5

The gas valve outlet pressure was pre-adjusted for both Nat. and LP at the factory, but ne adjustment

is possible by removing the access plug and turning the ne-adjustment screw with a 1/8" at blade

screwdriver. Adjustment must only be done while monitoring outlet pressure with a suitable manometer

properly attached to the outlet pressure tap. The outlet pressure tap must be leak checked after reseal-

ing (refer to Notes and Fig. 6 below).

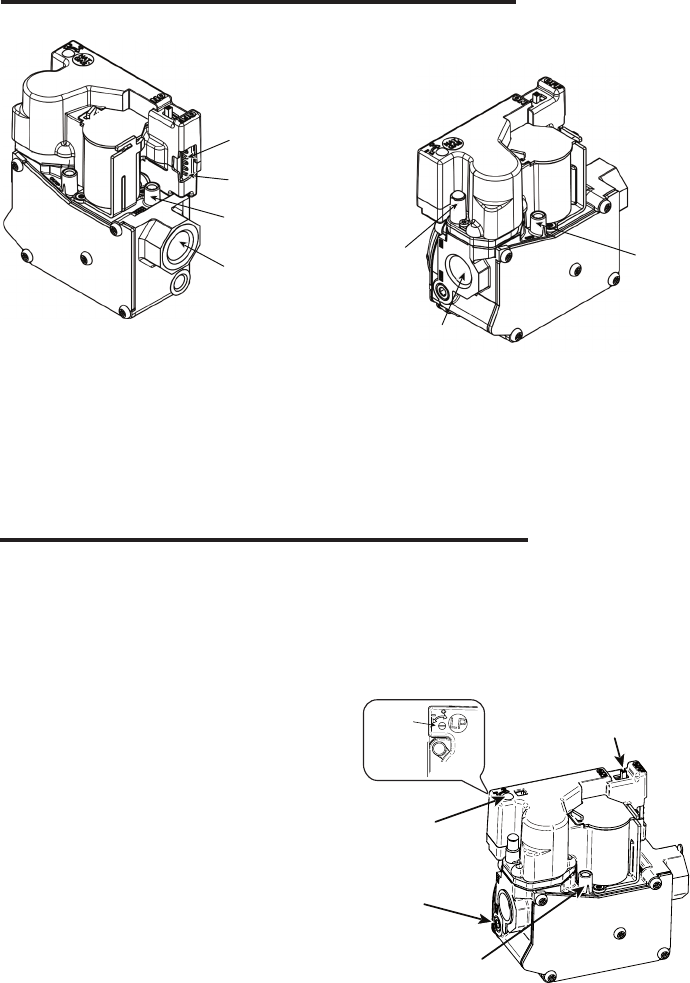

Fig. 6 – 36J27 Modulating Gas Valve

Fig. 5 – 36J27 Valve Features

OUTLET

PRESSURE

TAP POST

VALVE OUTLET

RE

GULATOR

VENT

ELECTRICAL

5 PIN CONNECTOR

PIN 1

LOCATION

INLET

PRESSURE

TAP POST

VALVE INLET

Electrical 5 PIN Connector Pin Out

PIN 5 - TH - Main Valve 24 VAC (top pin, with the cover pointing up)

PIN 4 - TR - Ground

PIN 3 - TX - Communication to IFC

PIN 2 - RX - Communication to Stepper

PIN 1 - TH - Board 24VAC (bottom pin, with the cover pointing up)

Notes:

1. The maximum outlet pressure adjustment using

the ne adjustment screw is approximately

±15% from the original factory setting.

2. The ne adjustment screw has 16 detents and

can be rotated innitely 360° in either direc-

tion. However, at some point in the rotation,

the outlet pressure will switch from +15% to

-15% or vice versa, depending on the direction

of rotation.

3. The ne adjustment screw aects the entire

modulation range. Therefore, once adjustment

is made, the valve outlet pressure must be

checked at both the minimum and maximum

extremes of the modulation range. (Refer to

the appliance manufacturer’s instructions.)

.093 SOCKET HEAD

SCREW OUTLET

PRESSURE TAP

(SOME MODELS)

1/8 - NPT OUTLET

PRESSURE TAP

(SOME MODELS)

ON/OFF SWITCH

ACCESS PLUG - (PRESSURE

FINE ADJUSTMENT SCREW

IS LOCATED BENEATH PLUG)

TURN SCREW

TO INCREASE /

DECREASE

OUTLET

PRESSURE

INSTALLATION

ADJUSTMENT