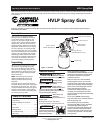

Figure 2 - Thin Material Needle And

Nozzle Kit

3. The all purpose material needle and

noz zle have three groove rings as

shown in Figure 3 below.

Figure 3 - All Purpose Material Needle

And Nozzle Kit

2

Operating Instructions and Parts Manual

Hazardous vapors: Paints,

solvents, insecticides, and

other materials may be

harmful if inhaled, causing

severe nausea, fainting, or

poisoning.

Use a respirator or mask whenever there is

a chance that vapors may be inhaled. Read

all instructions with the mask to ensure

that the mask will provide the necessary

protection against the inhalation of harmful

vapors.

NEVER point the spray gun at any part of

the body, or at anyone else.

!

CAUTION

Tipping the gun

causes the gun to clog. Dried spray material

also clogs the pressure delivery tube and

fittings. The spray gun does not function

when clogging occurs.

When not in use, be sure to disconnect the

hose and place the gun on a solid, level

surface to avoid tipping.

Components

(1) Gun - fully assembled, with all

purpose needle/nozzle installed

Setup

NEEDLE AND NOZZLE ASSEMBLY

1. Use Chart 1 to determine the

proper size nozzle and needle for

the material to be applied. The

all purpose needle and nozzle are

installed at the factory.

IMPORTANT: The needle and nozzle

are a matched as sem bly. It is very

important that both the needle and

nozzle are correctly selected and

installed. The nee dle/nozzle kits are

identified by groove rings ma chined

into both the needle, and the nozzle.

Make sure that the number of rings

in the noz zle and the needle match.

Failure to match these two com po nents

prop er ly results in poor finish quality.

2. The thin material needle and nozzle

have a single groove ring as shown

in Figure 2 below.

4. The thick material needle and

nozzle have 2 groove rings as shown

in Figure 4 below.

Figure 4 - Thick Material Needle Kit

Note: The all-purpose material needle

kit is included with the unit. The thick

and thin material needle kits are not

included, however these kits can be

purchased from the retail outlet that

sold the unit or call 1-800-626-4401.

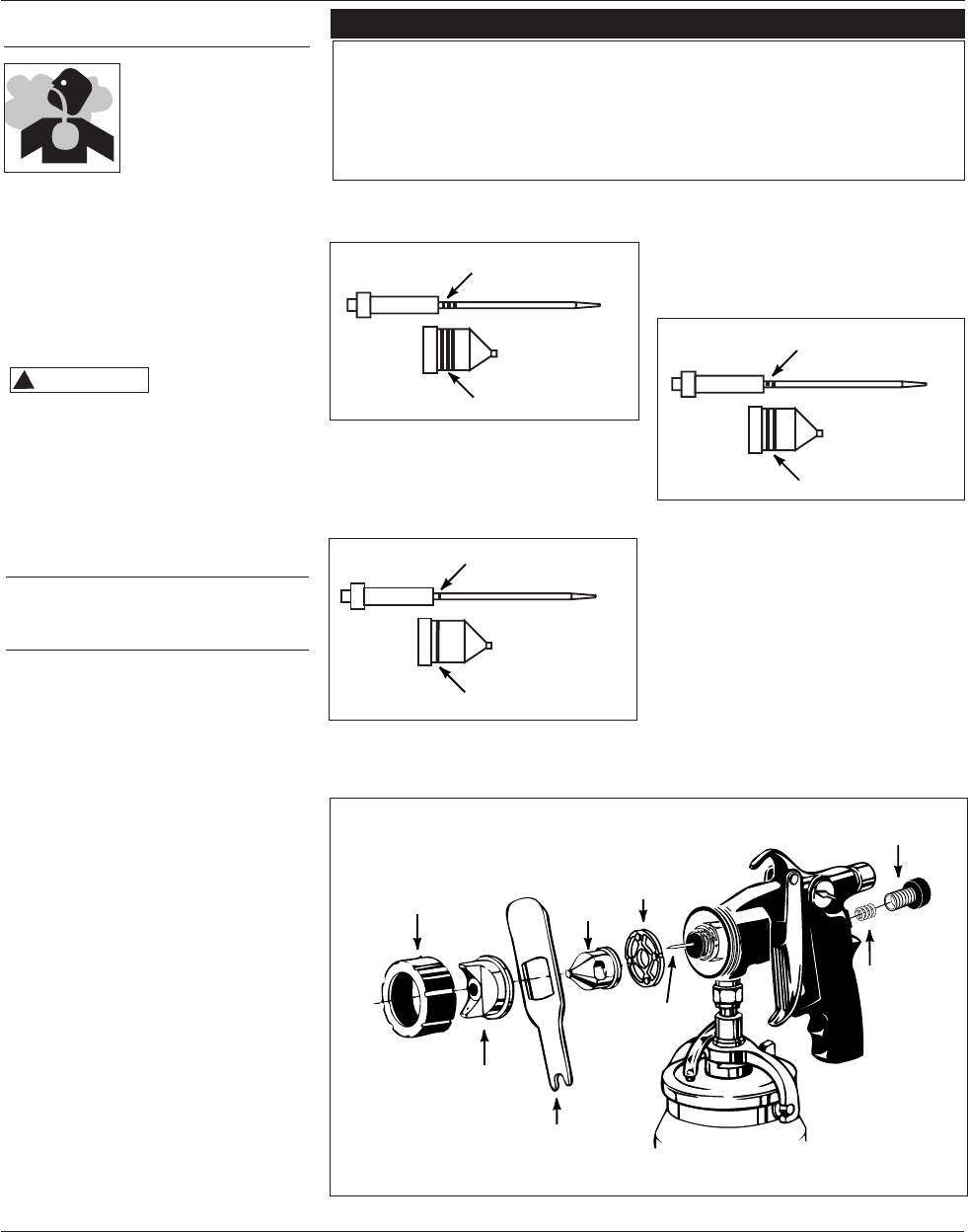

5. Remove the retaining ring, air

cap, noz zle, ma te ri al control knob,

spring, and needle as sem bly (Fig. 5).

Chart 1 - Material Needle/Nozzle Combination

SPRAYING MATERIAL NEEDLE/NOZZLE

Acrylics All purpose or Thin

Stains Thin

Sealers Thin

Lacquers Thin

Latex Paint All purpose

Oil Base Paint All purpose or Thick

(1) Groove Ring

(1) Groove Ring

(3) Groove Rings

(3) Groove Rings

(2) Groove Rings

(2) Groove Rings

Figure 5 - Needle/Nozzle Installation

Wrench

(located inside

storage

compartment)

Air Cap

Retaining

Ring

Nozzle

Air Flow

Ring

Needle

Assembly

Material Flow

Control Knob

Spring

General Safety (continued)

www.chpower.com