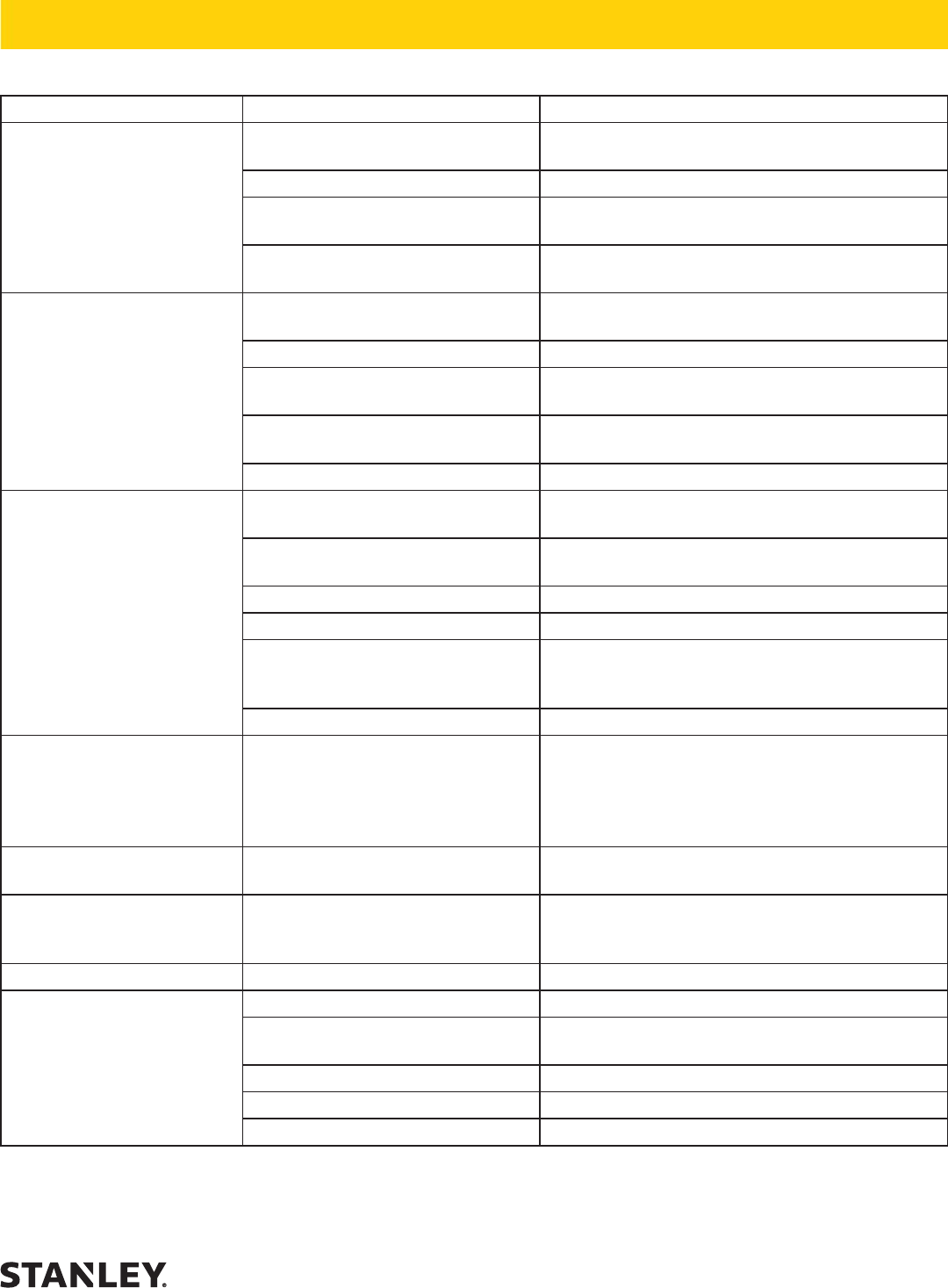

SK58 User Manual ◄ 13

PROBLEM CAUSE REMEDY

Tool does not run. Power unit not functioning. Check power unit for proper ow and pressure

(7–9 gpm/26–34 lpm, 1500–2000 psi/105–140 bar.

Couplers or hoses blocked. Remove restriction.

Pressure and return line hoses

reversed at ports.

Be sure hoses are connected to their proper ports.

Mechanical failure of piston or

automatic valve.

Disassemble breaker and inspect for damaged

parts.

Tool does not drill effectively. Power unit not functioning. Check power unit for proper ow and pressure

(7-9 gpm/26-34 lpm, 1500-2000 psi/105-140 bar.

Couplers or hoses blocked. Remove restriction.

Low accumulator charge (pressure

hose will pulse more than normal).

Recharge accumulator. Replace diaphragm if

charge loss continues.

Fluid too hot (above 140.°F/60.°C). Provide cooler to maintain proper uid

temperature (130 °F/55 °C).

Insufcient air or water. 20 cfm minimum.

Tool operates slow. Low gpm supply from power unit. Check power unit for proper ow (7–9 gpm/26–34

lpm).

High back-pressure. Check hydraulic system for excessive back-

pressure (over 250 psi/17 bar).

Couplers or hoses blocked. Remove restriction.

Orice plug blocked. Remove restriction.

Fluid too hot (above 140 °F/60 °C)

or too cold (below 60 °F/16 °C).

Check power unit for proper uid temperature.

Bypass cooler to warm the uid or provide cooler

to maintain proper temperature.

Relief valve set too low. Adjust relief valve to 2100–2250 psi/145–155 bar.

Tool gets hot. Hot uid going through tool. Check power unit. Be sure ow rate is not too

high causing part of the uid to go through the

relief valve. Provide cooler to maintain proper uid

temperature (140 °F/60 °C max).

Check the relief valve setting.

Fluid leakage on drill steel. Lower piston or drive hex seal

failure.

Replace seals.

Fluid leakage through charge

valve cap.

Upper piston seal failure or

accumulator O-ring failure or

accumulator charge loss or failure.

Replace seals, recharge or replace accumulator

diaphragm.

Fluid leakage around trigger. Valve spool seal failure. Replace seals.

Low rotation torque. Motor not completely broken in. Continue operation to break in motor.

Excessive oil temperature causes

operating pressure loss.

Provide cooler to maintain oil temperature (under

140 °F).

Damage to motor clearances. Repair as required.

Insufcient air or water. 20 cfm minimum.

Mechanical binding during drilling. Take care to guide drill straight.

TROUBLESHOOTING