12 ► PG10 User Manual

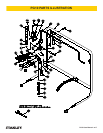

1. The gears and bearings in the ram, spindle, and

housing assemblies should be regreased every 6

months or 500 hours. This procedure must be ac-

complished by a trained technician.

2. After each servicing, measure the spindle speed

(rpm – revolutions per minute) at 12 gpm/45 lpm in-

put. The nominal speed is 4000, not to exceed 6000

rpm. This procedure must be accomplished by a

trained technician.

3. Inspect the spindle and drive ange for signs of

wear or damage. Run out should not exceed .004

in./.1 mm TIR on threads or .002 in./.05 mm TIR on

arbor diameters and faces.

4. Check hoses and ttings weekly for any evidence of

leakage, cover wear, cracking or cuts. If any of these

defects are found, discontinue use of the tool imme-

diately and have the defects repaired or replaced by

a trained technician.

PREVENTATIVE MAINTENANCE