Page 4

For technical questions, please call 1-800-444-3353.

SKU 67501/68740

operate it. A compressor is dangerous in the

hands of untrained users.

d. Maintain the compressor. Keep the compressor

clean for better and safer performance.

Following instructions for lubricating and

changing accessories. Keep dry, clean and free

from oil and grease. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

compressor’s operation. If damaged, have

the compressor repaired before use. Many

accidents are caused by a poorly maintained

compressor.

e. Use the compressor in accordance with these

instructions, taking into account the working

conditions and the work to be performed.

Use of the compressor for operations different

from those intended could result in a hazardous

situation.

5. Service

a. Have your compressor serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the

compressor is maintained.

Air Compressor Safety Warnings

1. Risk of re or explosion - Do not spray ammable

liquid in a conned area or towards a hot surface.

Spray area must be well-ventilated. Do not smoke

while spraying or spray where spark or ame is

present. Arcing parts - Keep compressor at least

20 feet away from explosive vapors, such as when

spraying with a spray gun.

2. Risk of bursting - Do not adjust regulator higher

than maximum stated pressure of attachment.

3. Risk of injury - Do not direct air stream at people or

animals.

4. To reduce the risk of electric shock, do not expose

to rain. Store indoors.

5. Wear ANSI-approved safety goggles during use.

6. Do not use to supply breathing air.

7. Do not use the air hose to move the compressor.

8. Drain Tank daily and after use. Internal rust causes

tank failure and explosion.

9. Add correct amount of compressor oil before rst

use and every use. Operating with low or no oil

causes permanent damage and voids warranty.

10. Do not remove the Pressure Switch (54) cover or

adjust the internal components.

11. Do not use the air hose to move the compressor.

12. Compressor head gets hot during operation. Do

not touch it or allow children nearby during or

immediately following operation.

13. Release the pressure in the storage tank before

moving.

14. The use of accessories or attachments not

recommended by the manufacturer may result in a

risk of injury to persons.

15. All air line components, including hoses, pipe,

connectors, lters, etc., must be rated for a

minimum working pressure of 150 PSI, or 150%

of the maximum system pressure, whichever is

greater.

16. USE OF AN EXTENSION CORD IS NOT

RECOMMENDED. If you choose to use an

extension cord, use the following guidelines:

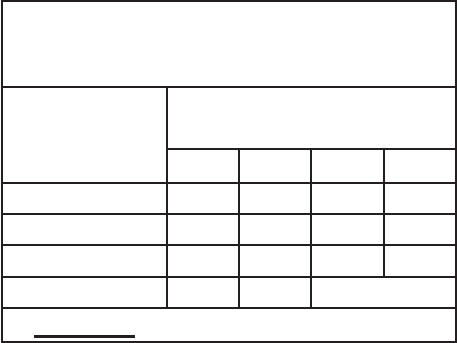

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS

(120 VOLT)

NAMEPLATE

AMPERES

(at full load)

EXTENSION CORD

LENGTH

25’ 50’ 100’ 150’

0 – 6 18 16 16 14

6.1 – 10 18 16 14 12

10.1 – 12 16 16 14 12

12.1 – 16 14 12 Do not use.

TABLE A

a. Make sure your extension cord is in good

condition.

b. Be sure to use an extension cord which is heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

Table A shows the correct size to use depending

on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

17. Industrial applications must follow OSHA

guidelines.

18. Maintain labels and nameplates on the compressor.

These carry important safety information. If

unreadable or missing, contact Harbor Freight

Tools for a replacement.

19. This product is not a toy. Keep it out of reach of

children.

20. Operate unit on level surface. Check oil level daily

and ll to marked level if needed.

21. People with pacemakers should consult their

physician(s) before use. Electromagnetic elds in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.