-6-

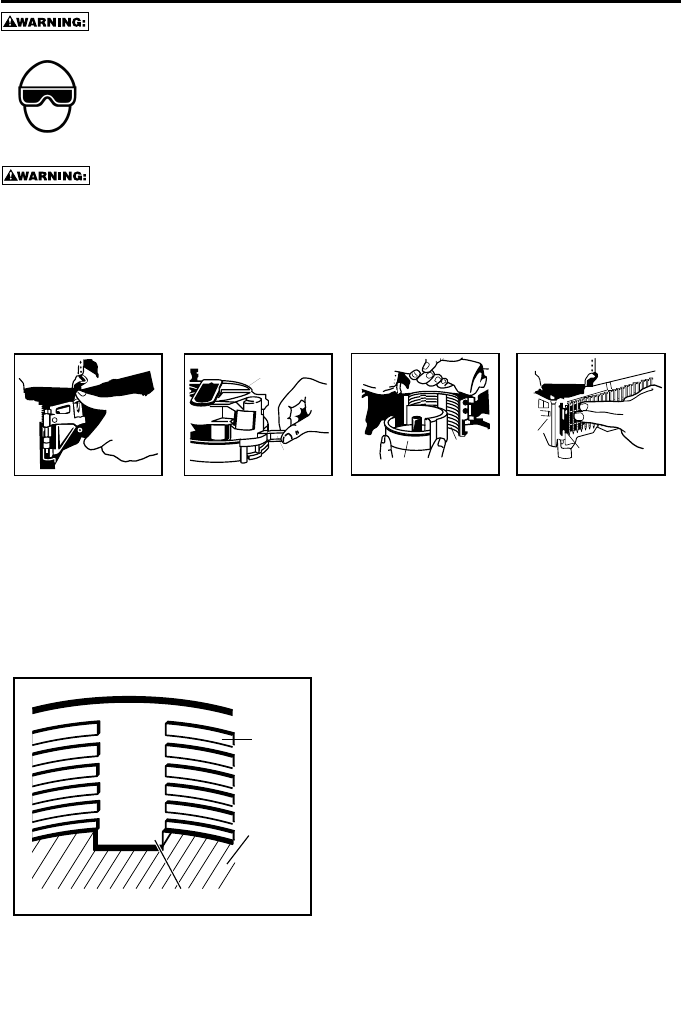

1. Open the magazine: pull down down latch and swing door open. Swing magazine cover open.

2. Check adjustment: the nailer must be set for the length of nail to be used. Nails will not feed

smoothly if the magazine is not correctly adjusted.

The N80CB accepts from 1-1/2” to 3-1/4” nails.

To change setting:

a) Release the canister latch on the rear of the canister.

b) Pull out canister bottom by swinging right to left until tabs disengage.

c) Inside the canister bracket are settings in inches and millimeters. The canister is adjusted correctly

when the length of the nail being used is shown in the window of the canister bottom.

C

anister

bracket

Canister

bottom

C

anister

c

over

C

anister

latch

Feed pawl

Door

C

anister

bracket

Canister

bottom

C

anister

c

over

C

anister

latch

Feed pawl

Door

Canister

bracket

C

anister

bottom

C

anister

cover

C

anister

latch

Feed pawl

D

oor

Canister

bracket

C

anister

bottom

C

anister

cover

C

anister

latch

Feed pawl

D

oor

3. Load the coil of nails:

Place a coil of nails over the post in the canister.

Uncoil enough nails to reach the feed pawl, and

place the second nail between the teeth on the

feed pawl. The nail heads fit in slot on nose.

4. Swing cover closed.

5. Close the door.

Check that latch engages. (If it does not engage,

check that the nail heads are in the slot on the

nose).

Note: The canister is adjusted correctly for 1-1/2”

and 1-3/4” nails when “1-3/4 (45)” appears in the

window of the canister bottom.

NOTE: Use only nails recommended by Bostitch for use in Bostitch N80CB Series nailers or

nails which meet Bostitch specifications.

Canister

bracket

Window

Canister

bottom

IN.

1 3/4

2

2 1/4

2 1/2

2 3/4

3

3 1/4

MM

(45)

(50)

(57)

(65)

(70)

(75)

(83)

LOADING THE N80CB SERIES COIL NAILER

E

YE PROTECTION which conforms to ANSI specifications and provides protection against

f

lying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

o

thers in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

s

pectacles and face shields alone do not provide adequate protection.

T

O PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in nail discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed at the work.

• Always handle the tool with care.

• Do not pull the trigger or depress the trip mechanism while loading the tool.