25

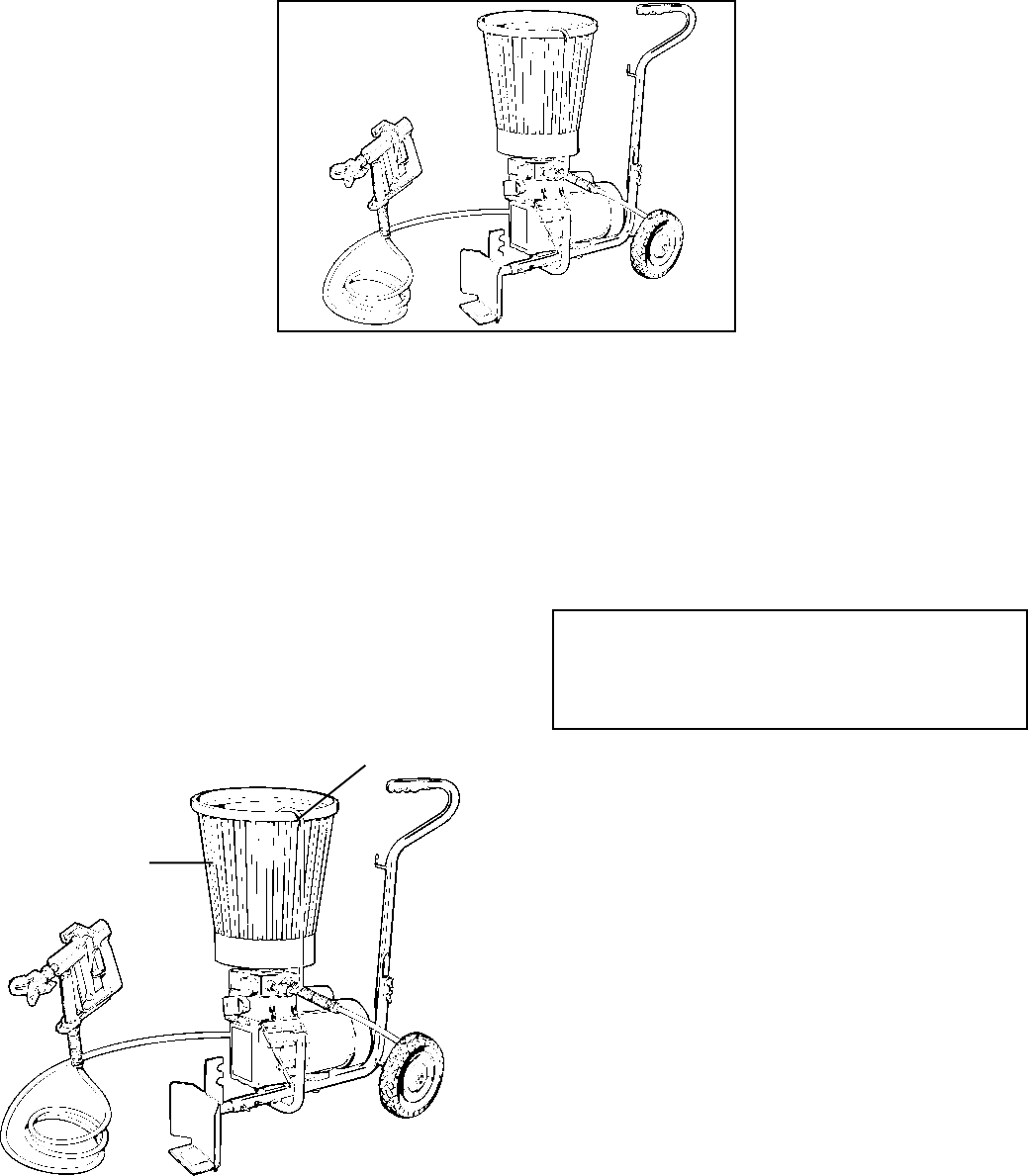

OPTIONAL HOPPER ASSEMBLY

CONVERTING SPRAYER FOR HOPPER OPERATION

Hopper Return Tube

Hopper

Figure 49 - Optional Hopper

4. Screw in the plastic return tube fitting into the paint

pump port that the brass fitting was removed from.

Attach hopper return tube to the fitting where the

suction set return tube was removed. The connec-

tion needs to be only hand tight.

5. Fit the hopper screen into the bottom of the hopper,

being sure it is properly seated.

Cleaning Hopper Unit

To clean the hopper unit:

1. Flush the pump and hose with water or solvent

following the same procedure as with the suction

tube, being sure the return tube is thoroughly flushed

out.

2. Clean the hopper screen with water or appropriate

solvent. If necessary use a nylon or natural bristle

brush dipped in solvent or soapy water.

3. Wash the hopper thoroughly using soapy water

for latex paint, the appropriate solvent with other

materials.

The hopper assembly consists of the hopper, hopper

return tube and hopper screen. To make the conversion:

1. Remove suction tube and return tube and brass

return tube fitting from the unit.

2. To convert the cart into its horizontal configuration

as shown in Figure 49, reverse the positions of the

handle and pail bracket.

3. Screw the hopper directly onto the inlet valve where

the suction tube was removed. Make the connection

hand tight, just tight enough to prevent paint leakage

or air suction around the threads.

NOTE: The hopper screen is essential to trap

debris and other foreign objects from entering

the pump. Do not operate the sprayer without

the screen properly in place.