release pressure from compressor

tank. Use your other hand to deflect

fast-moving air from being directed

toward your face.

3. The safety valve should automatically

close at approximately 40-50 psi. If the

safety valve does not allow air to be

released when you pull on the ring,

or if it does not close automatically, it

MUST be replaced.

Safety valve must

be replaced if it

cannot be actuated or it leaks air after

ring is released.

PRESSURE GAUGES

Gauge attached to regulator indicates

air pressure going to hose (and any tool

attached to end of hose).

Gauge attached to pressure switch

indicates air pressure in tank.

Maintenance

Release all pressure

and disconnect

power before making any repair.

1. Check compressor for any visible

problems, especially check air filter to

be sure it is clean.

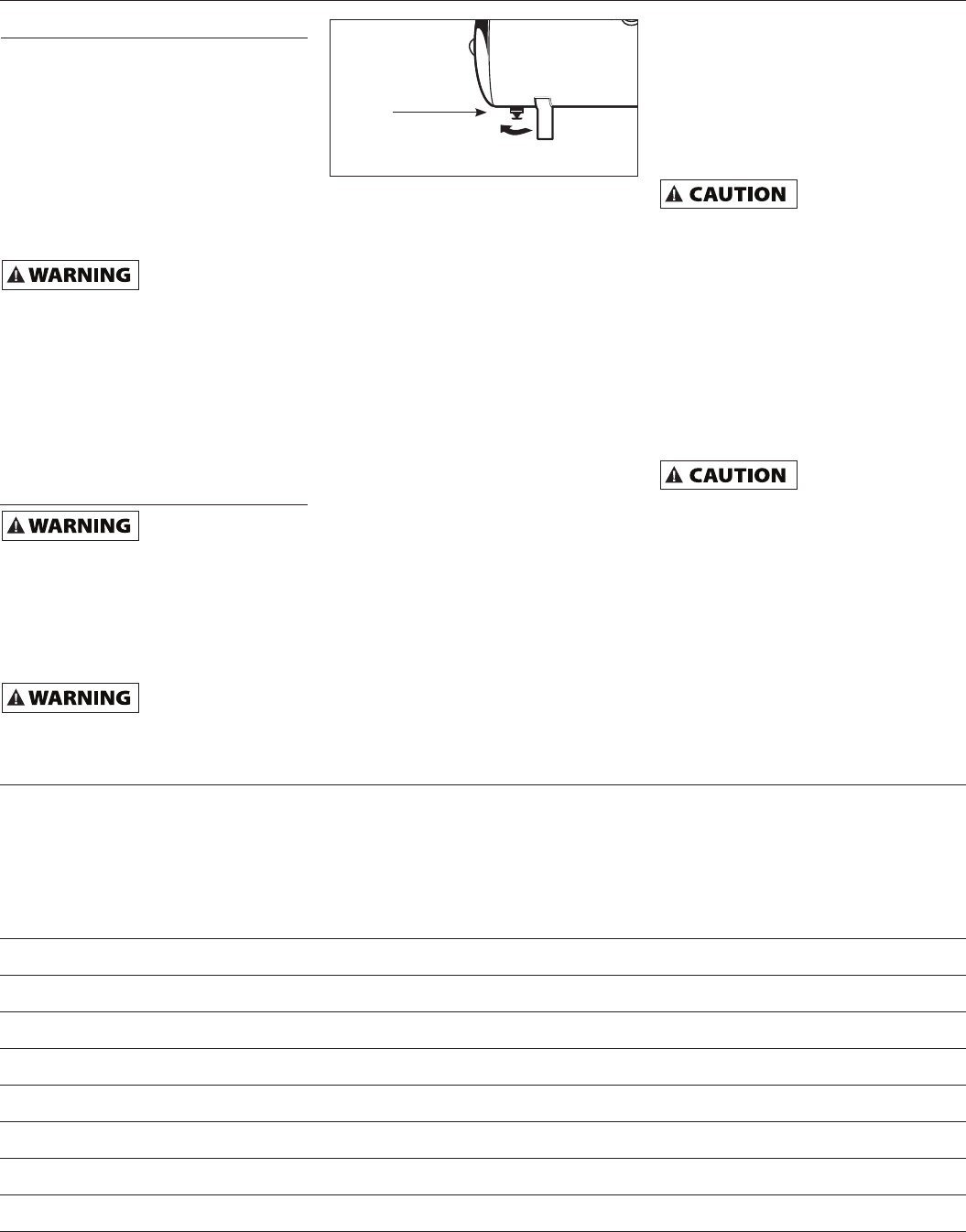

2. Pull ring on safety valve and allow it to

snap back to normal position (Figure 4).

Safety valve must

be replaced if it

cannot be actuated or it leaks air after ring

is released.

3. Daily with compressor shut off:

Depressurize system prior to draining

tank. Drain moisture from tanks by

opening drain cocks underneath end

of tanks.

4. Turn power OFF and clean dust and dirt

from motor, tank, air lines and pump

cooling fins.

NOTE: The air filter in the filter housing on

the side of the head must be checked and

cleaned periodically, more often if used

under very dusty conditions or when a

great deal of fog from spraying is allowed

to circulate near unit.

IMPORTANT:

Unit should be located as far

from spraying area as hose will allow to

prevent over-spray from clogging filter.

FILTER REMOVAL, INSPECTION AND

REPLACEMENT

To change a filter, pull off the filter

housing cover. If filter element is dirty,

rotate filter cover so the holes line up with

clean element material and snap cover

onto housing. If filter element has no clean

areas, replace element or entire filter.

LUBRICATION

This is an oilless type compressor requiring

no lubrication.

THERMAL OVERLOAD PROTECTOR

Turn off the pressure switch or unplug

compressor for 20 minutes and allow it to

cool. Unit should automatically reset.

This compressor is

equipped with

an automatic reset thermal overload

protector which will shut off motor if it

becomes overheated.

If thermal overload protector shuts

motor off frequently look for the

following causes.

1. Low voltage.

2. Wrong gauge wire or length of

extension cord.

3. Clogged air filter.

4. Lack of proper ventilation.

The motor must be

allowed to cool

down before start-up is possible. The

motor will automatically restart without

warning if left plugged into electrical

outlet, if the motor is turned on.

STORAGE

1. When not in use, hose and compressor

should be stored in a cool dry place.

2. Tank should be drained of moisture.

3. Hose should be disconnected and hung

open ends down to allow any moisture

to drain.

Notes

5

www.chpower.com

HM7500

Operation (Cont.)

Figure 5

Drain

Cock