23

MAINTENANCE

4. Thoroughly clean the valve assembly with solvent

and brush.

5. A properly seated valve filled with water and held

vertically will not drip out the bottom of the valve. If

you have properly cleaned the valve and water drips

out the bottom, the valve is worn and needs to be

replaced.

6. Install cleaned or new valve in the pump block and

then fill the valve with light oil or solvent.

7. If none of the above steps work, see Troubleshoot-

ing.

NOTE: The inlet valve must be oiled after every job.

This will reduce or eliminate priming problems the next

time the sprayer is used. See Figure 43.

Cleaning and Servicing Outlet Valve

It may be occasionally necessary to remove and clean the

outlet valve or replace normal wear parts inside the valve.

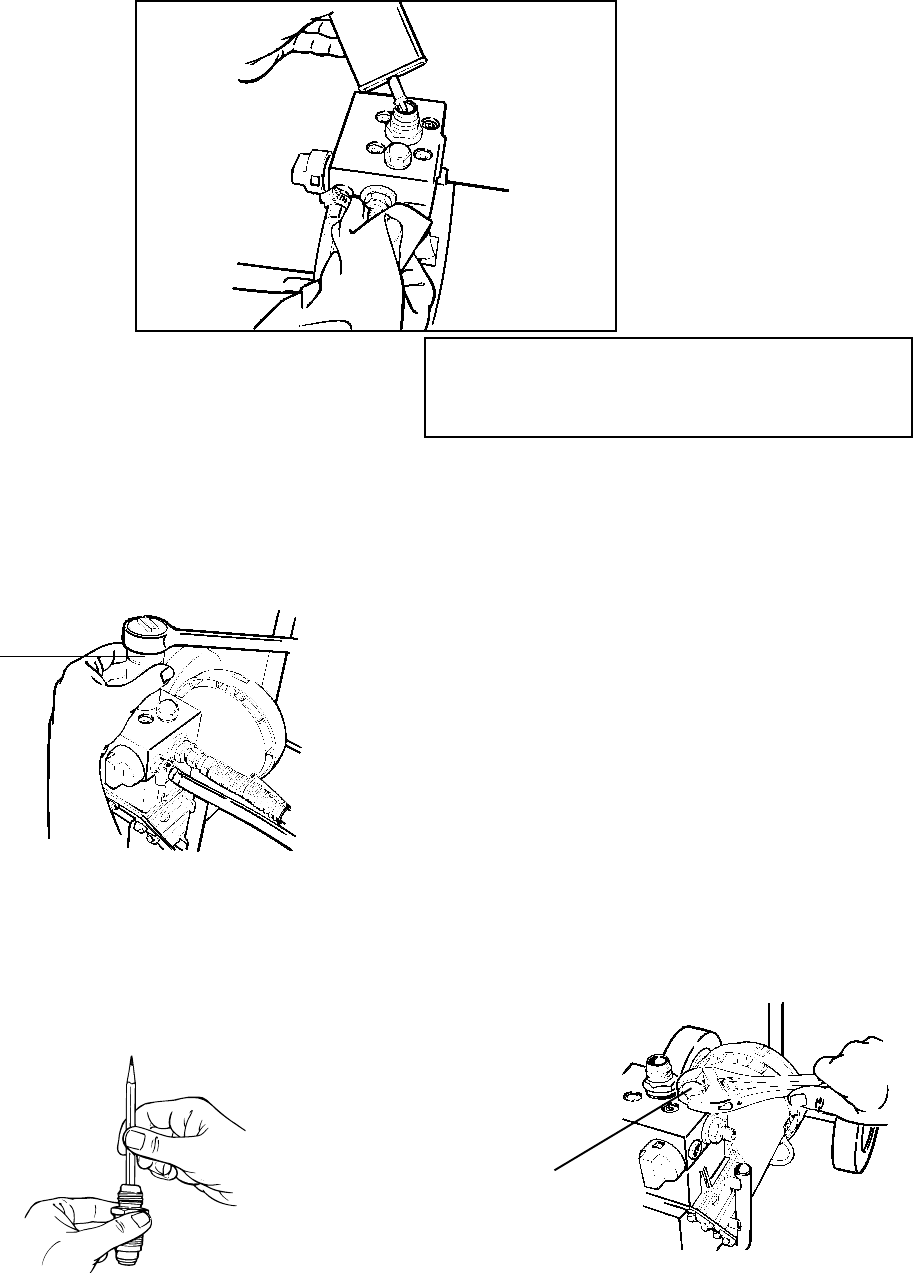

See Figures 47 and Figure 48.

1. Remove outlet cap with adjustable wrench.

Figure 47 - Removing Outlet Valve

CLEANING VALVES

Outlet Valve

Figure 46 - Test Movement of Valve

3. Test movement of the valve by pushing on it from the

open end of the valve housing with the eraser end of

a pencil or a screwdriver. It should move about 1/16

inch. If it doesn't move, it is probably full of dry paint

or other debris and should be cleaned or replaced.

Remove

Inlet Valve

Figure 45- Removing Inlet Valve

Removing and Cleaning Inlet Valve

1. Be sure sprayer is off.

2. Using a 27 millimeter socket or box end wrench,

remove the inlet valve assembly.

Follow these procedures when encounter-

ing problems indicated in the trouble shoot-

ing section.