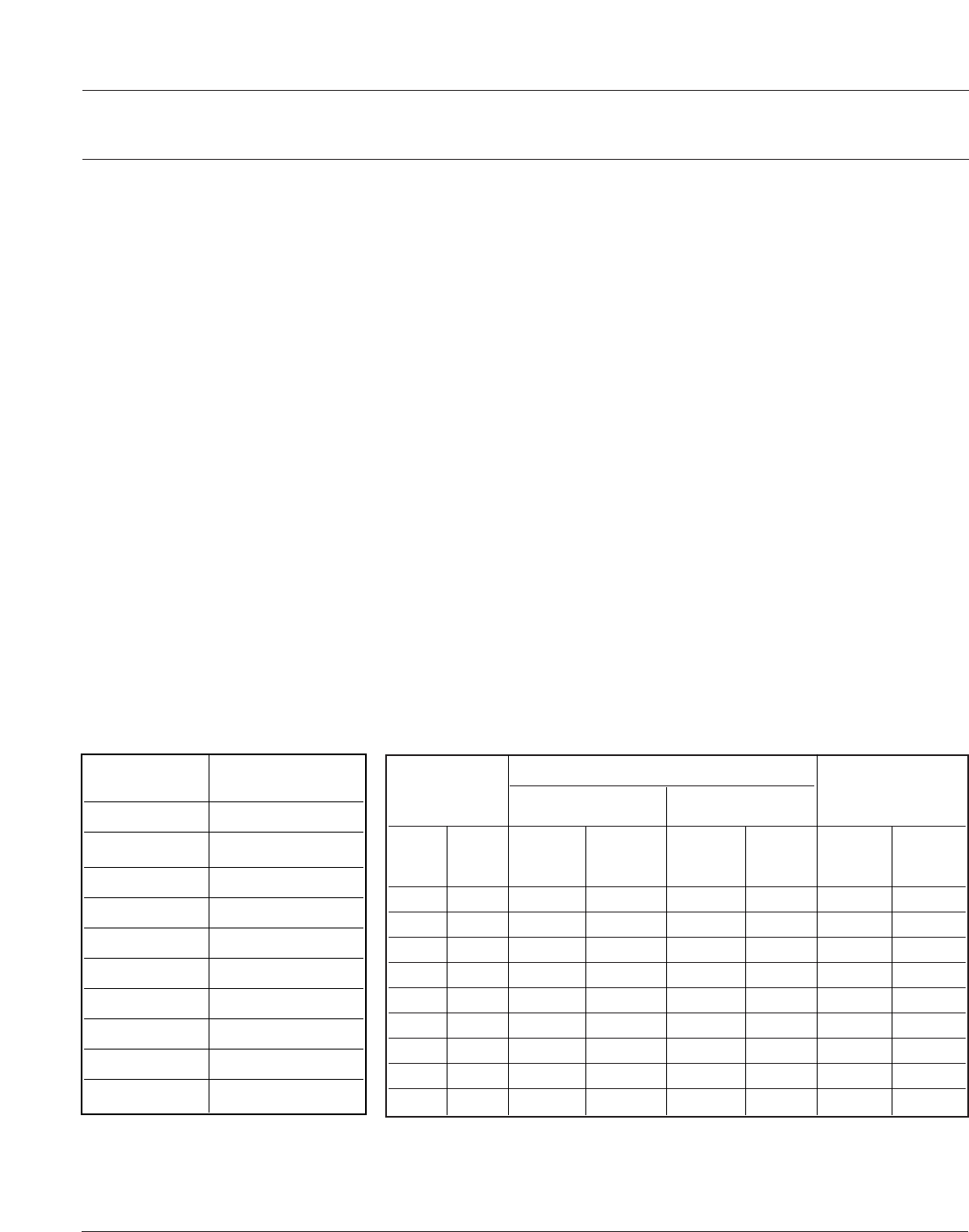

Electrode Direct Current (amps) Alternating Current

Diameter Electrode Negative Electrode Positive (amps)

Polarity Polarity

Tungsten Tungsten Tungsten

(in) (mm) Pure with Pure with Pure with

Tungsten Oxides Tungsten Oxides Tungsten Oxides

0.02 0.5 2-20 2-20 N/A N/A 2-15 2-15

0.04 1.0 10-75 10-75 N/A N/A 15-55 15-70

1/16 1.6 40-130 60-150 10-20 10-20 45-90 60-125

5/64 2.0 75-180 100-200 15-25 15-25 65-125 85-160

3/32 2.4 130-230 170-250 17-30 17-30 80-140 120-210

1/8 3.2 160-310 225-330 20-35 20-35 150-190 150-250

5/32 4.0 275-450 350-480 35-50 35-50 180-260 240-350

3/16 5.0 400-625 500-675 50-70 50-70 240-350 330-460

1/4 6.3 550-875 650-950 65-100 65-100 300-450 430-575

Striking an arc:

Turn on the welder and the gas valves

on the gas bottle, regulator, and torch.

Rest the torch nozzle on the base

metal to be welded without the

Tungsten electrode touching the base

metal.

Rotate the torch so that the Tungsten

electrode lightly touches the base

metal and immediately lift off or rotate

off as the arc ignites.

Keep the Tungsten 1/8” - 3/16” from

the work piece while maintaining the

arc.

As the metal gets hot, it becomes a

shiny orange molten puddle. Dip the

filler metal rod in the puddle to add

filler metal.

Model WT6100

5

Pre-TIG Welding tips:

TIG welding is much harder to master

than other welding processes.

Experience welding with an Oxy-

Acetylene (flame power) torch will help

greatly with learning TIG welding.

CLEAN the area to be welded.

Cleanliness is imperative. You can’t get

the base metal too clean. There is no

flux to float off impurities with the TIG

process.

Cut filler metal rods to shorter lengths

for easier control. Usually TIG filler

metal comes in 36” lengths. It is much

easier to handle if it is 18” or 12”. Clean

the filler metal with alcohol and a clean

white cloth. Dirt and dust contaminate

a weld.

TIG welding gives off less light than

other arc welding processes, but you

must still use a #10 minimum shade

welding lens to protect your eyes.

Get yourself into a comfortable

position to weld. Seated with your arms

supported by a welding table or by the

work-piece.

Tips while TIG welding:

Always let the filler metal rod be

melted by the molten puddle. NOT

by the torch.

Never touch the hot Tungsten

electrode to the molten puddle. The

molten steel will be wicked up by the

Tungsten, contaminating the electrode.

When you contaminate the Tungsten

with steel, stop welding and re-grind

the point of the electrode, removing

the steel contamination.

When you burn a hole through the

base metal, stop welding and let the

weld cool before re-starting the arc.

Before making an important TIG weld,

practice on a test piece. TIG welding is

an art, and practice improves quality.

There is a lot of self-satisfaction to

mastering this welding process and

seeing that perfect weld.

www.chpower.com

Identifcation

Color

Oxide

Green None

Blue 0.4% ThO

2

Yellow 1.0% ThO

2

Red 2.0% ThO

2

Violet 3.0% ThO

2

Orange 4.0% ThO

2

Brown 0.3% ZrO

2

White 0.8% ZrO

2

Black 1.0% LaO

2

Grey 2.0% CeO

2

TIG Electrode Identification Recommended TIG Parameters for Optional Electrodes