3

Single-Stage Compressor Pumps

www.chpower.com

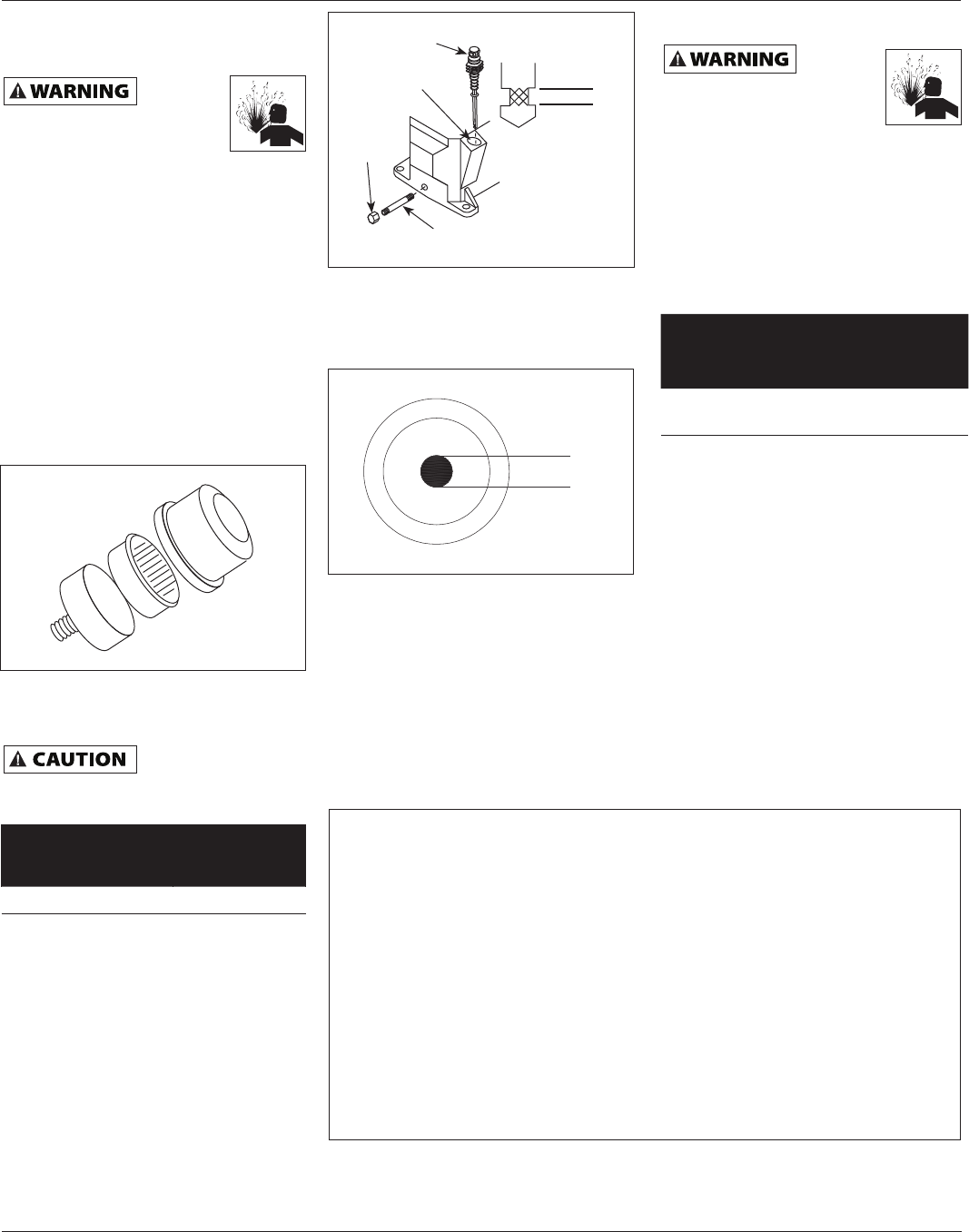

For pumps with an oil sight glass, oil

level can be monitored and maintained

as shown in Figure 3.

BREAK-IN

After installing compressor, start the

new pump and run without a load (0

PSI) for 30 minutes. With a pressure

regulator set to 40 PSI and no tool or

hose connected to the outlet, run the

compressor for another 30 minutes.

Maintenance

Release all pressure from the

system before attempting to

install, service, relocate or

perform any maintenance.

FOR EFFICIENT OPERATION BEFORE

EACH USE:

1. Check air filter.

2. Check oil level. Low oil level will

result in rapid wear and short pump

life.

TORQUE REQUIREMENTS (IN/LBS.)

Model

Compressor

Head Bolts

Bearing

Cap Bolts

All VT

models

175-225 50-120

TECHNICAL SERVICE

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

Assembly

ASSEMBLY INSTRUCTIONS

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

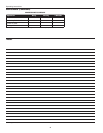

FLYWHEEL (VT2030 & VT2731 ONLY)

Place flywheel on the crankshaft with

setscrew threads on the outside. Tighten

setscrew to 19ft. lbs. on the key. Keep

the setscrew tight. A loose flywheel

causes a knocking noise.

AIR FILTER INSTALLATION

1. Screw inlet filter into 1/2” NPT

threaded inlet port on compressor

head.

LUBRICATION

This unit contains

no oil! Follow

lubrication instructions before

operating compressor.

Model

Approximate

Oil Capacity

(oz.)

VT4700 and VT4800 8.5

ALL MODELS

Ensure oil drain extension has been

installed (if included), then remove

the dipstick/breather and fill pump

with oil. Use SAE 30 Industrial Grade

compressor oil or full synthetic motor

oil like Mobil 1® 10W-30. Do not use

regular automotive oil such as 10W-30.

Additives in regular oil can cause valve

deposits and reduce pump life.

Proper oil fill is illustrated in Figure 2.

Figure 1 - Air Filter

Low

Max

Figure 2 - Oil Fill

Full

Add

Add Oil

Dipstick

Breather

Cap

Oil Drain Extension

(Not included with all models)

Figure 3

Full

Add Oil

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an

air compressor pump. When humidity is high or when a compressor is in

continuous use for an extended period of time, this moisture will collect in the

tank. When using a paint spray or sandblast gun, this water will be carried from

the tank through the hose, and out of the gun as droplets mixed with the spray

material.

IMPORTANT: This condensation will cause water spots in a paint job, especially

when spraying other than water based paints. If sandblasting, it will cause the

sand to cake and clog the gun, rendering it ineffective.

A filter in the air line, located as near to the gun as possible, will help eliminate

this moisture.