6 ProSpray 3.34

GB

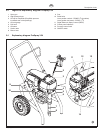

General view of application Description of unit

2. General view of application

2.1 Application

2.2 Coating materials

Processible coating materials

i

Pay attention to the Airless quality of the coating

materials to be processed.

Dilutable lacquers and paints or those containing solvents, two-

component coating materials, dispersions, latex paints.

Noothermaterialsshouldbeusedforsprayingwithout

WAGNER’sapproval.

Filtering

Despitesuctionlterandinsertionlterinthespraygun,ltering

of the coating material is generally advisable.

Stir coating material before commencement of work.

i

Attention: Make sure, when stirring up with

motor-driven agitators that no air bubbles are

stirred in. Air bubbles disturb when spraying and

can, in fact, lead to interruption of operation.

Viscosity

With this unit it is possible to process highly viscous coating

materials of up to around 25.000 MPa·s.

If highly viscous coating materials cannot be taken in by suction,

theymustbedilutedinaccordancewiththemanufacturer’s

instructions.

Two-component coating material

The appropriate processing time must be adhered to exactly.

Within this time rinse through and clean the unit meticulously with

the appropriate cleaning materials.

Coating materials with sharp-edged additional materials

These have a strong wear and tear effect on valves, high-

pressure hose, spray gun and tip. The durability of these parts

cane be reduced appreciably through this.

3. Description of unit

3.1 Airless process

The main areas of application are thick layers of highly viscous

coating material for large areas and a high consumption of

material.

A piston pump takes in the coating material by suction and

conveys it to the tip. Pressed through the tip at a pressure of

up to a maximum of 221 bar (22,1 MPa), the coating material

isatomised.Thishighpressurehastheeffectofmicrone

atomisation of the coating material.

As no air is used in this process, it is described as an AIRLESS

process.

Thismethodofsprayinghastheadvantagesofnest

atomisation, cloudless operation and a smooth, bubble-free

surface. As well as these, the advantages of the speed of work

and convenience must be mentioned.

3.2 Functioning of the unit

In the following there is a short description of the technical

construction for better understanding of the function.

WAGNERProSprayunitsareelectricallydrivenhigh-pressure

spraying units.

A gear unit transfers the driving force to a crankshaft. The

crankshaft moves the pistons of the material feed pump up and

down.

The inlet valve is opened automatically by the upwards

movement of the piston. The outlet valve is opened when the

piston moves downward.

Thecoatingmaterialowsunderhighpressurethroughthehigh-

pressure hose to the spray gun. When the coating material exits

fromthetipitatomizes.

The pressure regulator controls the volume and the operating

pressure of the coating material.

Materials Object Size

Model

PS 3.21

PS 3.23

PS 3.25

PS 3.29

PS 3.31

PS 3.34

PS 3.39

Releaseagents,oils,undercoats,primers,llers,

synthetic resin-based paints, acrylic paints

recommendednozzlesize:FineFinish0.008“-0.014“

up to 200 m

2

200 m

2

- 800 m

2

more than 800 m

2

Emulsion paints, latex paints

recommendednozzlesize:0.017“-0.027“

up to 200 m

2

200 m

2

- 800 m

2

more than 800 m

2

Anti-corrosiveagents,ameretardants,fabric

adhesive

recommendednozzlesize:0.021“-0.031“

up to 200 m

2

200 m

2

- 800 m

2

more than 800 m

2

Airless-scrapers

recommendednozzlesize:0.027“-0.039“

up to 200 m

2

200 m

2

- 800 m

2

more than 800 m

2

= Recommended =Not-recommended