www.CH-Commercial.com

9

Installation (Continued)

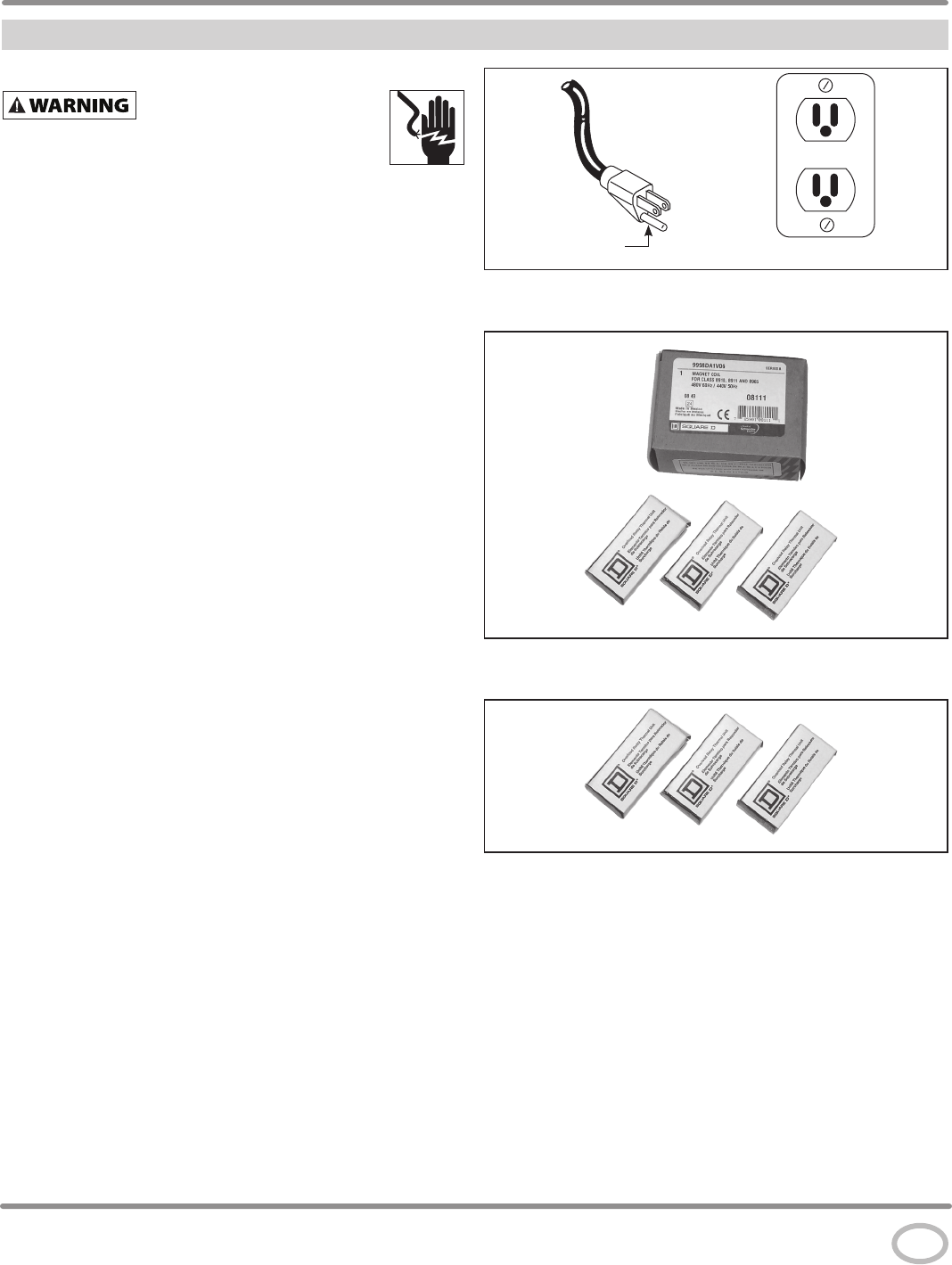

GROUNDING

Improperly grounded electrical

components are shock hazards.

Make sure all the components are properly grounded to

prevent death or serious injury.

This product must be grounded� Grounding reduces

the risk of electrical shock by providing an escape wire for the

electric current if short circuit occurs� This product must be

installed and operated with a power cord or cable that has a

grounding wire�

BREAKERS AND FUSES

The entire electrical system should be checked by a certified

electrician� Time delay breakers and fuses are required for this

compressor� A tripped breaker or blown fuses may indicate a

direct short to ground, high current draw, improper wiring,

incorrect fuse or breaker size and/or type� This needs to be

evaluated by a certified electrician�

MOTOR HOOKUP AND STARTER INSTALLATION

Branchcircuitprotectionmustbeprovidedasspecifiedin

the United States National Electrical Code, Chapter 2, “Wiring

DesignandProtection.”Article210,usingtheapplicablearticle

“ForMotorsandMotorControllers,”(Article430,Table430-1

52)�

IMPORTANT: Overload protection is required for all motors�

Motors used on CE7000, CE8000 and CE9000 Series air

compressors do not have built-in overload protection� A

magnetic starter is required� All CE Series compressors, except

models CE8000 and CE8002, include a magnetic starter� Refer to

the following wiring diagrams for electrical installation:

Shop Air Series Models - Figures 6 or 7

Automotive Series Models - Figures 8 or 9

Three phase motors are tri-voltage rated: 208-230/460� They are

shipped from the factory pre-wired for 208-230 volt operation� If

460 volt operation is desired, some rewiring is required�

Shop Air Series Models

1� Rewire the motor leads for 460 volt per motor data plate�

2� Install the 460 volt conversion kit provided with the unit�

Boththecoilandthethermaloverloadelementsinthe

magnetic starter must be changed (see Figure 11)�

Automotive Series Models

1� Rewire the motor leads for 460 volt per motor data plate�

2� Install the three thermal overload elements provided in the

conversion kit (see Figure 12)� The coil in the Automotive

Series models operates on 120 volts and does not have to be

changed�

Figure 11 - 460 Volt Conversion Kit - Shop Air Series

Figure 12 - 460 Volt Conversion Kit - Automotove Series

Figure 10 - Grounding

Grounded OutletGrounding Pin