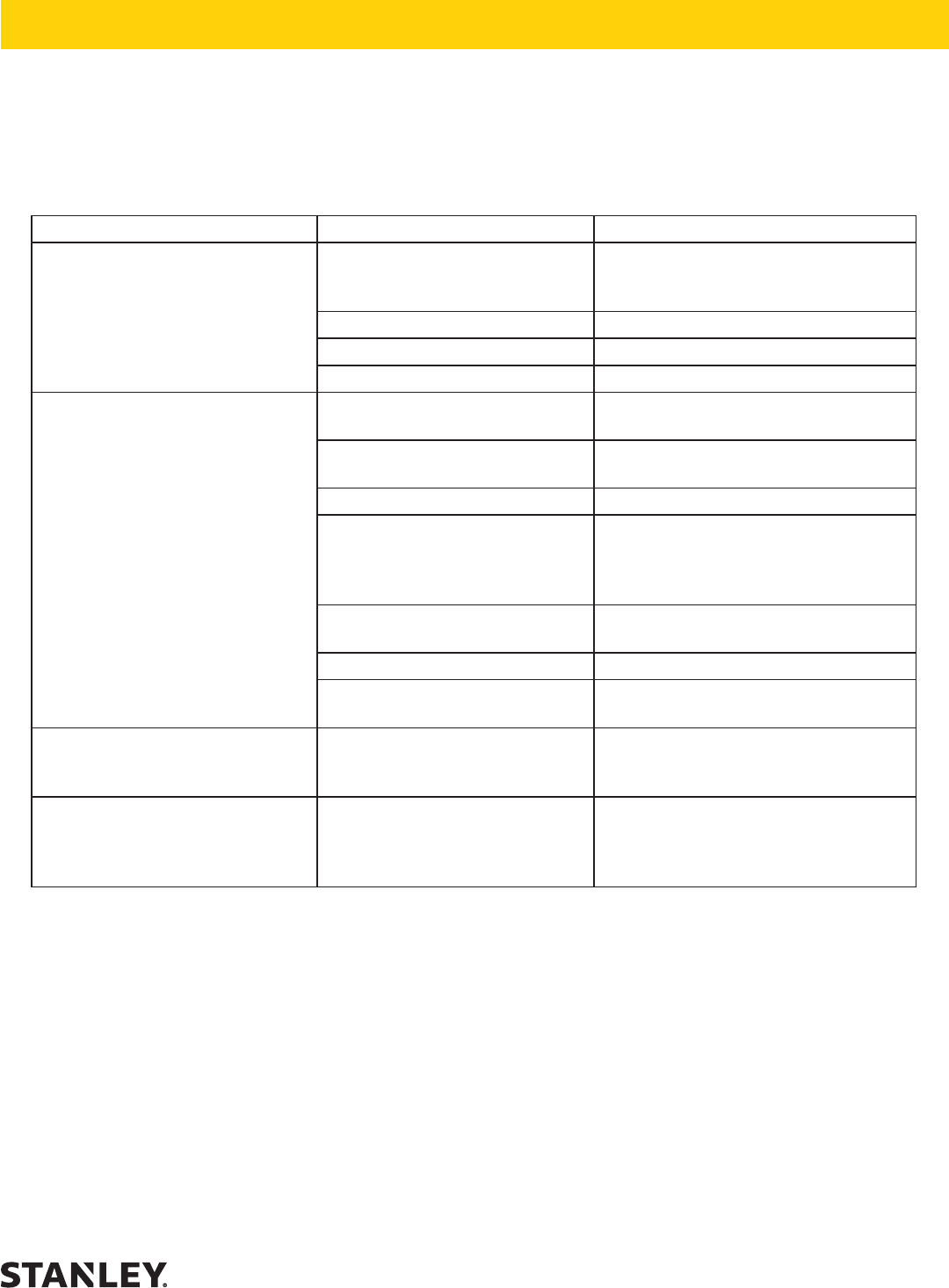

Problem Cause Solution

Grinder does not run. Hydraulic power source not

functioning.

Check power source for proper ow

and pressure (7–10 gpm/26–38 lpm @

1500–2000 psi/105–140 bar.

Couplers or hoses blocked. Locate and remove restriction.

Hydraulic motor failure. Inspect and repair.

Hydraulic lines not connected. Connect lines.

Grinder operates too slow. Hydraulic motor speed to slow. Check power unit for proper ow (7–10

gpm/26–38 lpm).

High back-pressure. Check hydraulic system for excessive

back-pressure (over 250 psi/17 bar).

Couplers or hoses blocked. Locate and remove restriction.

Oil too hot (above 140 °F/60 °C)

or too cold (below 60 °F/16 °C).

Check hydraulic power source for

proper oil temperature. Bypass

cooler to warm oil or provide cooler to

maintain proper temperature.

Relief valve set too low. Adjust relief valve to 2200–2300

psi/152–159 bar.

Hydraulic motor worn. Inspect, repair or replace.

Flow control malfunctioning. Have ow control serviced at an

authorized Stanley service center.

Grinder operates too fast. Flow control malfunctioning. Have ow control and valve body

serviced at an authorized Stanley

service center.

Spindle rotates in the wrong

direction.

Hydraulic ow is in the wrong

direction.

Connect the pressure line to the

grinder port marked IN. Connect the

return line to the grinder port marked

OUT.

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the grinder, always check that the hydraulic power source is supplying the

correct hydraulic ow and pressure to the grinder as listed in the table. Use a owmeter known to be accurate.

Check the ow with the hydraulic oil temperature at least 80 °F/27 °C.

TROUBLESHOOTING