6 Finish 230 AC Compact

GB

Safety Regulations General Description

1.2 Earthing Instructions

Electric models must be earthed. In the event of an electrical short

circuit, earthing reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having an earthing wire with an appropriate earthing plug. The

plug must be plugged into an outlet that is properly installed and

earthed in accordance with all local codes and ordinances.

DANGER — Improper installation of the earthing

plug can result in a risk of electric shock. If repair

or replacement of the cord or plug is necessary, do

not connect the green earthing wire to either blade

terminal. The wire with insulation having a green

outer surface with or without yellow stripes is the

earthing wire and must be connected to the earthing

pin.

Check with a qualied electrician or serviceman if the earthing

instructions are not completely understood, or if you are in doubt as

to whether the product is properly earthed. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

Caution – The power cord for this equipment acts as

an emergency stop/emergency switching o device.

The power cord must be placed near an easily

accessible, unobstructed socket-outlet.

1.3 Technical Data

Weight : 40.6kg(89.5lbs.)

Capacity : Upto1.69liters(0.45gallon)perminute

Power requirement :

Model0524009 : 10ampminimumcircuiton230-240VAC,

50Hzcurrent,1PH

Model0524019 : 10ampminimumcircuiton230VAC,50Hz

current, 1 PH

Power consumption : 1000W

Short circuit current

(SCC) : 8 amp

Max. uid pressure : Upto193bar(19MPa,2800PSI)

Max. air pressure : Upto2.1bar(0.21MPa,30psi)

Dimensions : 81.3cmx53.3cmx55.9cm(32”Lx21”Wx

22”H)

Noise level : lessthan70dB(A).

Vibration levels

Spray gun : < 2.5m/s

2

Cart handle : 6.5m/s

2

when unit is operating

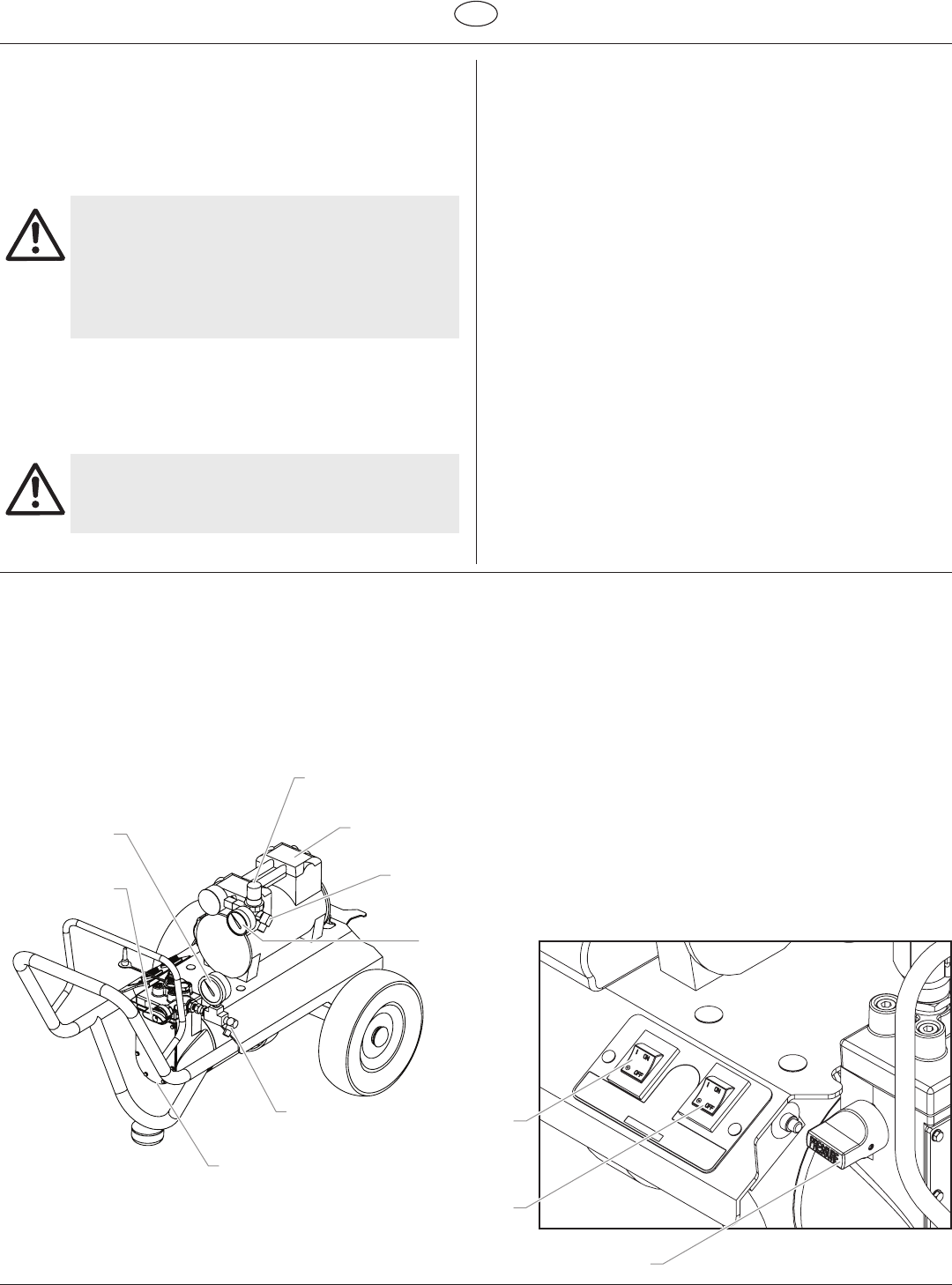

2. General Description

This ne nish spray system is versatile enough to use for low

pressure ne nish work as well as high pressure airless spraying. The

system includes a diaphragm paint pump and an air compressor that

work together to provide this versatility.

2.1 System Diagram

1

9

10

11

2

8

7

6

4

5

3

1

9

10

11

2

8

7

6

4

5

3

1 Material pressure gauge

2 PRIME/SPRAYvalve

3 Air pressure regulator

4 Air compressor

5 Air outlet tting

6 Air pressure gauge

7 Material outlet tting

8 Diaphragm pump

9 Compressor ON/OFF switch

10 Diaphragm pump ON/OFF switch

11 Pressure control knob