GB

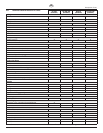

Remedy in case of faults

Type of malfunction

material is ejected only with an

upward stroke, or upward motion

of the piston rod is slow and

downward motion is fast

material is ejected only with a

downward stroke, or downward

motion of the piston rod is slow

and upward motion is fast.

C. Piston rod moves up and down

D. Piston rod moves up and down

slowly when the spray gun is

closed.

gun.

F. Piston rod sputters when stroking

upward or downward.

Possible cause

1. Inlet valve is leaky due to impurities or

wear.

2. Coating material viscosity is too high,

preventing it from being sucked up.

2. Lower packing is worn.

1. Suction tube projects over the uid

level and sucks in air.

2. Coating material viscosity is too high,

preventing it from being sucked up.

3. Ball in inlet valve housing is stuck.

1. Loose connections.

2. Relief valve is not closed completely.

3. Relief valve worn.

4. Lower packing worn.

5. Ball in inlet valve housing and ball

in outlet valve seat are not sealing

properly.

2. Filter cartridge in high-pressure lter

is clogged.

3. High-pressure hose is too long.

1. Solvent has made the upper packing

Measures for eliminating the malfunction

1. Clean and check the inlet valve housing. Insert ball and ll

1. Dismantle and check outlet valve seat. Insert ball and ll

2. Replace.

1. Rell the coating material

instructions.

3. Vent air from material feed pump and turn the relief valve

knob to the left (k Circulation).

1. Dismantle inlet valve housing, clean ball and valve seat.

Check all connections between the material feed pump

and spray gun.

p spray).

3. Replace

4. If the measures described above do not help, replace

lower packing.

5. Dismantle inlet valve housing and outlet valve seat. Clean

balls and valve seats.

1. Replace

2. Clean or replace the lter cartridge.

3. Reduce length.

1. Replace upper packing.

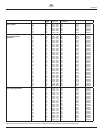

9.4 Material feed pump